Automotive wiring harness die

A technology for automotive wiring harnesses and moulds, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of wasting labor costs and machinery costs, and insufficient stability, so as to reduce labor costs and machinery costs, improve stability, The effect of reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments

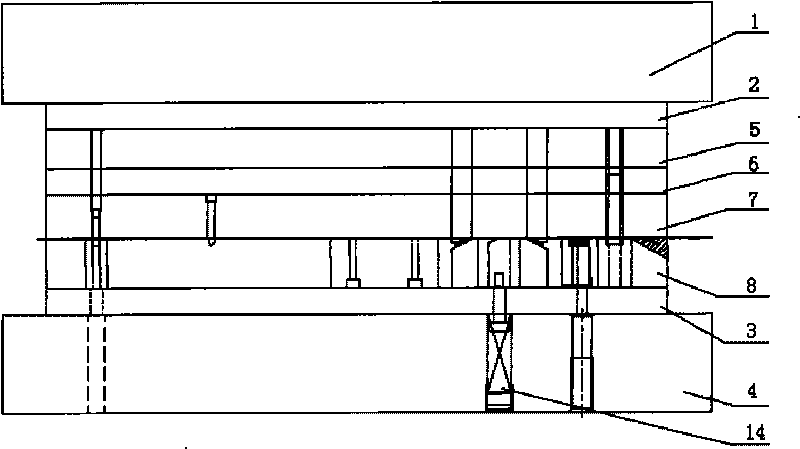

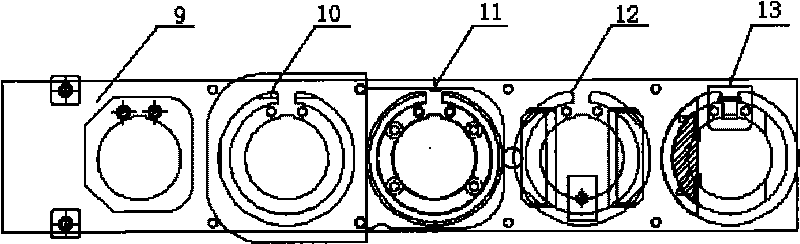

[0014] see Figure 1-Figure 3 , an automobile wiring harness mold, which sequentially includes an upper template 1, an upper backing plate 2, a lower backing plate 3 and a lower template 4, and an upper punching plate 5, a stripping plate, and Material backing plate 6, stripping plate 7 and mold backing plate 8, and stripping plate 7 is provided with guide hole punching die 9, punching punching die 10, chamfering punching die 11, bending punching die 12 and shear blanking punching die 13 .

[0015] The lower template 4 is provided with a bevel mechanism 14 .

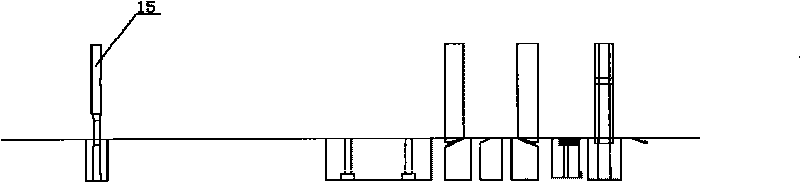

[0016] An upright punch 15 is arranged on the upper punching plate 5 .

[0017] During production, the effect of the upper formwork 1 is to connect the plate bed, the effect of the upper backing plate 2 is to pad the punch 15, and the effect of the upper punch plate 5 is to fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com