Composite molding preparation method of three-component phononic crystal

A technology of phononic crystals and compound molding, which is applied in the direction of sound-producing devices and instruments, can solve the problems of limiting the application research of three-component phononic crystals and hindering the development of three-component phononic crystal technology, so as to promote rapid development and achieve sustainable development. Strong design and uniform interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

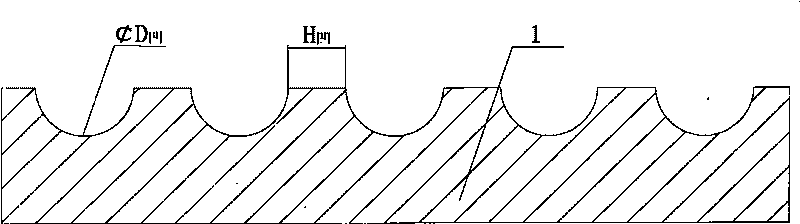

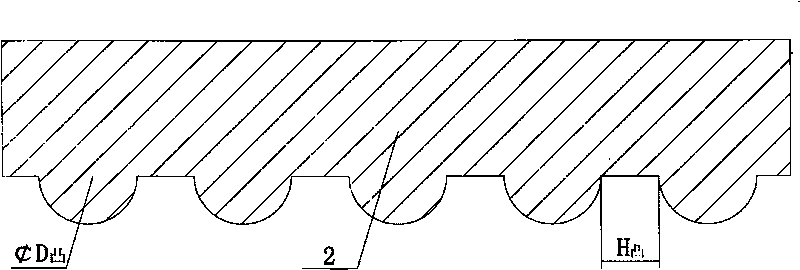

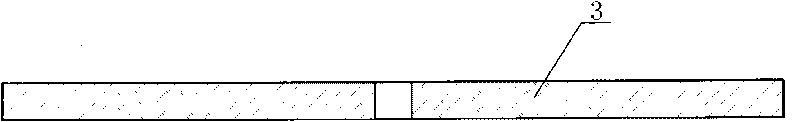

[0045] A compound molding preparation method of a three-component phononic crystal of the present invention includes a structural design method of a mold and a composite preparation method of a three-component phononic crystal that is deployed around the mold, and the mold is composed of a first forming plate 1 and a second forming plate 2 , the third forming plate 3, the fourth forming plate 4 and the fifth forming plate 5 respectively, the first forming plate 1 and the second forming plate 2 prepare the two-element phononic crystal composed of the vibrator and the cladding, and the third forming The plate 3 , the fourth forming plate 4 and the fifth forming plate 5 prepare a three-element phononic crystal composed of a two-element phononic crystal and a matrix. It can be seen from the described method that the present invention actually includes a two-component forming method.

[0046] Mold is owing to be made up of the first molding board 1, the second molding board 2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com