Noise elimination brake for automatic spindle locking mechanism

A spindle and automatic technology, applied in the direction of motor tools, manufacturing tools, portable motor devices, etc., can solve the problems that cannot be incorporated into rotary power tools, etc., and achieve the effect of convenient and repeatable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

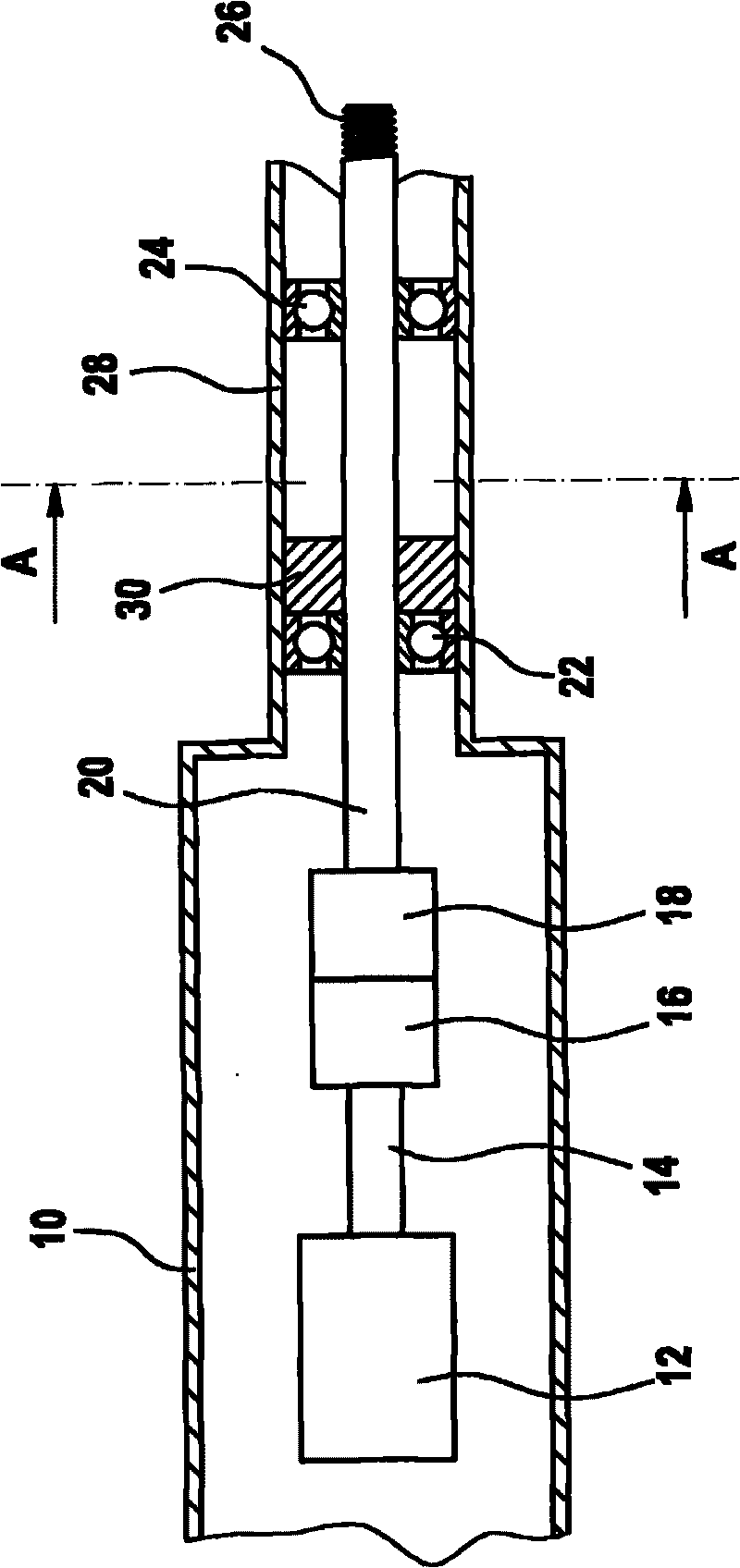

[0017] A part of a rotary power tool (in particular a drill / screwdriver) according to the invention is attached figure 1 is shown schematically. The power source for this tool is usually AC or DC batteries. Located within the rotary power tool housing 10 is a motor 12 and its associated motor shaft 14, which is driven by the power source. Generally, the transmission 16 regulates the speed and torque transmitted by the motor shaft 14 to downstream elements of the powertrain.

[0018] An automatic spindle locking mechanism (ASLM) 18 is located downstream of the transmission 16 . ASLM is well known in the art and the details of how it works will not be described in detail in the present invention. For examples of different ASLMs, the reader is referred instead to US Patent Nos. 6311787 and 2006 / 0131043A1, which are hereby incorporated by reference. As is often the case in the prior art, the transmission 16 is not necessarily separate from the ASLM 18 . That is, it is possibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com