Welding device

A technology for welding devices and connecting rods, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as operator fatigue and difficulty in adjusting welding positions, and achieve reliable clamping, low manufacturing costs, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail:

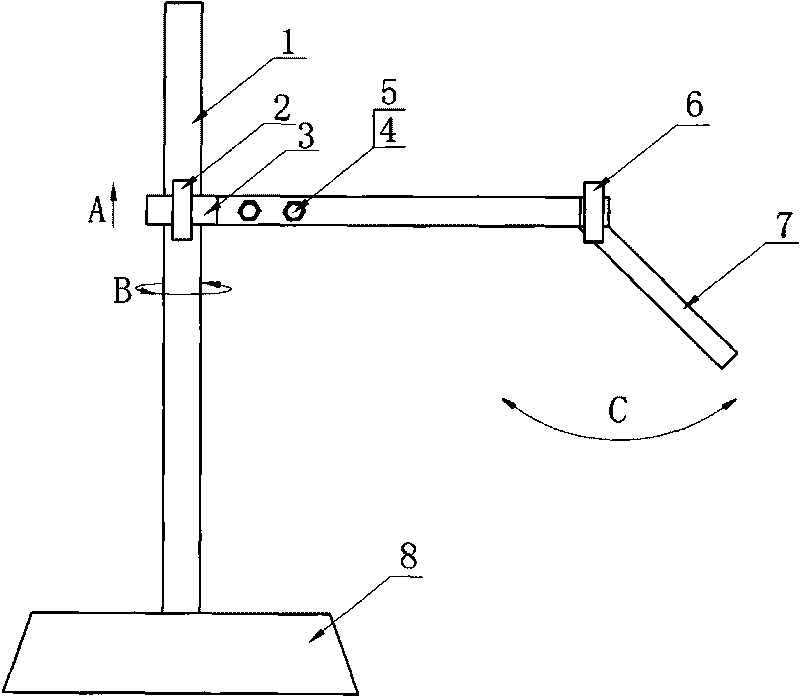

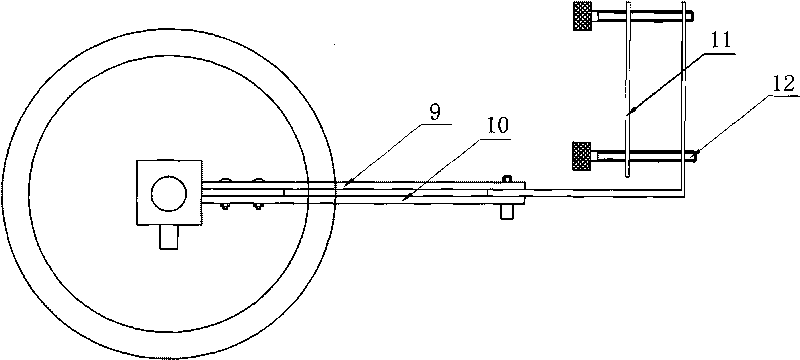

[0019] figure 2 , 3 It is the front view and top view of the welding device of the embodiment of the present invention. As shown in the figure, the welding device is composed of a bracket 1, a cross arm, connecting rods 9, 10, a rotating arm 7, a splint 11, a clamping knob 12 and the like. Wherein, support is made up of support 1 and base 8, and support 1 is cylindrical, and one end is screw rod, and support 1 is connected and fixed with the screw hole that base 8 center is provided with through screw rod to form stable support.

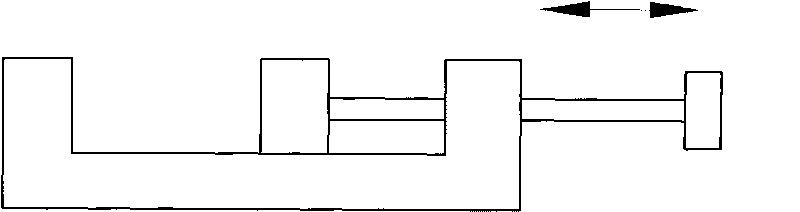

[0020] The transverse arm is made up of the first connecting rod 9, the second connecting rod 10 and the slider 3, and the two connecting rods clamp the protruding part connection block 3.1 of the slider 3 therein and are fixed by screws. The first connecting rod 9 and the second connecting rod 10 have the same shape and size, the differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com