Device for hoisting prefabricated reinforced concrete column on site and walking technology thereof

A technology for reinforced concrete columns and prefabricated columns, which is applied in the directions of transportation and packaging, load suspending elements, and building materials processing, can solve the problems of increasing the use cost of hoisting equipment, high work intensity, and increasing hoisting weight, etc., and achieves economical efficiency. The benefits and comprehensive benefits are remarkable, the vertical process of righting is stable, and the construction productivity is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

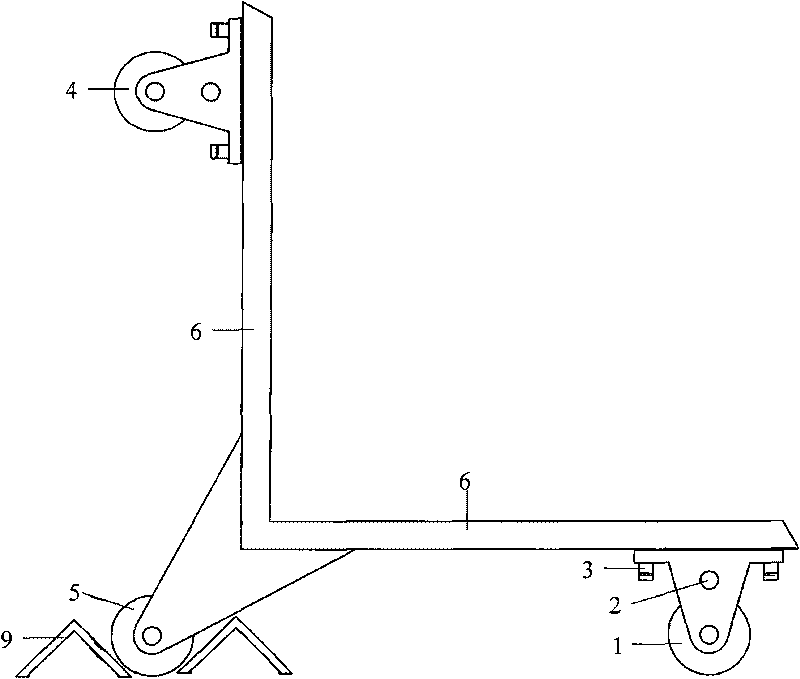

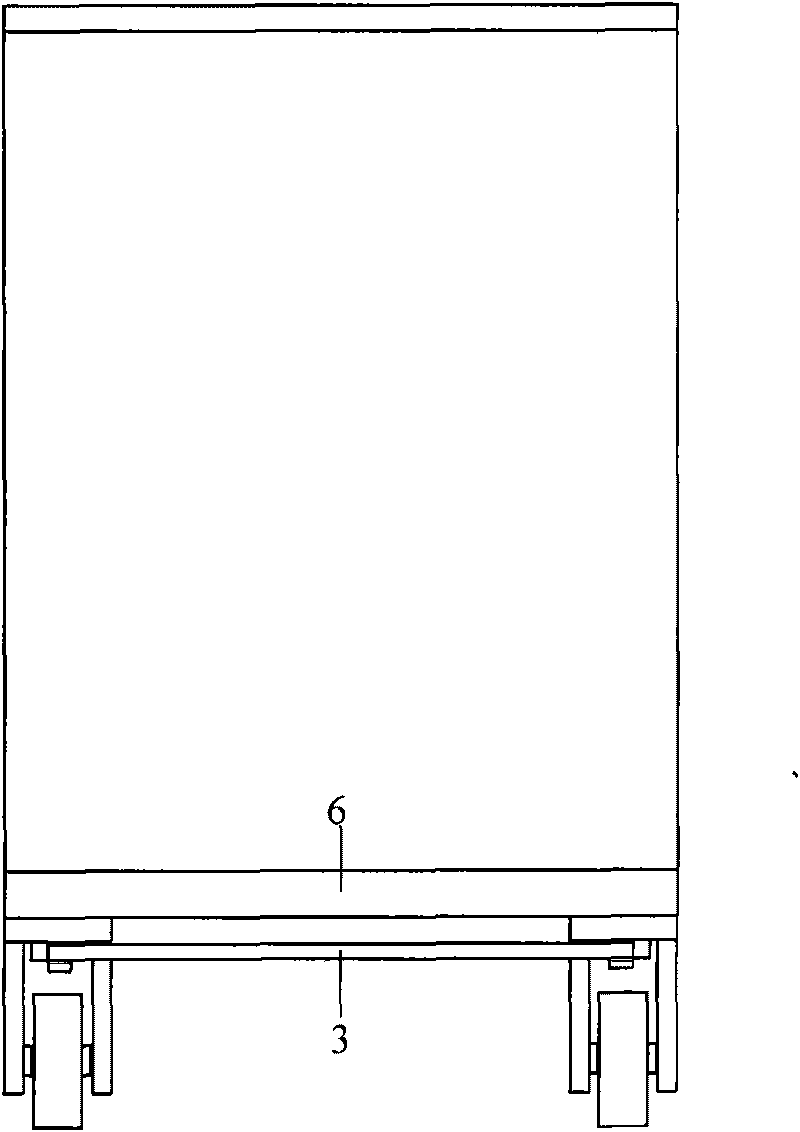

