Outer rotor rotary type magnetic fluid travelling wave pump

A magnetic fluid, rotary technology, used in electrical components, electromechanical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

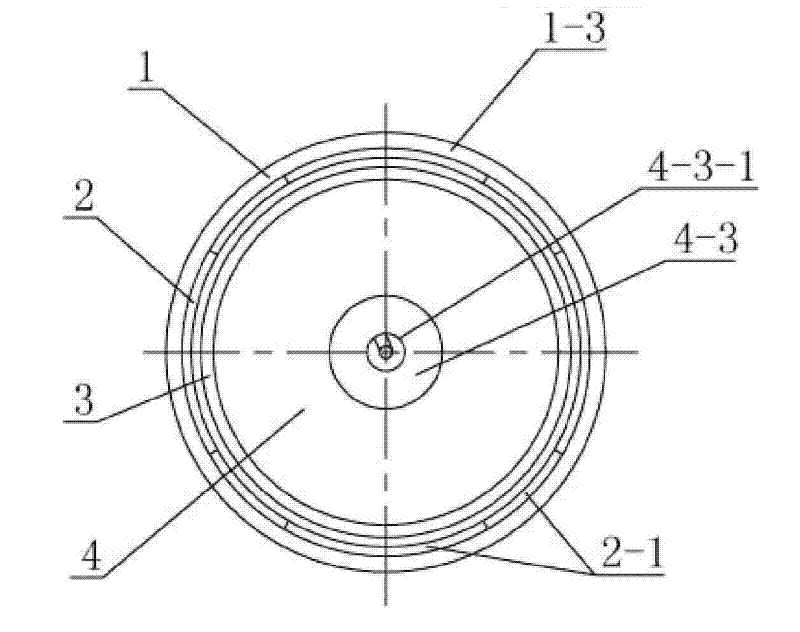

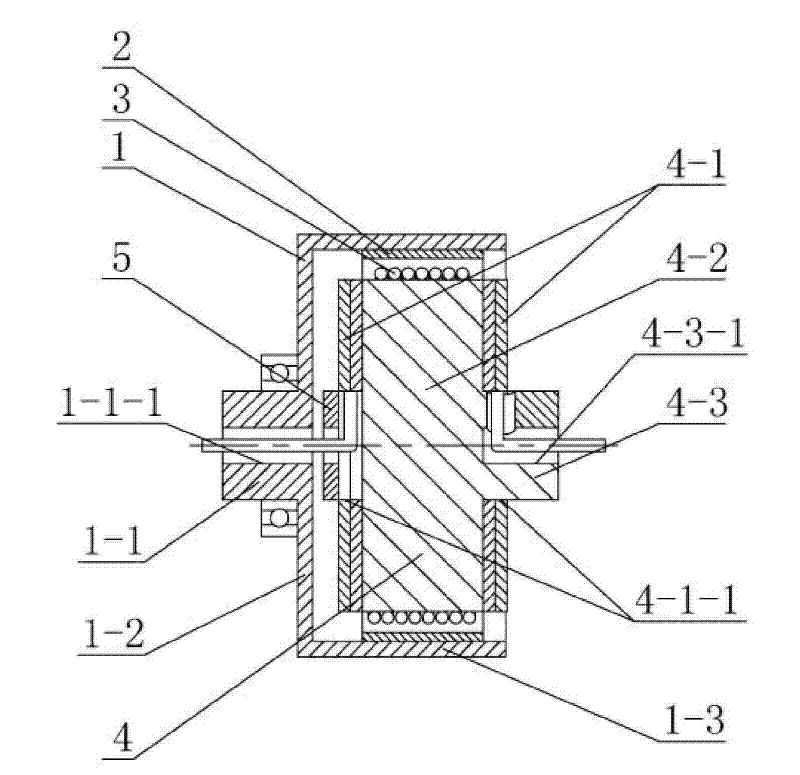

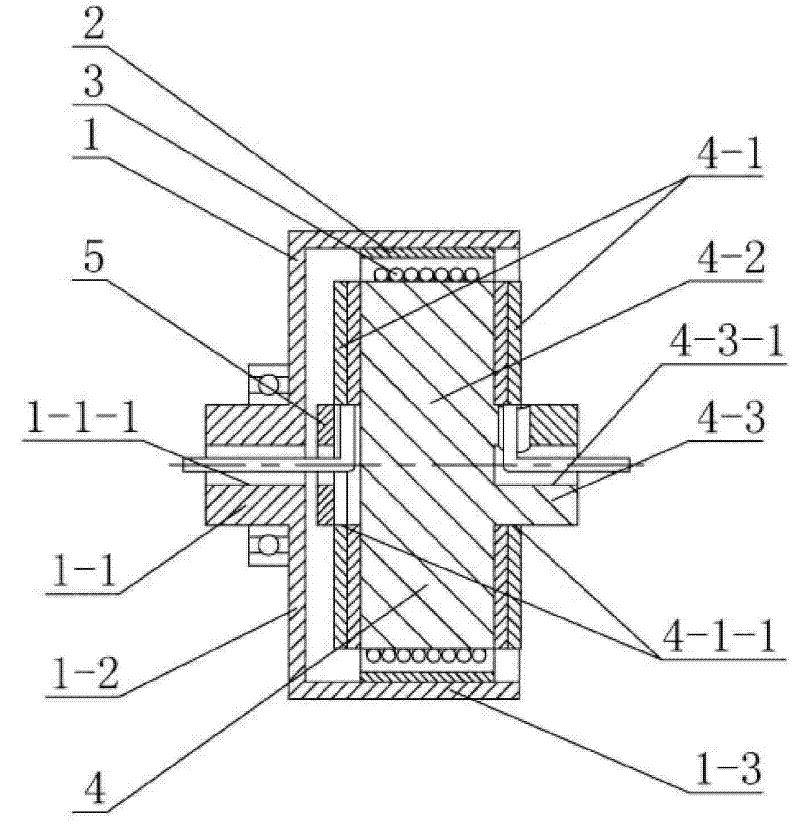

[0007] Specific implementation mode one: as Figure 1~2 As shown, the outer rotor rotating type magnetic fluid traveling wave pump in this embodiment includes a rotor 1, a permanent magnet 2, a coil tube 3 and a stator 4, and the rotor 1 is composed of a first non-magnetically conductive shaft 1-1, a cover plate 1-2 and a cylinder 1-3, one end of the first non-magnetic shaft 1-1 is fixed at the center of the cover 1-2, and the two ends of the cover 1-2 are respectively connected to the cylinder 1- The end of 3 is fixed as a whole, the material of cover plate 1-2 and cylinder 1-3 is magnetic steel, and the cylinder 1-3 is fixedly sleeved on the permanent magnet 2, and the permanent magnet 2 is composed of an even number The permanent magnet monomers 2-1 are magnetized in the axial direction, and the magnetization directions of two adjacent permanent magnet monomers 2-1 are opposite. The stator 4 consists of a magnetically conductive core 4-2, a second nonmagnetically conductive...

specific Embodiment approach 2

[0008] Specific implementation mode two: as figure 2 As shown, the traveling wave pump in this embodiment also includes a fastener 5, which is fixedly sleeved on the coil 3 between the cover plate 1-2 and the magnetic isolation plate 4-1, and the fastener 5 The firmware 5 is made of non-magnetic material. Such setting can play the role of fastening the coil pipe 3 . Other components and connections are the same as those in the first embodiment.

[0009] working principle:

[0010] According to fluid dynamics and electromagnetic field theory, an outer rotor rotating type magnetic fluid traveling wave pump is designed. After the coil 3 is filled with magnetic fluid, the first non-magnetic-conductive shaft 1-1 and the second non-magnetic-conductive shaft 4-3 of the outer rotor rotating type magnetic fluid traveling wave pump are installed on the non-magnetic support. The motor drives the rotor 1 to rotate. Since the rotor 1 is fixedly sleeved on the permanent magnet 2, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com