Battery installation structure for electric vehicles

An installation structure and electric vehicle technology, applied in the direction of electric power devices, power devices, structural parts, etc., can solve the problems of installing and disassembling batteries without too much consideration, hindering the large-scale promotion and application of electric vehicles, and limiting the use range of electric vehicles, etc. problems, to achieve the effect of reducing operating workload, improving system reliability, and fixing and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

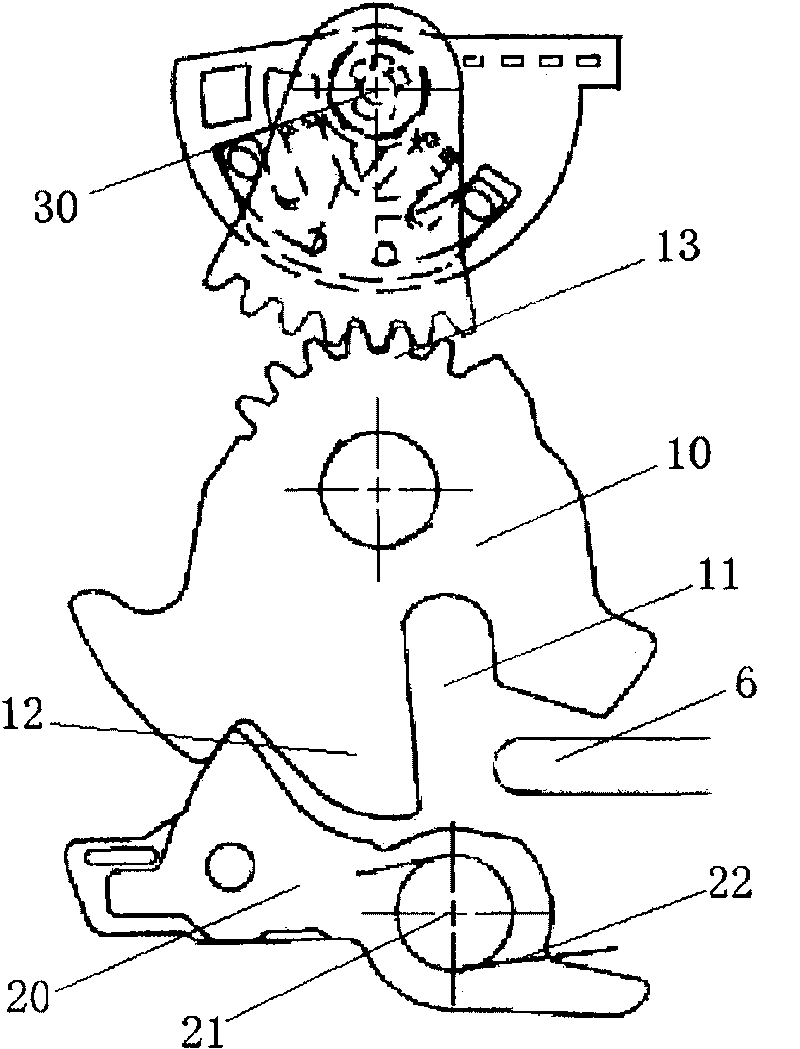

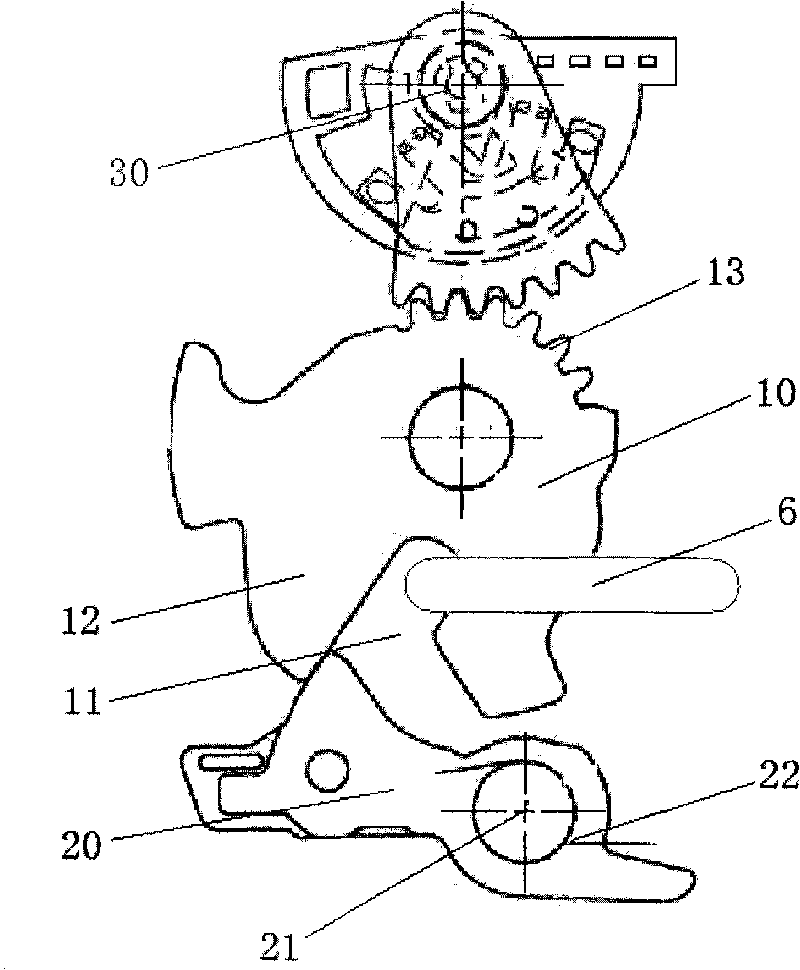

[0020] The battery mounting structure of the electric vehicle of the present embodiment includes a battery pack for accommodating the battery pack 1 and a locking mechanism for fixing the battery pack, such as figure 1 As shown, the top surface of the battery pack is provided with a power interface 7 and a data interface 8, and the inside of the battery pack is provided with a battery signal acquisition module 2 and a battery management module 3 connected to the data interface 8, and the four corners of the battery pack are provided with The direction of the lock is perpendicular to the lock 6 on the bottom of the battery pack, and there are air inlets 4 and air outlets 5 for cooling air on both sides of the battery pack; figure 2 , 3 As shown, the locking mechanism includes a rotatable fork latch 10 and a stop claw 20 for locking the fork latch. The latch table 12 matched with the stop claw, the side of the latch table 12 away from the fork 11 is an arc surface, the stop cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com