A cold-rolled strip coiler reel

A technology for cold-rolled strip and machine coil, applied in the field of cold-rolled strip coiler reels, can solve the problems of insufficient length, inability to meet, affecting the coiling quality of strips, etc., and improve cylindricity and concentricity. , Improve the dynamic compensation ability, enhance the effect of curl control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

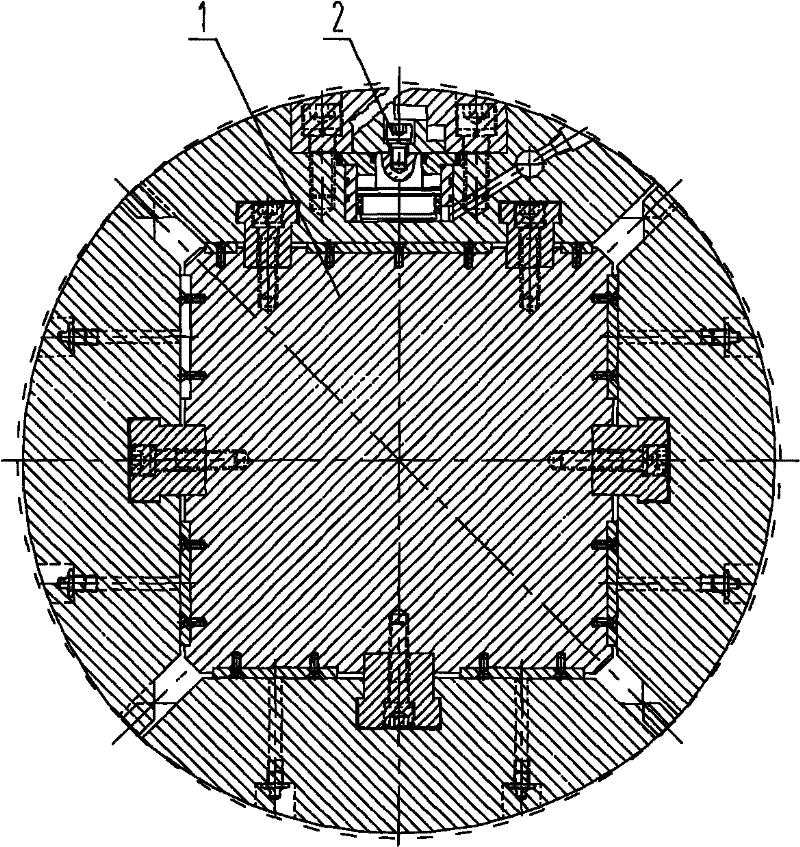

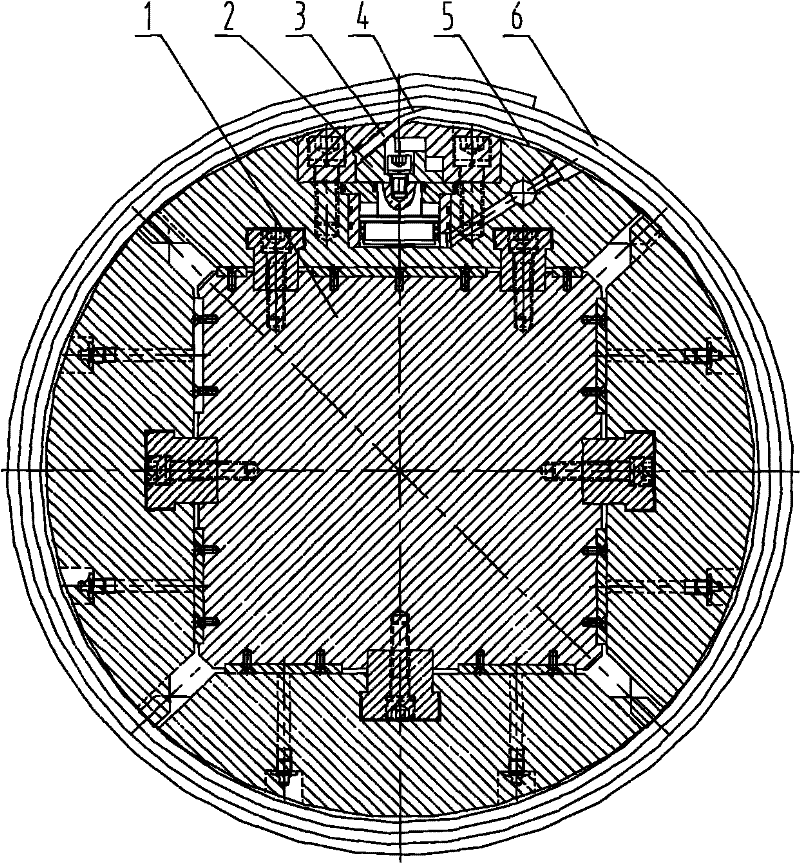

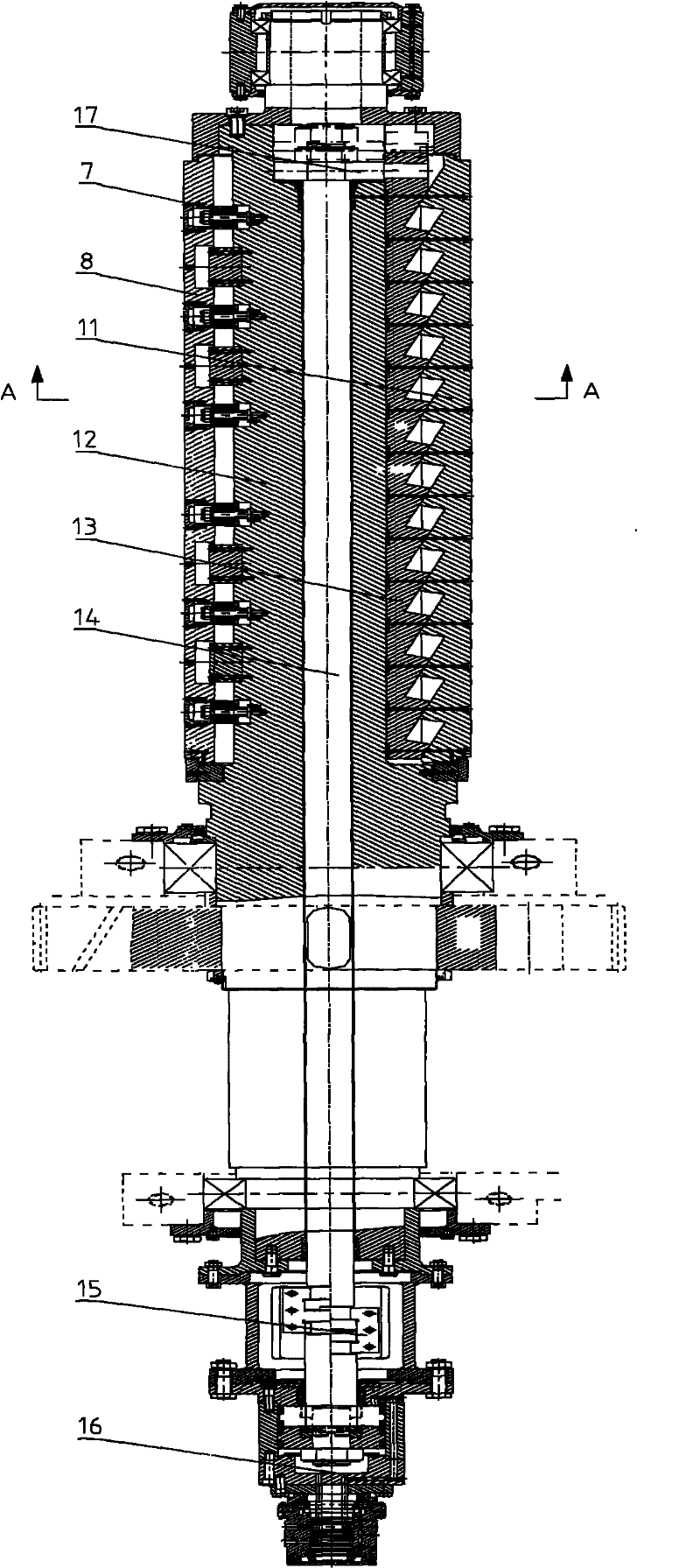

[0020] According to attached image 3 , 4 The present invention is further described as follows:

[0021] The hollow main shaft 12 is the main receiving body of the present invention, supporting the axial wedge 13 and the radial wedge 11 and the like. The axial wedge 13 is placed in the groove of the hollow main shaft 12, the radial wedge 11 is installed on the axial wedge 13; the multi-half sector block 8 is supported on the radial wedge 11, and is connected to the hollow main shaft through the spring body 7 12; the jaw plate 9 is installed in the radial wedge 11 through the elastic body 10; the mandrel 14 is installed in the hollow main shaft 12, one end of which is connected with the axial wedge 13 through the connecting body 17, and the other end is connected The sleeve 15 is connected with the expansion-contraction mechanism 16; the expansion-contraction mechanism 16 is installed on the hollow main shaft 12.

[0022] The expansion and contraction mechanism 16 pushes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com