Method for constructing soft soil foundation continuous caisson

A construction method and caisson technology, which is applied in the direction of caisson, infrastructure engineering, construction, etc., can solve the problems of large amount of concrete sealing and chiseling, easy damage to the caisson wall, and large material loss, so as to save waste treatment and dismantle Ease of operation and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, take the construction of underground space of subway station as example, describe a specific embodiment of the present invention in detail.

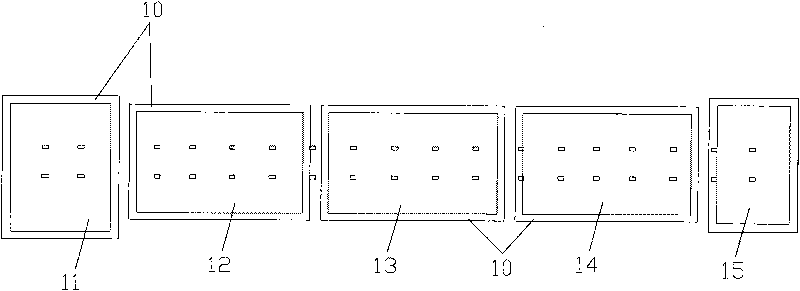

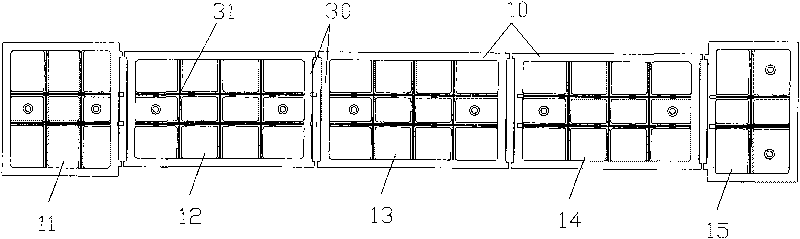

[0029] Such as figure 1 As shown, five individual caissons 11 , 12 , 13 , 14 , 15 arranged linearly along the longitudinal direction of the planned subway station. The transverse width along the station is the same as the subway station width, and the longitudinal length should be 1.5 to 2.5 times the station width.

[0030] Three caissons 12, 13, 14 of the same type are used in the standard section of the subway station, each approximately 22.80m×36m. Two separate caissons 11 and 15 are respectively formed in the shield working wells at the two ends of the subway station, and the distance between the adjacent two separate caissons is generally about 2 meters.

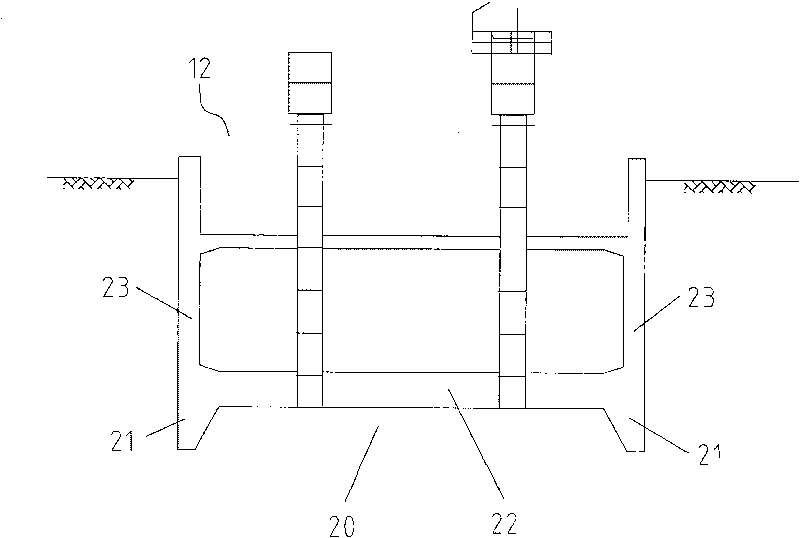

[0031] The thickness of the side wall 10 of the caisson facing the soil is set as follows: the thickness of the first und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com