Treatment of water with hypobromite solution

A technology of hypobromite and solution, applied in the field of ultrapure water production, can solve problems such as suboptimal procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

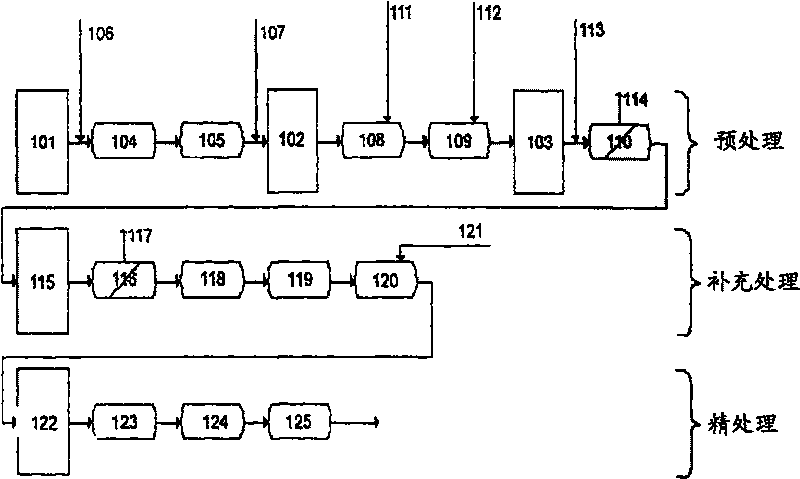

[0059] Figure 1 shows the standard method for ultrapure water production according to the current state of the art. The method is subdivided into three sections, namely, pretreatment, supplementary treatment, and finishing.

[0060] Regarding pre-treatment, the water to be treated is transferred from the reservoir 101 via the filtered water tank 102 to the water tank 103 for deionized water. Between the reservoir 101 and the filtered water tank 102 , the water to be treated flows through a multimedia filter 104 and an activated carbon filter 105 . A flocculant may be added to the water via input line 106 prior to being introduced into the multimedia filter 104 and an antimicrobial agent may be added to the water via input line 107 prior to being introduced into the filtered water tank 102 . A cation exchanger 108 and an anion exchanger 109 are arranged downstream of the filtered water tank 102 . Downstream of the tank 103 for deionized water, the water is introduced into a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com