Device for measuring length of transverse cutting machine

A technology of length measuring device and cross-cutting machine, which can be used in measuring devices, metal processing, instruments, etc., and can solve problems such as inaccurate cutting lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

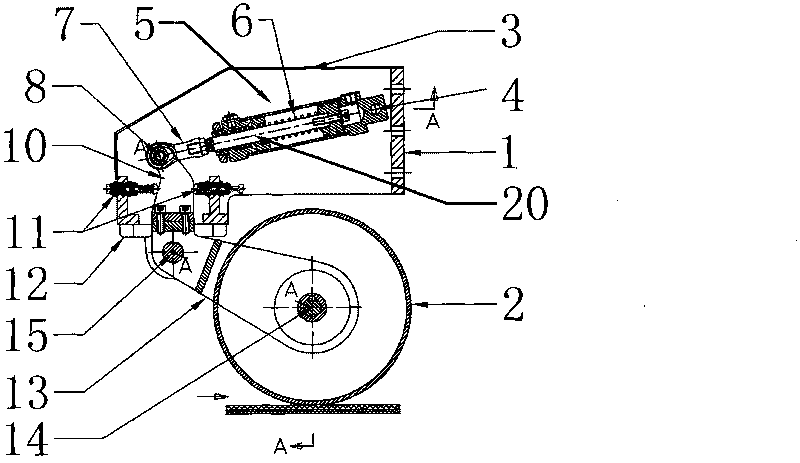

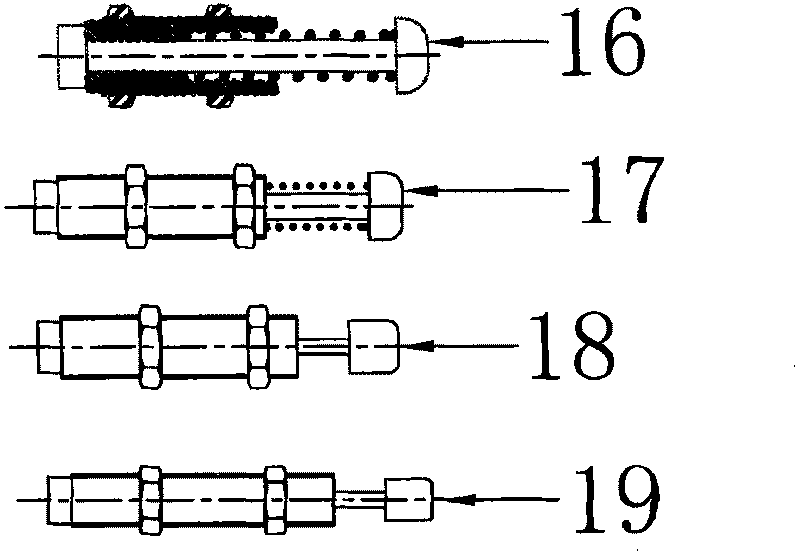

[0012] Attached below figure 1 And attached image 3 To further illustrate the present invention, the preferred embodiment of the present invention is: the cross-cutting machine length measuring device described in this embodiment includes a bracket 1, a length measuring wheel 2, a machine cover 3, a bearing with seat 12, a pendulum shaft 15, Length-measuring wheel base 13, length-measuring wheel shaft 14, encoder 9, cylinder assembly 5, stopper 11, wherein, cylinder assembly 5 and machine cover 3 are installed on the bracket 1 respectively, and cylinder assembly 5 includes cylinder tail pin 4, Cylinder inner spring 6, cylinder joint 7, cylinder joint pin 8, cylinder joint seat 10, wherein, cylinder end pin 4 is installed on the bracket 1, one end of cylinder inner spring 6 is against cylinder end pin 4, and the other end of cylinder inner spring 6 Arrest on the cylinder piston 20, the head of the cylinder piston 20 is hinged with a cylinder joint 7, the cylinder joint 7 is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com