Composite air pressure balance tool tube

A technology of air pressure balance and tool pipe, which is applied in the field of tool pipe, can solve problems such as prone to landslides, inability to ensure the safety of operators, and inability to maintain the stability of the front soil, so as to achieve the effect of easy adaptive adjustment and easy balance control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

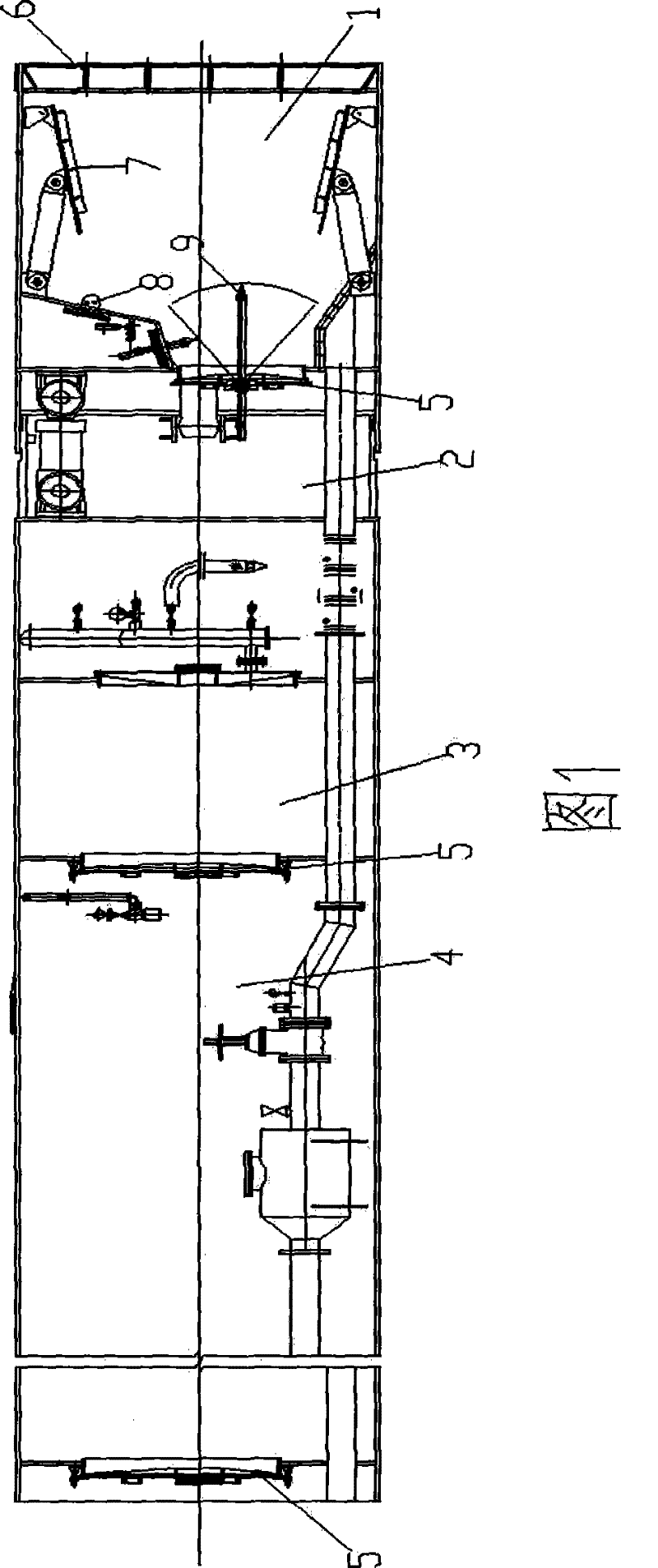

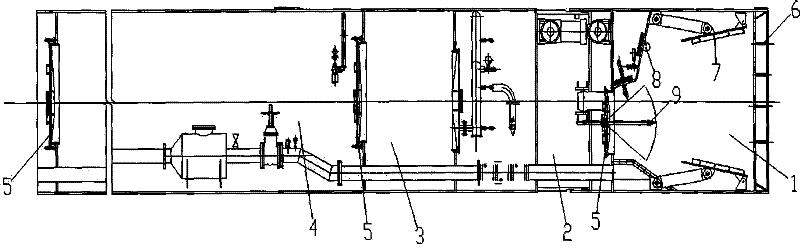

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] like figure 1 As shown, the composite air pressure balance tool pipe includes steel pipes and oil cylinders. Every two sections of steel pipes are connected by four sets of eight 800KN oil cylinders in total. The inside of the entire tool pipe is divided into excavation cabin 1, operation cabin 2, and decompression cabin in turn. 3. There are four parts of the material cabin 4, each cabin is sealed and isolated by steel plates, and a watertight gate 5 is set in the center of the isolation steel plate. Air protection system is connected.

[0026] The composite air pressure balance tool tube of the utility model: the two sections have no hinge, and the front and rear sections have the functions of full air pressure, partial air pressure, deviation correction, grouting, sealing, and blasting rock formations.

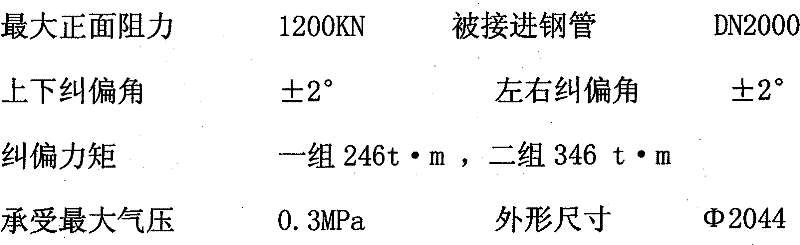

[0027] Its main technical performance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com