Apparatus for molding cooked rice

一种米饭、成形辊的技术,应用在食品的成形、材料成型的压力机、制造工具等方向,能够解决变形或散开等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

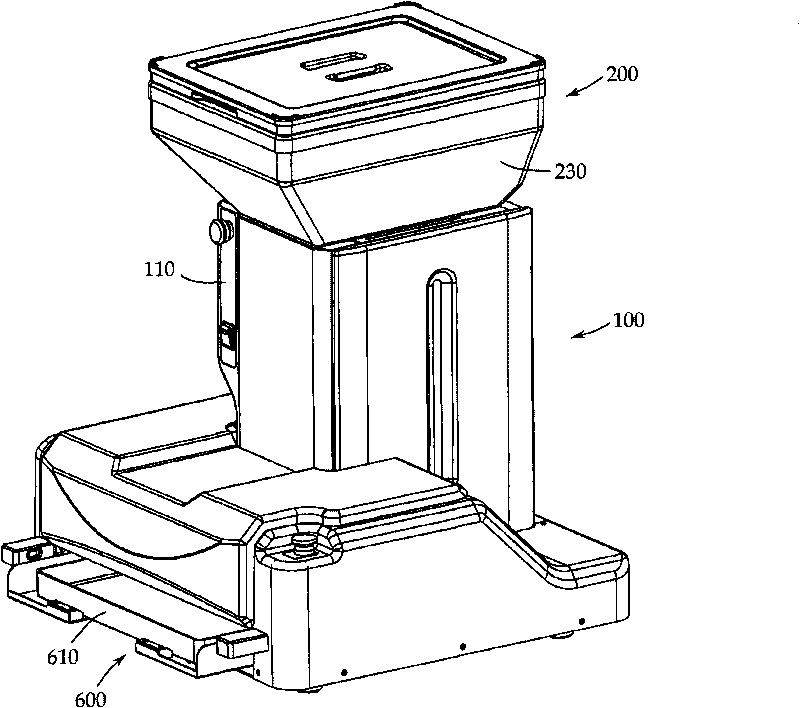

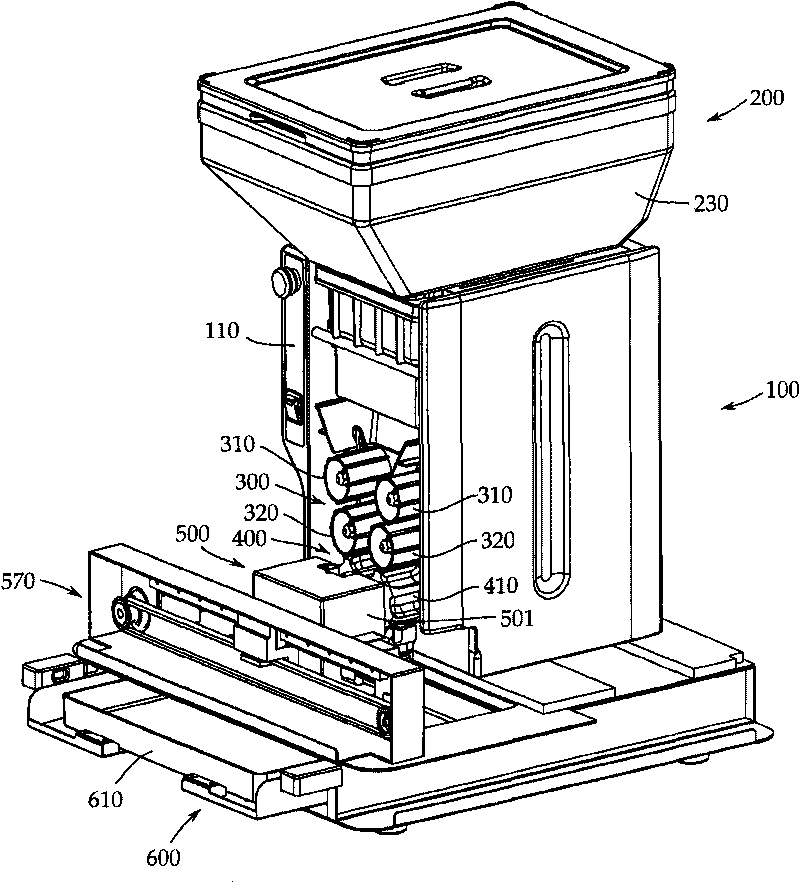

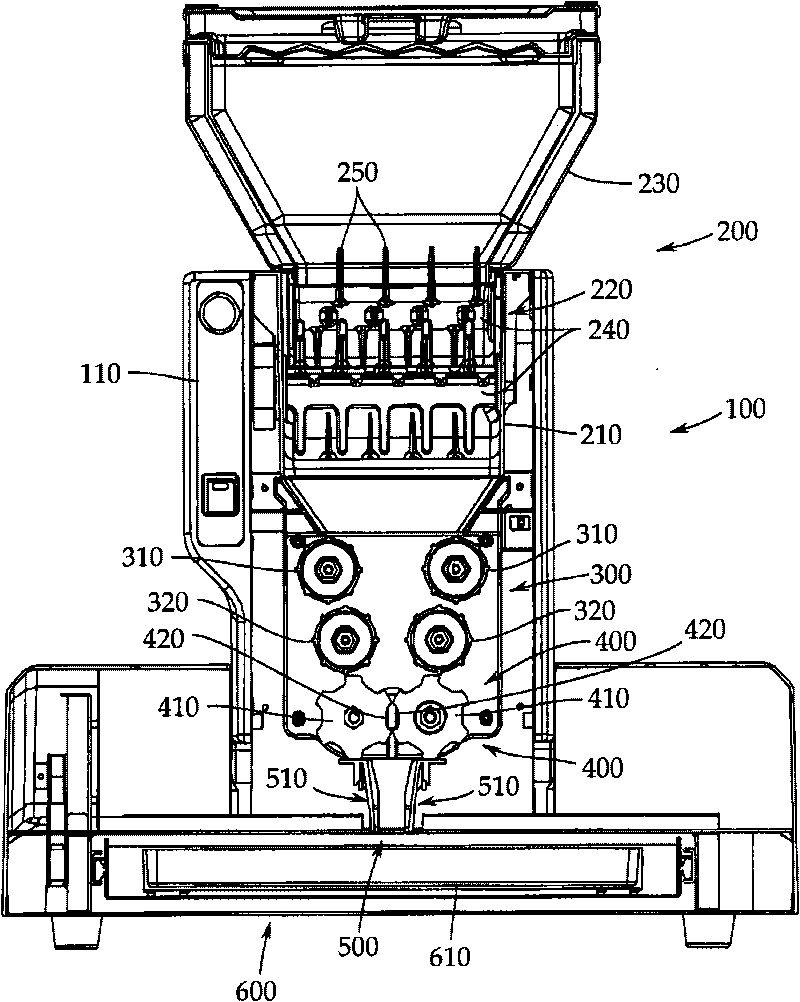

[0026] Next, an embodiment of the present invention will be described with reference to the drawings, but the present invention is not limited thereto. Such as Figure 1 ~ Figure 4 As shown, the rice forming apparatus 100 includes a hopper 200 into which rice (sushi rice) is fed, a compression unit 300 that sends out the sushi rice 10 supplied from the hopper 200 while compressing it, and forms the compressed sushi rice 10 into a predetermined shape. The forming part 400 of the forming part (white rice ball 10: refer to Figure 4 ) transport unit 500 to a predetermined place, and storage unit 600 for temporarily storing rice balls 10 transported from transport unit 500 .

[0027] In addition, in this embodiment, the so-called X-axis direction refers to the width direction of the rice forming apparatus 100 ( image 3 The left and right directions), the Y axis direction refers to the depth direction of the rice forming device 100 ( image 3 vertical direction of the paper). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com