Novel clutch driven disc intersection angle expansion damping device

A damping device, clutch technology, applied in clutches, friction clutches, mechanical drive clutches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

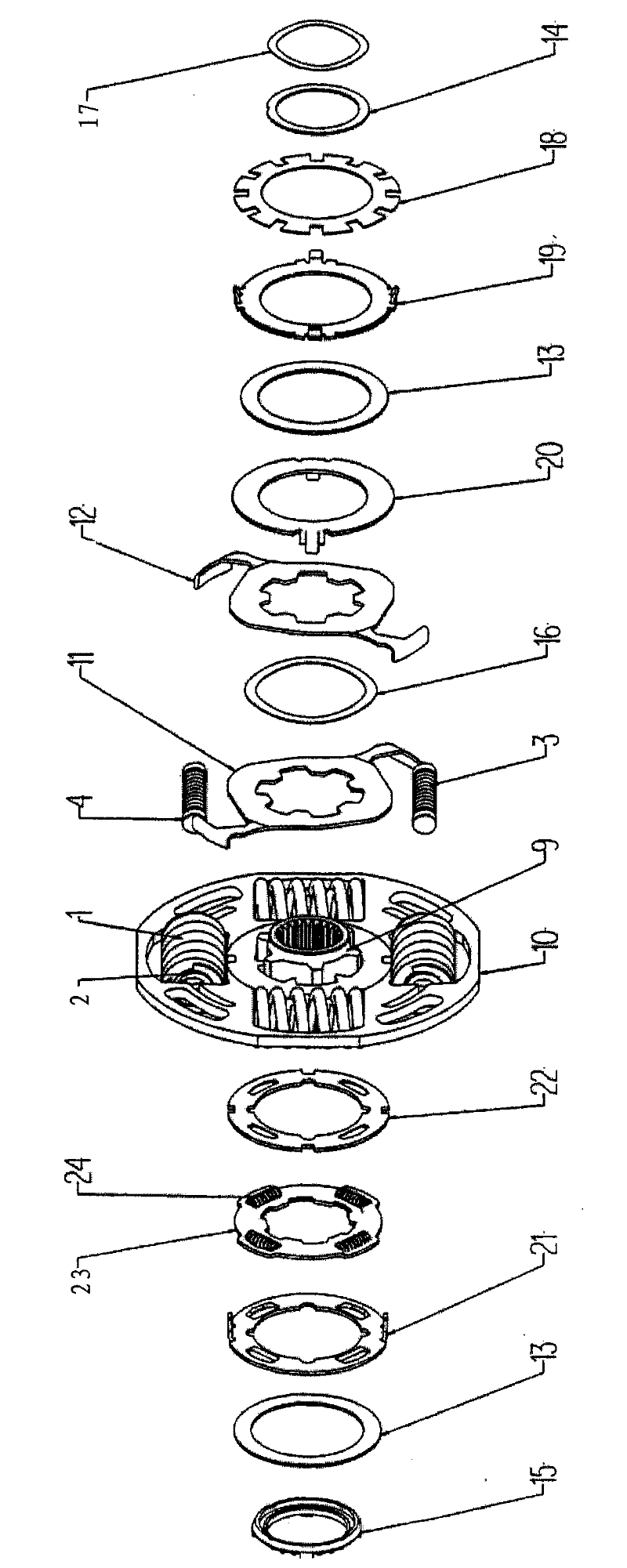

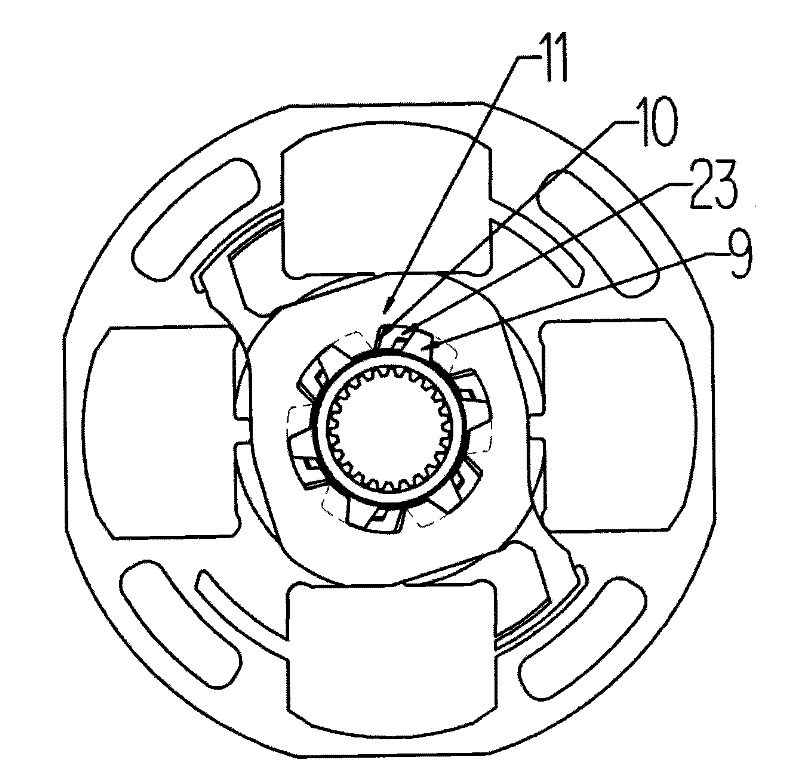

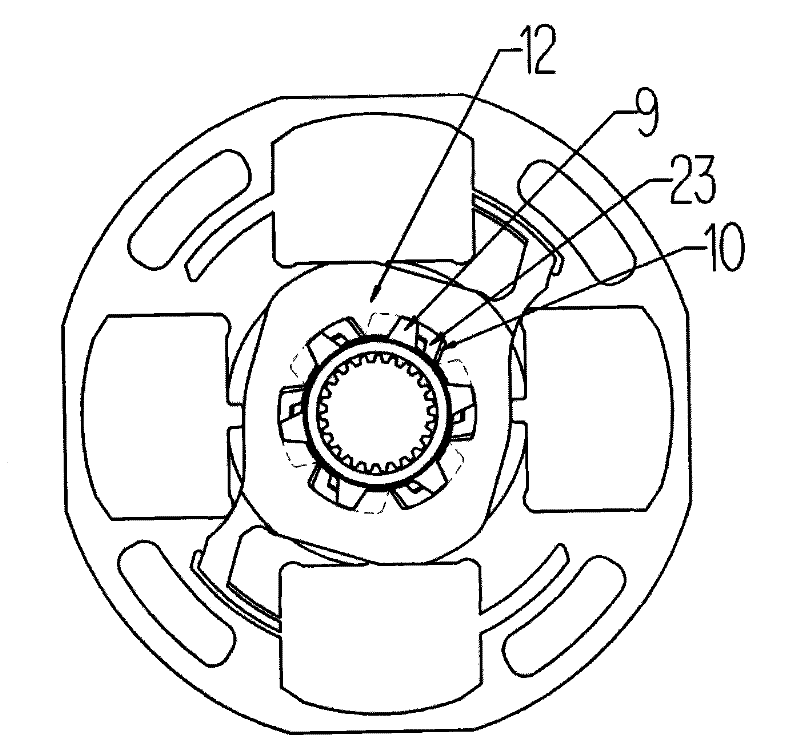

[0040] Please refer to the accompanying drawings for a further description of the present invention.

[0041] Such as figure 1 As shown, the present invention provides a new type of clutch driven disc expansion angle damping device, including a main shaft sleeve plate 10, a pre-damping sleeve plate 22 and a spline sleeve 9, on one side of the main shaft sleeve plate 10 One side is provided with a pre-vibration bushing plate 23, the other side is provided with a first-stage positive bushing plate 11 and a first-stage reverse bushing plate 12, a pre-vibration damping bushing plate 23, a main shaft bushing plate 10, and a first-stage forward bushing plate 10. The bushing plate 11 and the primary reverse bushing plate 12 are connected in series with the spline bushing 9 in the form of spline teeth, and the spline bushing 9 is connected with the input shaft of the gearbox.

[0042] The first-stage forward bushing plate 11 and the first-stage reverse bushing plate 12 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com