Covering layer forming method of blind ore bodies

An overburden and ore body technology, applied in the field of underground mining, can solve problems such as high caving costs and large ore dilution, and achieve the effects of controlling waste rock mixing, large block size, and simple stope structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Further illustrate the essence of the present invention with example below

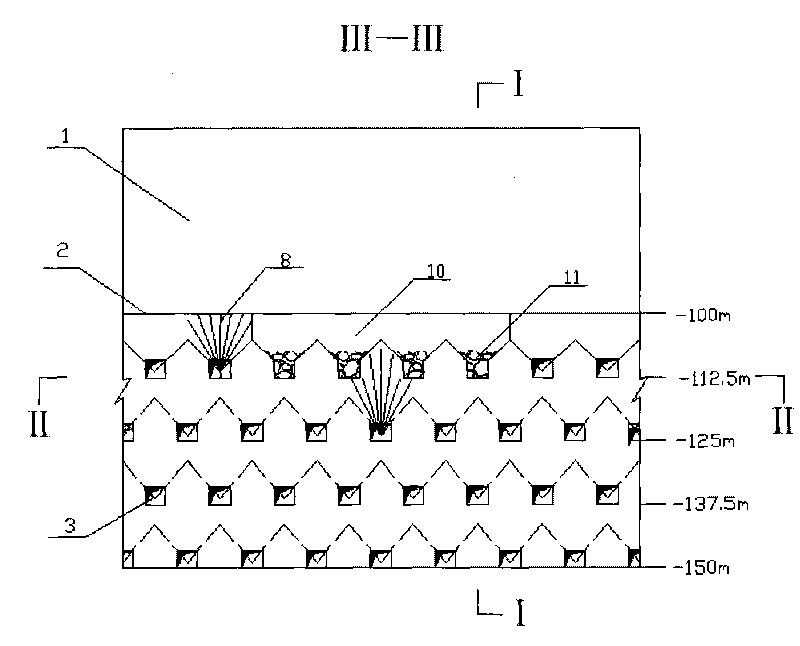

[0017] Figure 1 ~ Figure 3 The first blind ore body has an average horizontal thickness of 100 meters, and the roof rock 1 has good stability.

[0018] The sub-level caving method without pillars is used for mining. The stage height is 50 meters, the sub-section height is 12.5 meters, and the distance between the roads is 12.5 meters. The continuous goaf formed by the first sub-section mining roadway is used to induce the roof rock to caving and form a covering layer. .

[0019] exist figure 1 and image 3 The first segment (-112.5 meters) is arranged in the ore body, and the distance from the upper ore body boundary 2 is 12.5 meters, and the segments -125 meters and -137.5 meters are arranged sequentially from top to bottom.

[0020] figure 2 In -112.5 meters ~ -150 meters horizontal excavation mining roadway 3, the distance between the mining roadways is 12.5 meters, and rock drilling,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com