[0023] Depend on Figure 1-4 It can be seen that the steel track slab 10 is firstly laid from the foot position of the prefabricated column 12 to the vicinity of the cup foundation 14 . Insert the horizontal end of the supporting plate 6 of the present invention 11 under the column foot of the prefabricated column 12, and make the column foot support the vertical end of the carriage 6.

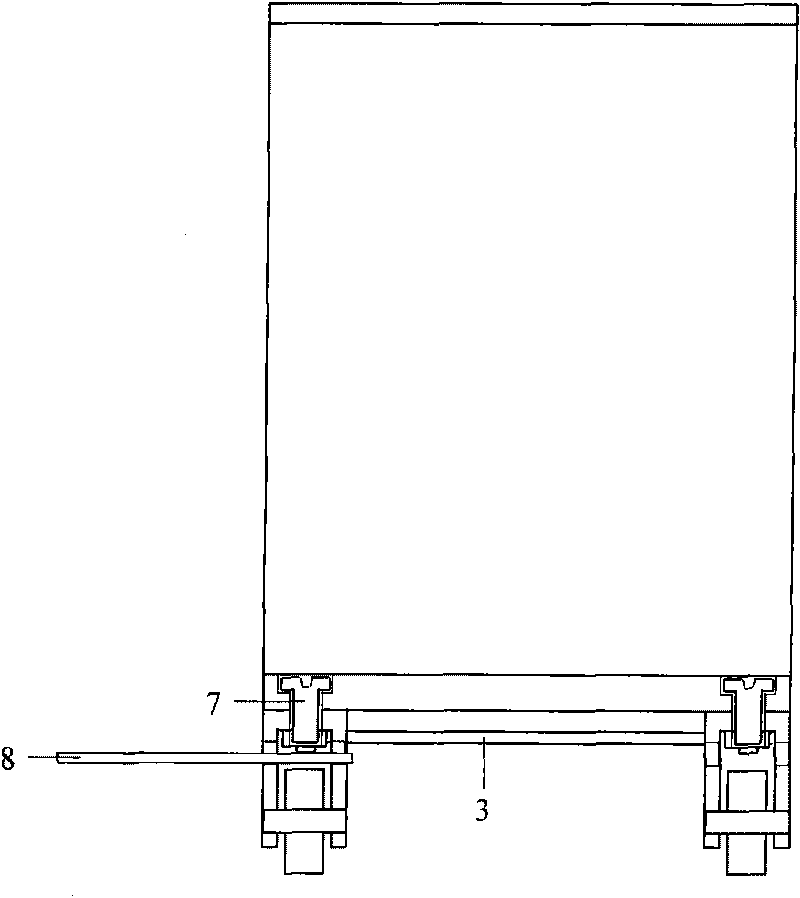

[0024] Bind one end of the wire rope to the other end of the prefabricated column 12 according to the design position, hang the other end of the wire rope on the hook of the crane 13, and then drag the prefabricated column 12 to translate along the predetermined line. When it is necessary to adjust the running direction, insert the steering lever 8 into the jack 2 on the wall of the steering wheel bracket, pull the steering lever 8, and make the rear steering wheel 1 rotate with the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com