Transmission mechanism of seeder

A transmission mechanism and seeder technology, applied in fertilization devices, applications, agriculture, etc., can solve the problems of affecting the seeding accuracy, non-rotation, and the speed change of the suppression roller blocking the speed change, so as to avoid uneven seeding density, simple structure of the transmission mechanism, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

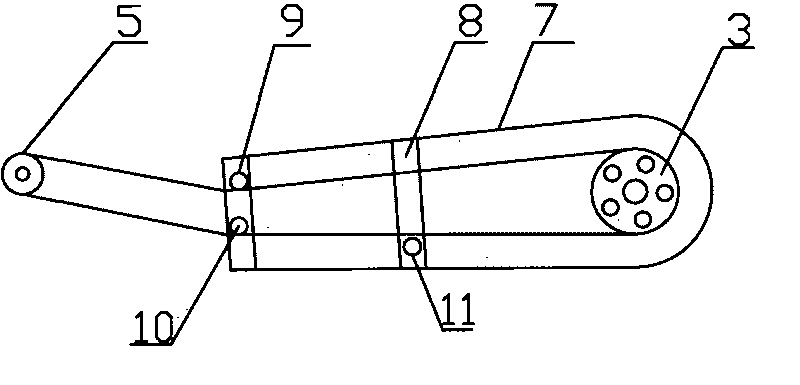

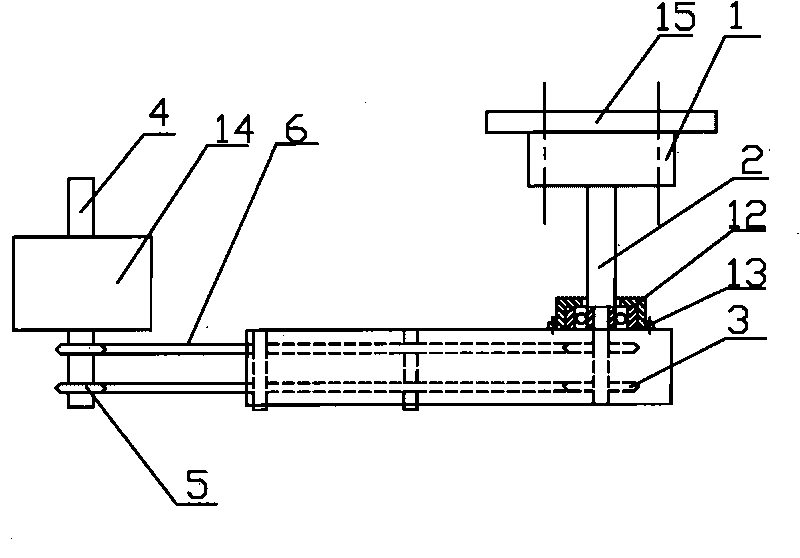

[0018] like figure 1 , figure 2 shown, combined with image 3 . A planter transmission mechanism matched with large and medium-sized tractors, comprising a connection device 1, an input drive shaft 2 fixedly connected to the connection device 1, a first sprocket 3 fixedly connected to the input drive shaft 2, and a seeder main shaft for speed change The output drive shaft 4 connected by box transmission, the second sprocket wheel 5 mounted on the output drive shaft 4 and the chain 6 mounted on the first sprocket wheel 3 and the second sprocket wheel 5 form. The connecting device 1 is fixedly connected with the wheel hoop of the large and medium-sized tractor, which can be a flange, or a shaft, or a shaft sleeve, or a spline; the first sprocket 3, the second sprocket 5 and the chain 6. It consists of multiple pairs; at least one set, that is, a first sprocket 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com