Permanent-magnet self-starting synchronous motor

A synchronous motor, self-starting technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of permanent magnets not being able to enter, high processing technology requirements, and asymmetric magnetic circuit structure, etc. To achieve the effect of simple structure, large magnetic flux, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

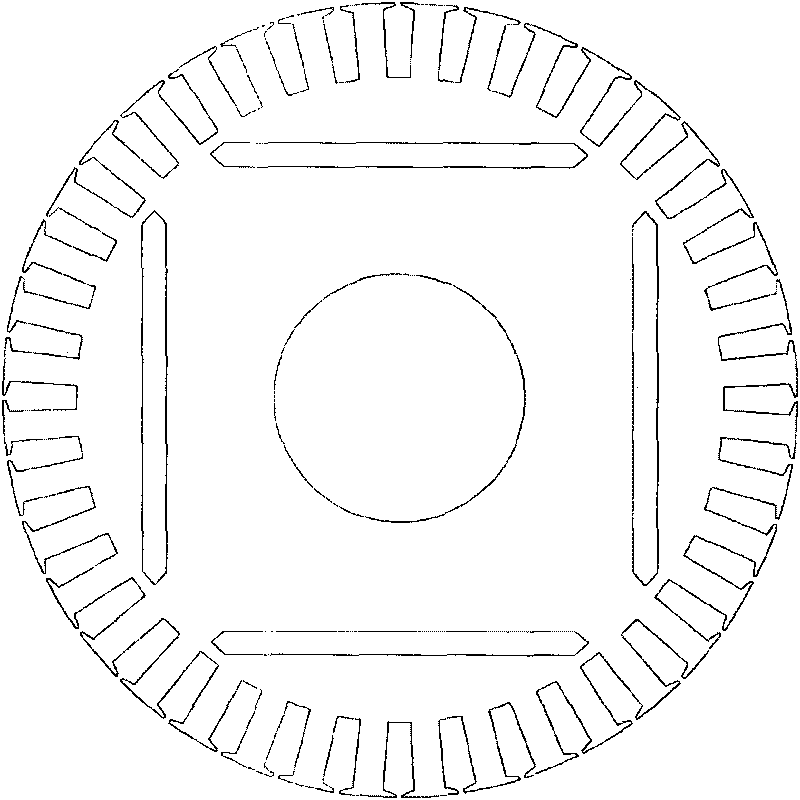

[0038] The permanent magnet self-starting synchronous motor refers to a permanent magnet motor with a starting winding on the rotor, which can start itself and pull in synchronous operation at a certain voltage and frequency. During the starting process, the rotor conductor generates a starting electromagnetic torque. When running synchronously, The rotor conductors do not work. Therefore, the circumference of the rotor is provided with rotor slots for winding the starting winding, and the part between two adjacent rotor slots constitutes rotor teeth, and the rotor slots and rotor teeth are arranged at intervals. Generally, the rotor of a low-power permanent magnet self-starting synchronous motor is made of cast aluminum, and the rotor slot adopts a trapezoidal slot structure. Opposite to the rotor trapezoidal slot is a rotor tooth with a rectangular tooth structure, which is mainly to ensure the uniformity of the magnetic circuit; The rotor of the high-power permanent magnet ...

Embodiment 2

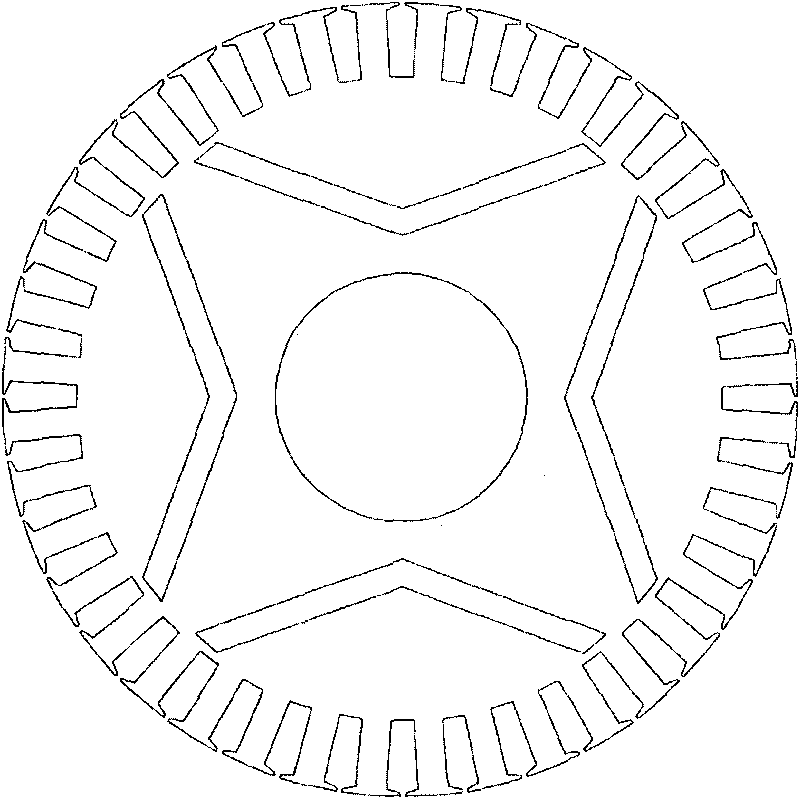

[0052] see Figure 7 , the other structure of this embodiment is the same as that of Embodiment 1, the difference is that: the rotor is divided into 4 pole areas by the centerlines 23, 24, 25, 26 of the rotor slots, and the adjacent pole areas are separated by the center line of the rotor slots. is the boundary, and the centerline of the rotor slot refers to the line passing through the center of the rotor circle and the center of any rotor slot. This embodiment also only takes the rotor with 4 poles as an example, and is not limited to be applicable only to the case of the rotor with 4 poles, and is also applicable to the case of the rotor with 6 poles or 8 poles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com