A corrugated plate separation element

A technology for separating elements and corrugated plates, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., and can solve problems such as inappropriateness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

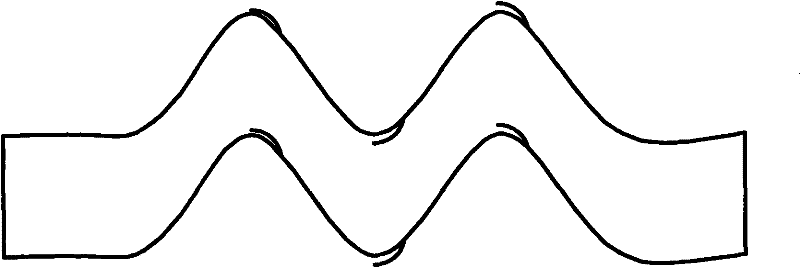

Embodiment Construction

[0024] Hereinafter, the present invention will be described in more detail with examples in conjunction with the accompanying drawings:

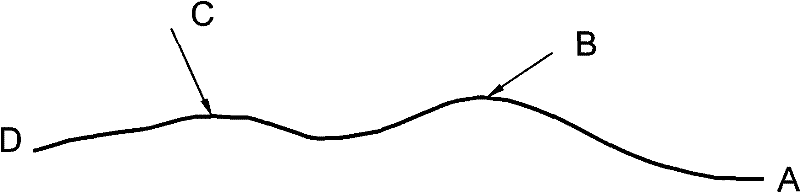

[0025] Such as figure 1 Shown is the designed wave plate separation element form, which is a curved transitional wave plate, including the starting end A, the middle part AD, and the outlet end D. The coordinate system is as figure 1 Shown.

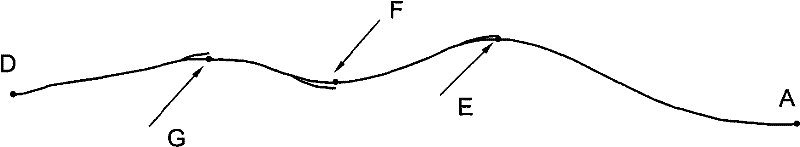

[0026] (1) The profile line of the corrugated plate separating element is divided into three sections, namely AB, BC, and CD, and the three sections are smoothly connected.

[0027] The AB section profile is a change line based on the quadratic parabola, and its profile equation is: y=a+bx+cx 2 In the equation, x and y are variables, and a, b, and c are constants, where a=14.2, b=1254.65, and c=-45382.

[0028] The BC segment type line is a change line based on a sine curve. The type line equation is: y=a·sin[π·(xc) / b], where x and y are variables, and a, b, and c are constants. Where a=7.67, b=0.0008, and c=0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com