Ultrasonic flow meter

An ultrasonic and flowmeter technology, which is used in the measurement of flow/mass flow, liquid/fluid solids measurement, and measurement devices, etc. It can solve the problems of large influence of fluid flow path and system failure, and achieve the effect of improving strength and increasing measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

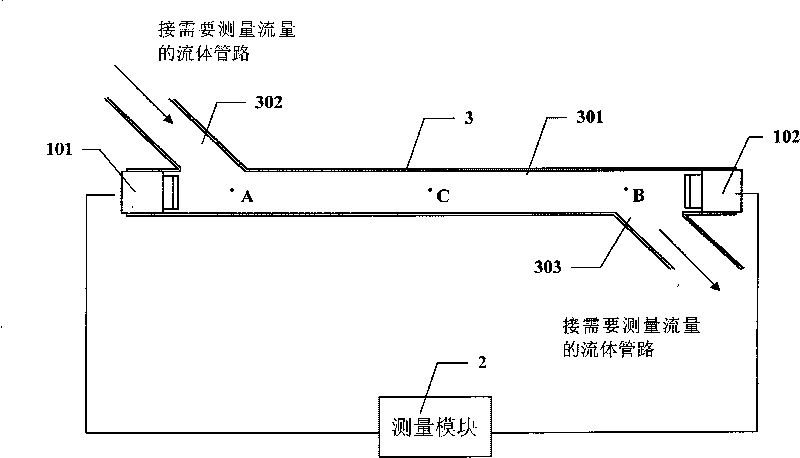

[0026] figure 1 It is a principle diagram of a specific embodiment of the ultrasonic flowmeter of the present invention.

[0027] In this example, if figure 1 As shown, the ultrasonic flowmeter of the present invention includes:

[0028] Two ultrasonic sensors 101 and 102 with the functions of transmitting and receiving ultrasonic waves are used to transmit ultrasonic waves through the fluid to obtain fluid velocity sensing information;

[0029] A measuring module 2 is connected to the two ultrasonic sensors 101 and 102 respectively for control and makes the two ultrasonic sensors 101 and 102 emit ultrasonic waves;

[0030] Measuring pipeline 3, measuring pipeline 3 comprises a section of straight pipe 301, a section of inflow pipe 302 and a section of outflow pipe 303, with the direction of the fluid flowing in the straight pipe 302 as the positive direction of the horizontal coordinate axis, with the inflow pipe 302 and the outflow pipe 303 and the straight The midpoint C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com