Adjustable accurate-position scraper device

A technology of precise positioning and scraper device, used in scraper, moving filter element filter, filter separation, etc., can solve the problems of large cumulative error of scraper drive device, complex motion structure, and reduced spring performance, to overcome punching and chamfering. The effect of precise machining, spacing adjustment, and improved motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

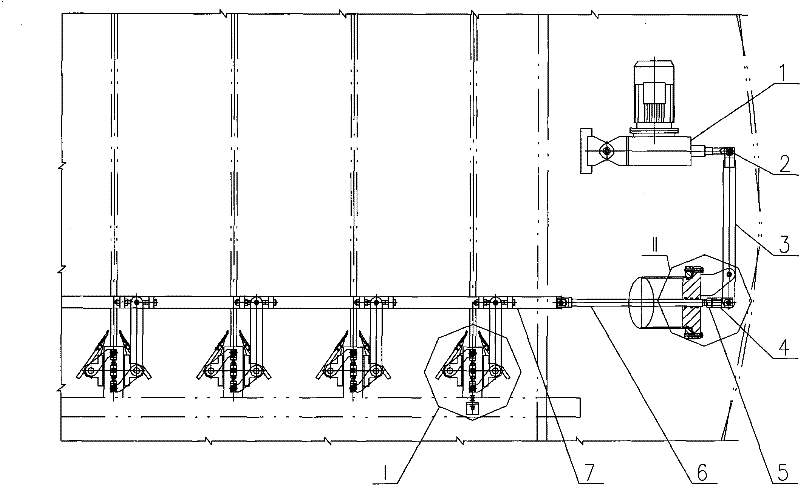

[0020] The present invention is described below in conjunction with the accompanying drawings.

[0021] See attached figure 1 , the present invention is made of motor and speed change device 1, bearing pin 2, head rocking arm 3, connecting fork 4, lock nut 5, power bar 6, propulsion bar 7 and by the scraper of I part and relevant device.

[0022] See attached figure 2 , In the scraper and related devices, the scraper holder drive rocker 11 is fixed by the nut 8, the connecting pin 9 and the adjustment screw 10, and the connection with the push rod 7 is realized. Fix bearing blocks 13 and 21 with screws 12. Scraper frame 14 and 24 are fixed knife frame rocking arms 16 and 23 with connecting key 15 and hinge. The scraper frame driving rocker arm 11 is hingedly connected with a scraper rocker arm, and both the scraper frame driving rocker arm and the blade frame rocker arm are assembled on the scraper frame shaft and connected by keys, when the motor and the axial reduction d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com