Sand seal structure for trolley of desktop forging furnace

A technology for forging heating and heating furnace, which is applied in the field of forging heating furnace and trolley sand sealing structure of desktop forging heating furnace, can solve the problem of short service life of sand seal and trolley steel structure, difficult sand sealing of heating furnace trolley, and maintenance workload. It can reduce the temperature, improve the energy saving effect and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

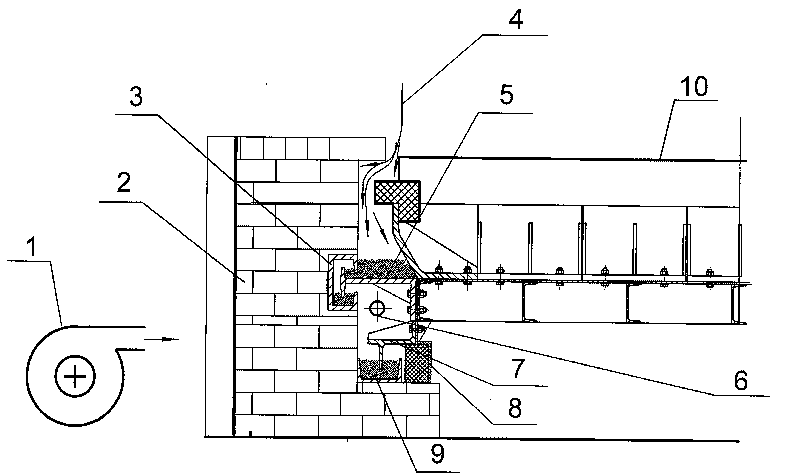

[0024] see figure 1 , figure 1 It is a schematic diagram of the front structure of the table-top forging heating furnace trolley sand-sealed structure of the present invention. Depend on figure 1 It can be seen that the table-top forging heating furnace trolley sand sealing structure of the present invention includes a heating furnace 2, a trolley 10, a high-temperature sand sealing groove 3, a high-temperature sand sealing knife 5, a low-temperature sand sealing groove 9, a low-temperature sand sealing knife 7, and thermal insulation fibers Cotton 8, centrifugal fan 1 and air duct 6, the trolley 10 is set in the heating furnace 2, the high-temperature sand sealing groove 3 is embedded in the furnace wall of the heating furnace 2, and the high-temperature sand sealing knife 5 is made into a horizontal " T"-shaped structure, one end of the high-temperature sand sealing knife 5 is placed in the high-temperature sand sealing groove 3, the other end of the high-temperature sand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com