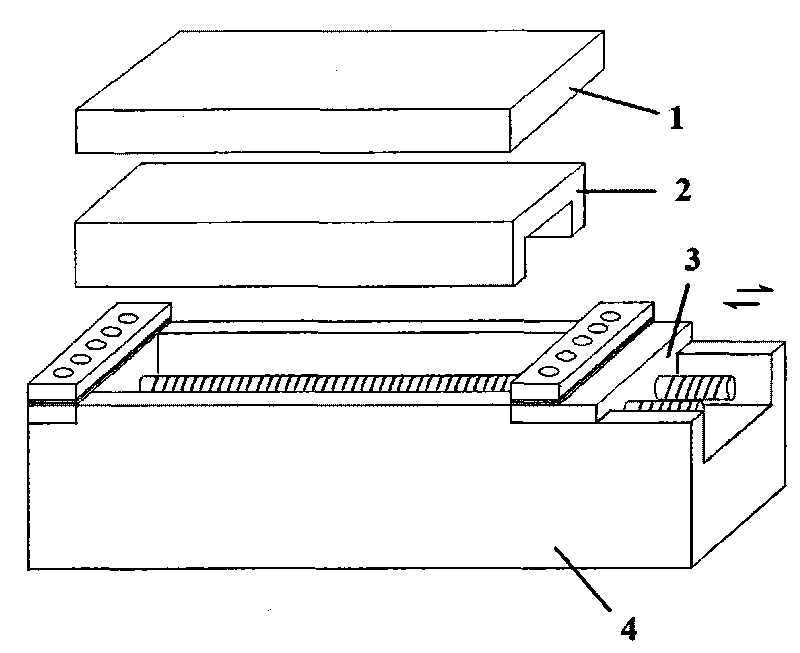

Preparation method of interplantation shape memory alloy wire layering composite and shaping mould

A technology of memory alloy wire and composite material, applied in the field of fiber reinforced composite material sheet, can solve the problems of bulky device structure, SMA strain variation, limited structure types, etc., and achieve the effect of shortening the processing process and improving the implantation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

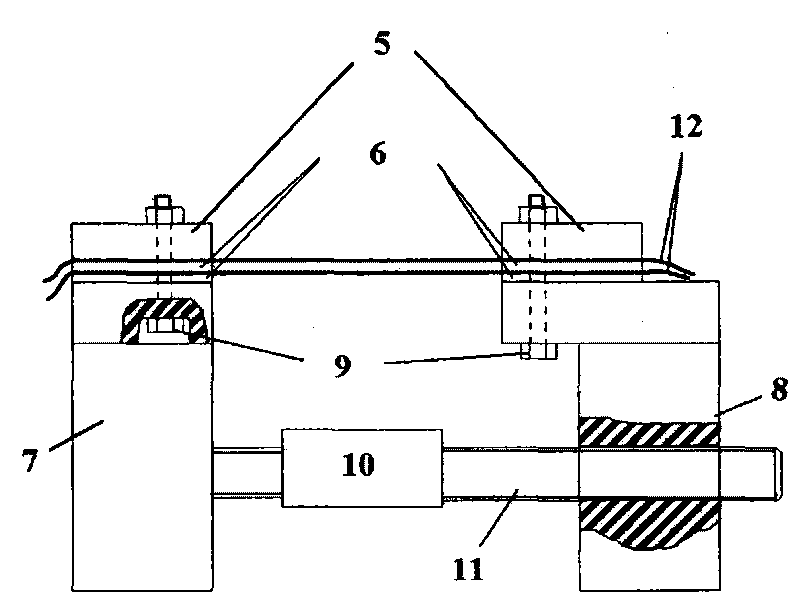

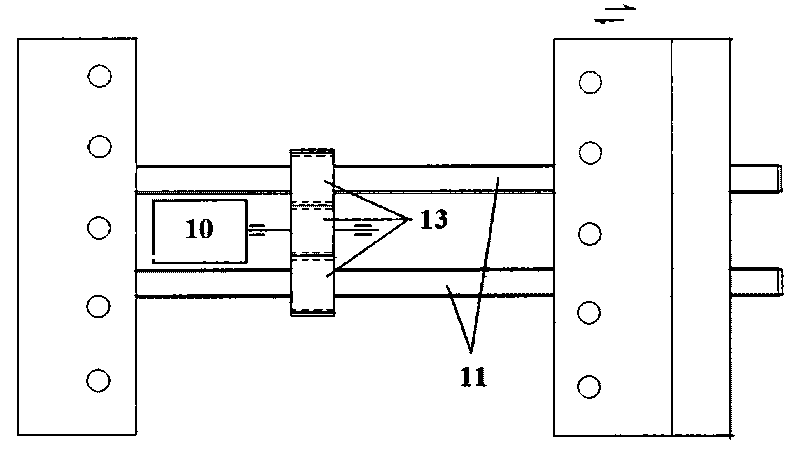

Method used

Image

Examples

Embodiment 1

[0031] Use glass fiber / epoxy unidirectional tape to prepare a laminated composite material plate with 12 layers of parallel layup, the designed molded thickness is 1.2mm, and the diameter of the multiple shape memory alloy wires used is 0.2mm, and the thickness is 5 % elongation, implanted in parallel to a depth of about 0.4mm from the surface of the plate. During preparation, lay 8 layers of unidirectional tape according to the pre-design, then arrange the shape memory alloy wires, select the thickness of the spacer on the steel frame assembly to be 0.8mm, continue laying the remaining 4 layers, and clamp the steel frame on the left For the chuck, apply a pre-tension of 0.5N to each shape memory alloy wire from the right, and clamp the right chuck; set the stepper motor stroke to 5% of the length of the composite material, and start heating after the pre-stretching is stable Pressurized equipment, compression molding. Through observation, the position and state of the shape ...

Embodiment 2

[0033] Prepare a 6-layer glass fiber plain weave / epoxy composite material plate with a thickness of 2.4mm. The diameter of the multiple shape memory alloy wires used is 0.2mm, and the elongation rate is 5%, and they are implanted in parallel at about 0.4mm from the surface of the plate depth. During preparation, first lay 4 layers of glass fiber plain cloth on the lower mold and then plant shape memory alloy wires. The method is the same as in Example 1. After all the glass fiber cloths are laid, pour the prepared epoxy resin glue, adjust Temperature and pressure, compression molding. Micrographs show that the shape memory alloy wire can still maintain a straight and parallel state, and its implantation position basically meets the design requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com