Automotive engine hood lock mounting plate

A technology for installing panels and hoods, which is applied to vehicle components, transportation and packaging, and substructures to achieve the effects of avoiding failure, reducing impact force, and reducing the risk of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

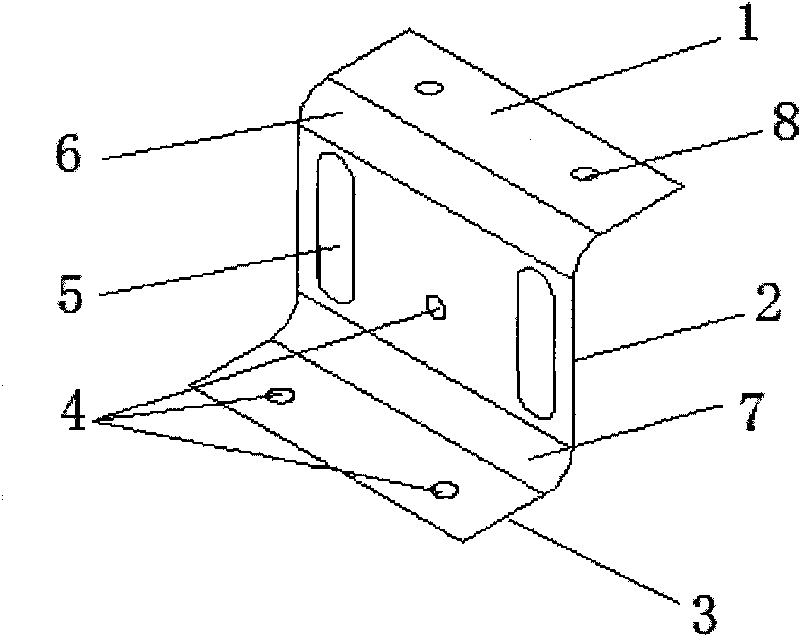

[0015] Such as figure 1 As shown, the automobile hood lock mounting plate of the present embodiment is stamped and formed from a steel plate, and its cross-section is "Z" shape, including a lower mounting surface 3, a side surface 2 and an upper mounting surface 1, and the lower mounting surface 3 and the side surface 2 are separated. There are installation holes 4 for installing the hood lock, two strip-shaped induction holes 5 for inducing the deformation of the side 2 on the side 2, the connection 7 between the side 2 and the lower installation surface 3, and the connection between the side 2 and the upper installation surface 1 The positions 6 are rounded corners, and the upper mounting surface 1 is provided with mounting holes 8 for a fixed hood lock mounting plate.

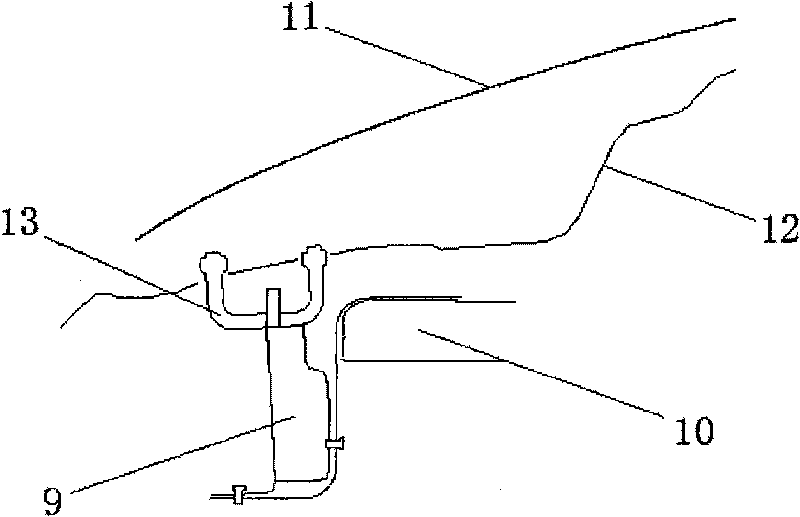

[0016] Such as figure 2 As shown, when in use, the upper mounting surface 1 of the mounting plate is connected with the upper beam 10 of the water tank by bolts, and the hood lock 9 is fixed with the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com