Magnetic-suspension axial thrust brake for motor screw pump

A screw pump, electric motor technology, applied in the direction of machine/engine, rotary piston type/oscillating piston type pump parts, pump elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

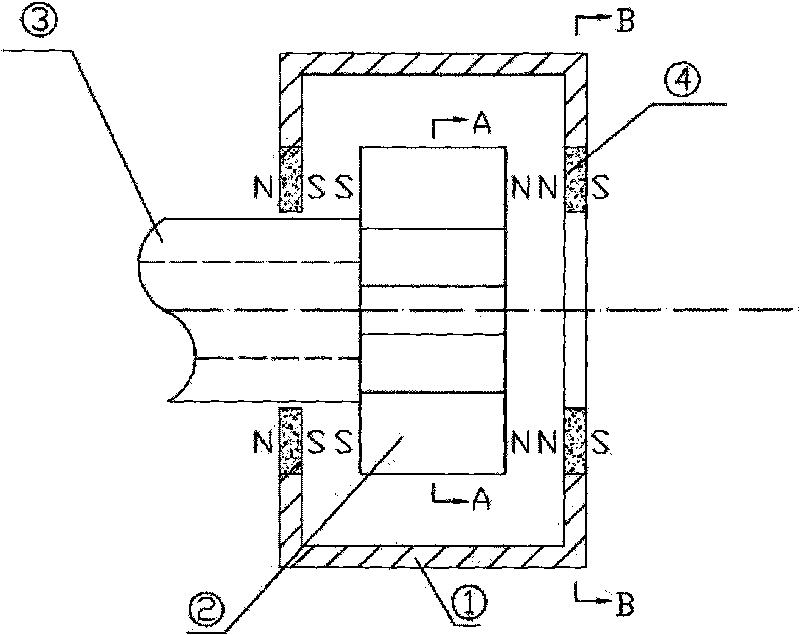

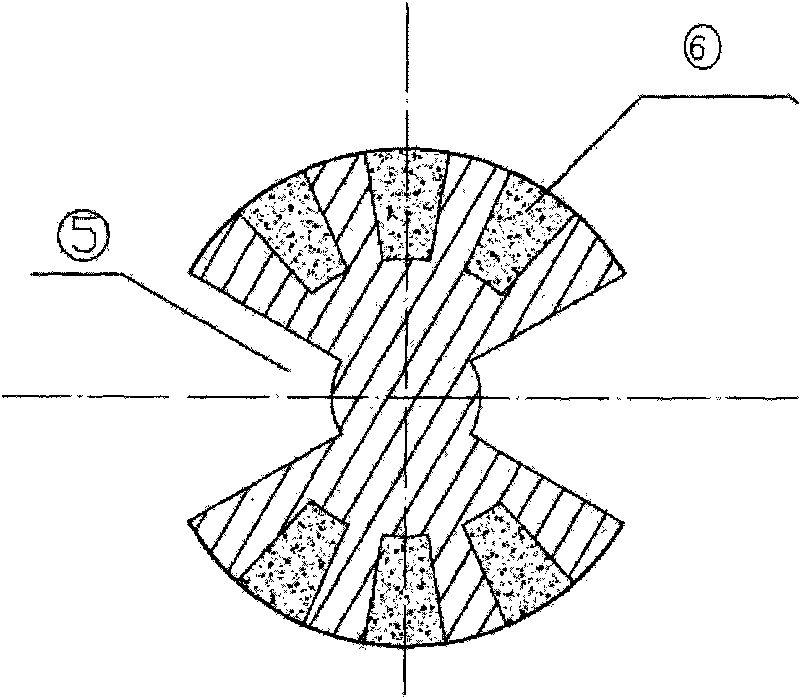

[0009] As shown in the attached figure, ① is the housing, and ② is the extension of the rotor head. In practice, permanent magnets are embedded in both ① and ②. When the magnets are embedded, the S pole of the permanent magnet in ① should be aligned with that in ②. The S poles of the permanent magnets are opposite, and the N poles are opposite to the N poles. And the magnetic induction intensity of the permanent magnets in the pump body located on both sides of ② must be equal, so as to achieve the balance of force and make the rotor levitate, so as to achieve the purpose of axially fixing the rotor .And in order to have enough magnetic force to fix the rotor, and to have an appropriate distance between the rotor and the housing in space, the general suspension air gap is 0.3-3mm (selected according to the specific situation), and the axially protruding distance is taken as 10cm-35cm, the radial extension distance is 5cm-15cm. For example, when the rotor diameter is 20cm, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com