Wind-power generator blade with multiple C-shaped structure

A technology of wind turbines and blades, which is applied in the field of wind rotor blades, which can solve the problems of increased blade weight and increased wind speed at fan startup, and achieve the effects of reducing tower weight, reducing manufacturing costs, and improving overall strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

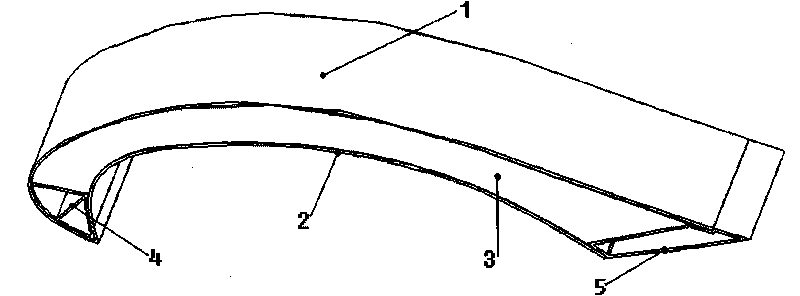

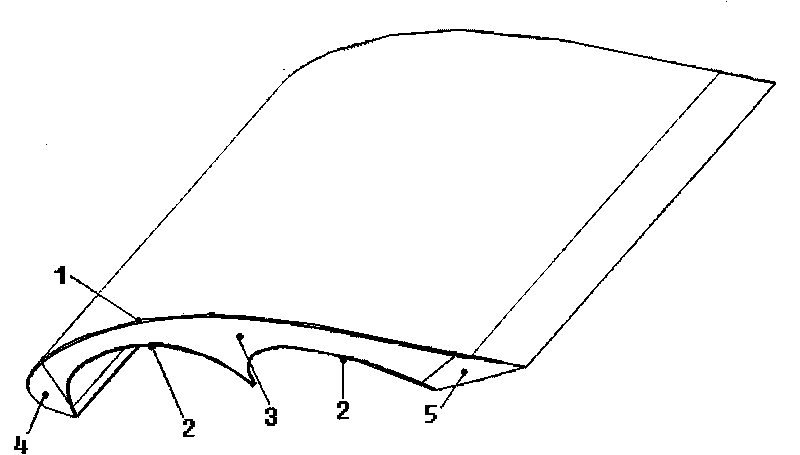

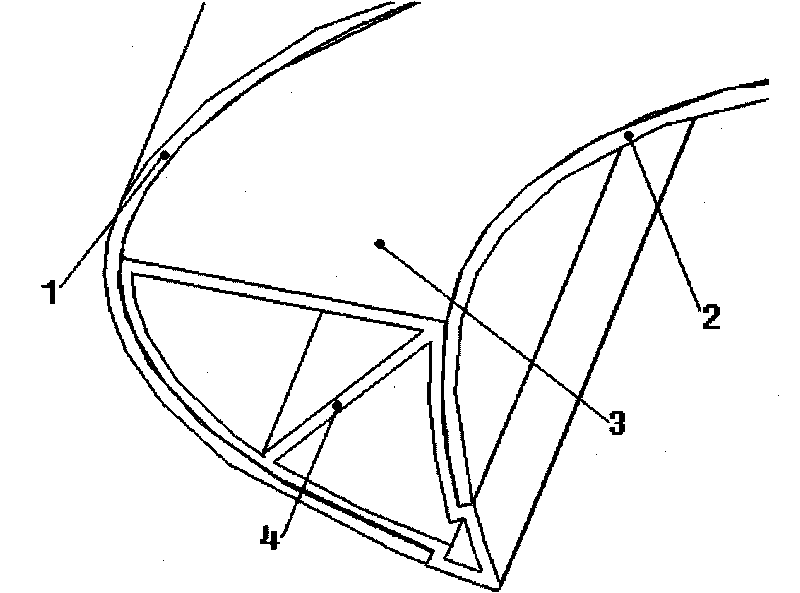

[0017] Vertical axis multiple C-shaped structure wind turbine blades. First, the honeycomb aluminum plate with a thickness of 3-4 mm and a length of 12 m is prepared into the required inner and outer C-shaped shells of the blade according to the design requirements, forming the outer C-shaped plate shell 1 and the inner C-shaped plate shell 2 . Then according to the design requirements, the 3mm aluminum plate is plastically deformed and punched into the designed shape to form the profile support body 3, and the inner C-shaped plate shell 2 and the support body 3 are respectively fixed. Finally, the outer C-shaped plate shell 1 and the inner C-shaped plate shell 2 are connected by using the streamlined splitter head 4 and the flex fin 5 to prepare a wind turbine blade with a vertical axis multi-C-shaped structure. The wind rotor blades prepared by this scheme have good streamline shape and high wind energy conversion efficiency. Under the premise of meeting the mechanical prope...

Embodiment 2

[0019] Horizontal axis multiple C-shaped structure wind turbine blades. First, a metal stainless steel plate with a thickness of 3 to 4mm and a length of 12m is prepared into the required inner and outer C-shaped plate shells of the blade according to the design requirements (decreasing with a gradient of 1:5), forming the outer C-shaped plate shell 1 and the inner plate shell. C-shaped plate shell 2. Then according to the design requirements, the 3mm aluminum plate is plastically deformed and stamped into a designed shape to form a profile support body 3, and the inner C-shaped plate shell 2 and the support body 3 are respectively fixed. Finally, the outer C-shaped plate shell 1 and the inner C-shaped plate shell 2 are connected by the streamlined splitter 4 and the deflector fin 5 to form a single horizontal axis multi-C-shaped wind turbine blade, and the three blades are connected to form a length of 36.5m horizontal axis multiple C-shaped wind turbine blades. The wind ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com