Water supply device for medium plate cooling after rolling system

A water supply device and cooling system technology, applied in metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve the problem of unstable cooling header spray pressure, production of substandard intermediate products, and inability to provide water normally and other problems, to achieve the effect of better control cooling effect, less investment and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

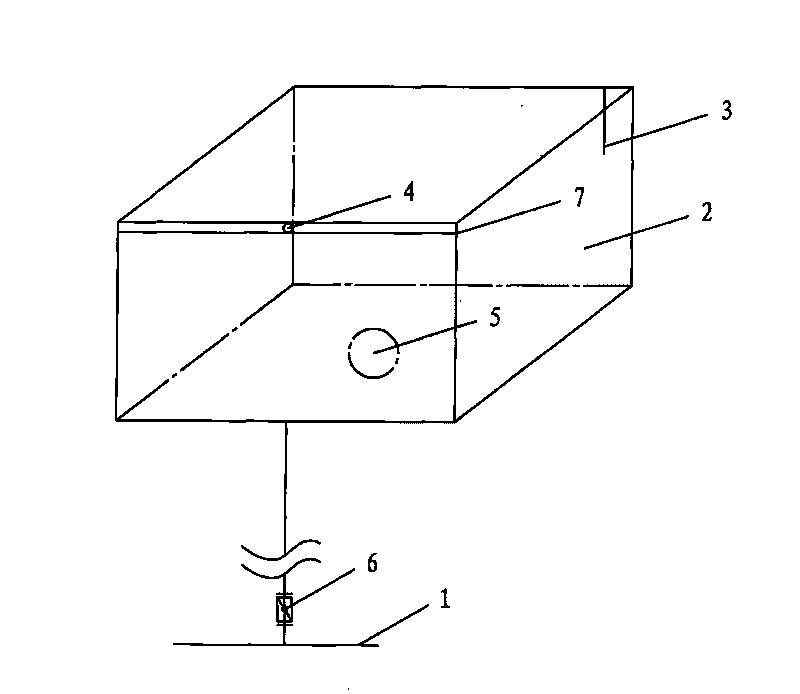

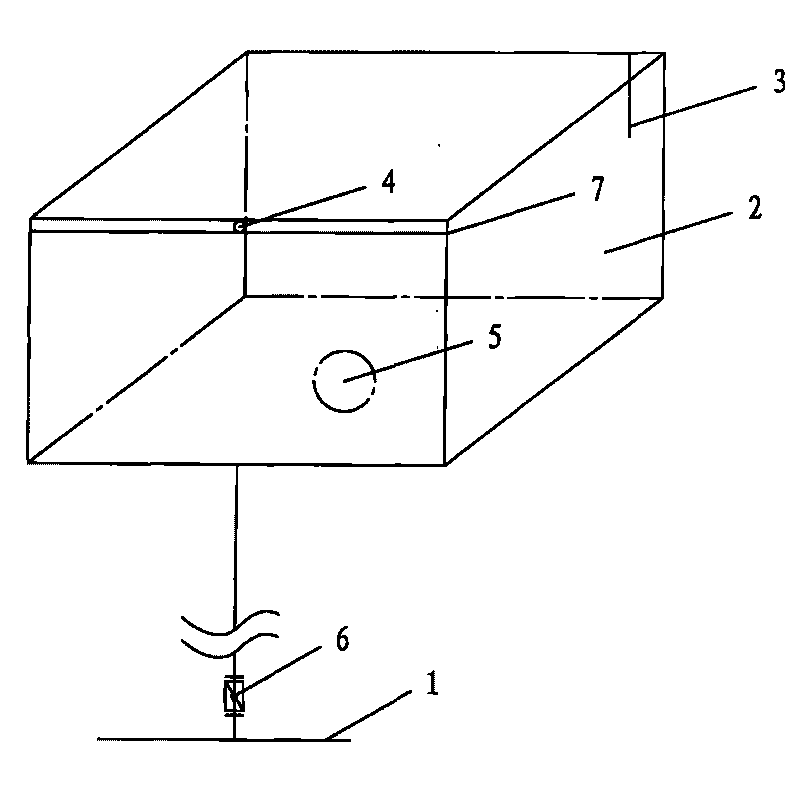

[0009] The water supply device of the post-rolling cooling system of the middle and rear plate of the present invention includes a cooling header 1 and a high-level water tank 2, and the high-level water tank is a concrete structure, which can save cost. The cross-sectional area of the high water tank 2 is 180m 2 , the preset maximum and minimum liquid level difference H is 2.5m. In this way, the pressure difference between the highest liquid level and the lowest liquid level due to the height is only 0.25 bar, while the pressure range of the cooling system is 1 bar to 2 bar. The water supply from the high level water tank can form a stable pressure, and the cross-sectional area of the water tank is sufficient Large, can provide large volume of water instantly.

[0010] In addition, in this embodiment, the water in the high-level water tank is replenished by the cooling pump, and the radar level gauge 3 is used to control the opening and closing of the cooling pump to ens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com