Method and device for solid phase separation of mixed gas by using hydrate method

A technology that applies hydration and hydration separation. It is applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc. It can solve the problems of poor separation effect, hindering the promotion of hydrate separation technology, and difficult continuous separation, so as to reduce the energy consumption of the device. , Improve the hydration separation efficiency, the effect of high hydration separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment is an immobilized hydration separation process for desulfurization and decarbonization of natural gas.

[0039] The gas mixture consists of CO 2 20%, H 2 S concentration is 3500ppm, methane is 65%, and other hydrocarbons are 15%. Natural gas is exported from a natural gas well with a pressure of 15MPa and a temperature of 125°C.

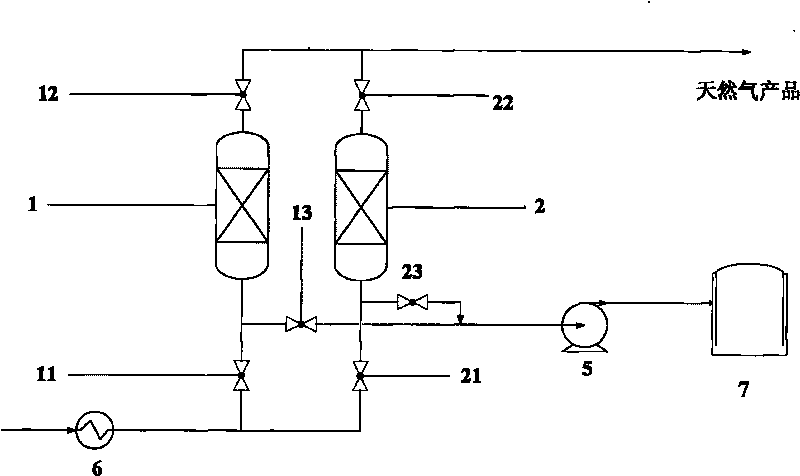

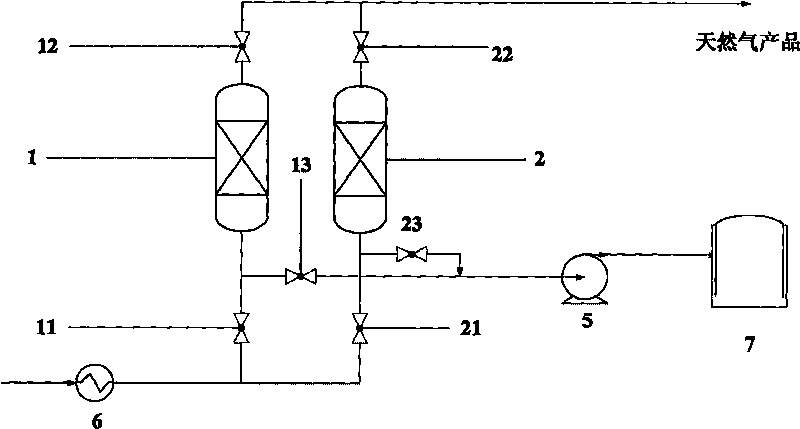

[0040] The device of the present invention comprises an immobilized hydration separation tower 1, an immobilized hydration separation tower 2, a vacuum pump 5, a cooler 6 and a storage tank 7; the cooler 6 is respectively connected to the inlet of each immobilized hydration separation tower through pipelines, The outlet of the hydration separation tower is connected with the storage tank 7 and the vacuum pump 5 through pipelines.

[0041] The trays of the immobilized hydration separation tower 1 are coated with polyacrylamide (polymer hydrogel) with a water content of 65%wt, and tetrabutylammonium bromide is used as a high-eff...

Embodiment 2

[0045] This embodiment is a coal-fired power plant tail gas CO 2 Captured immobilized hydration separation process.

[0046] Raw gas composition is N 2 (71%) and CO 2 (29%) mixed gas. Four immobilized hydration separation towers are connected in parallel, and the polymer hydrogel coated on the trays is polyacrylamide with a water content of 85%wt, and tetrabutylammonium bromide (TBAB) is used as a high-efficiency hydrate accelerator.

[0047] The device of the present invention comprises an immobilized hydration separation tower 1, an immobilized hydration separation tower 2, an immobilized hydration separation tower 3, an immobilized hydration separation tower 4, a vacuum pump 5, a cooler 6 and a storage tank 7; It is connected with the inlet of each immobilized hydration separation tower, and the outlet of the immobilized hydration separation tower is connected with the storage tank 7 and the vacuum pump 5 through pipelines.

[0048] After the mixed gas is cooled to 20°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com