Settling separation device and method

A technology of sedimentation separation and filtration device, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of increased filtration resistance and reduced separation efficiency, so as to speed up the reaction speed, improve the filtration effect, and improve the filtration effect and separation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

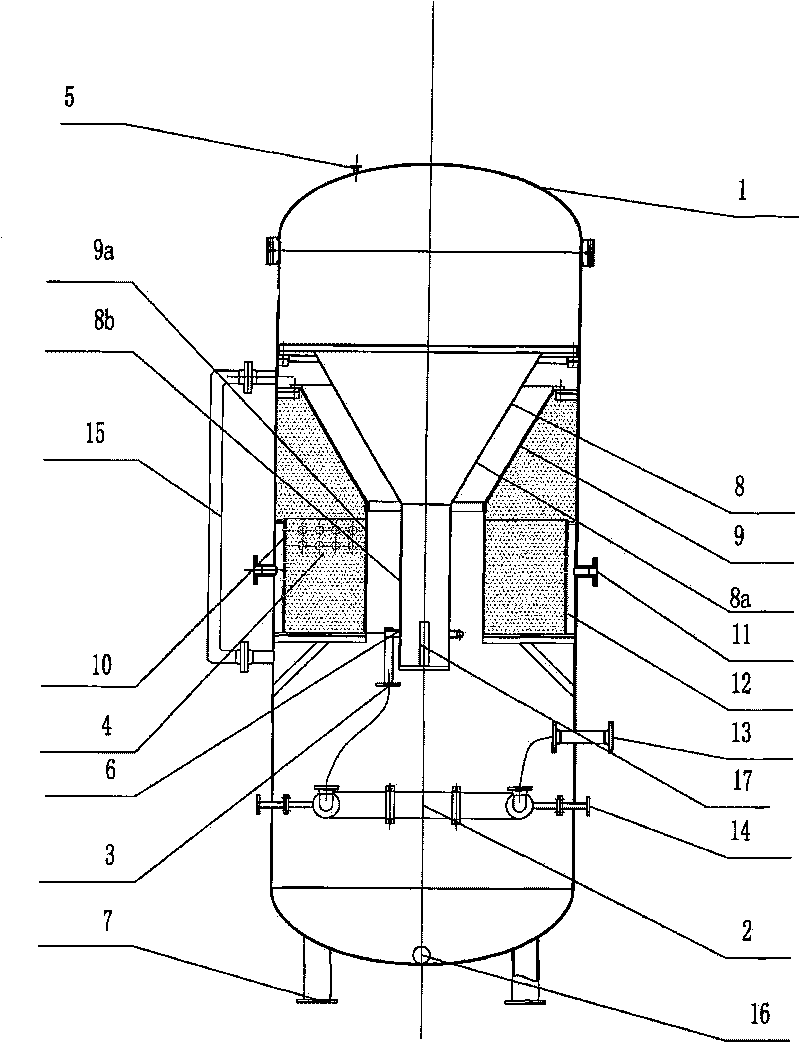

[0031] figure 1 Shown is a settling separation device according to an embodiment of the present invention, which has, for example, an upright cylindrical tank body 1, at least one water inlet 13 and a mixing tank communicating with the water inlet 13 are arranged at the lower part of the tank body 1. The medicine container 2 is provided with two outlets 11 in the middle of the tank body 1 . In addition, a sewage outlet 16 and a mechanism for supporting and fixing the separator such as two legs 7 are provided at the bottom of the tank body 1 . The downstream of described drug mixer 2 is provided with the filter device 4 that links to each other with water outlet 11; The upstream of filter device 4 and the downstream of drug mixer 2 are provided with reactor 8, in order to make structure compact, this reactor 8 and tank The central axis of the body 1 is coaxially arranged. Wherein, the reactor 8 comprises a conical section 8a which expands upward along the vertical axis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com