RGB-based method for adjusting white balance of LED backlight

A technology of LED backlight and adjustment method, applied in the direction of light source, electric light source, electric light circuit layout, etc., can solve the problems of difficult to fully reproduce the color of the object, inconsistent luminous brightness, poor white balance, etc., to achieve high precision, improve efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

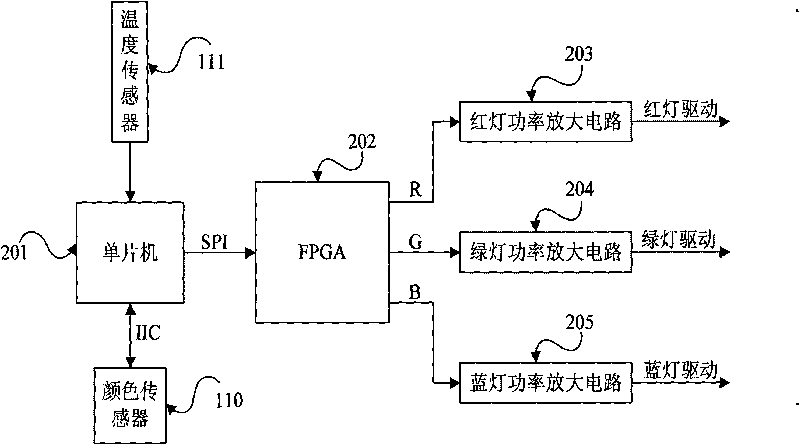

[0037] figure 1Display the composition and layout of components on the backlight board. Each LED lamp contains three different light-emitting units of red, green and blue, and different light-emitting units can be lit individually or simultaneously. Since the luminous efficiency of the LED lamp is related to the temperature, there must be not only the color sensor 110 but also the temperature sensor 111 on the backlight board. One function of the temperature sensor 111 is to feed back temperature data for the main controller to retrieve the standard duty cycle and standard color sensor data at the current brightness level, and the other function is to provide information for the main controller to adjust the power of the backlight panel. When the temperature of the board is too high, the power of the backlight should be reduced (that is, the duty cycle of the drive current of the backlight should be reduced) to protect the backlight and the entire display. The driving of red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com