Fully automatic anchor cable blanking machine

A blanking machine and fully automatic technology, which is applied in the direction of metal sawing equipment, sawing machine devices, sawing machine accessories, etc., can solve the problems of workers' own safety and production safety, difficulty in operation, and low work efficiency. Reliable performance, protection of the external environment, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

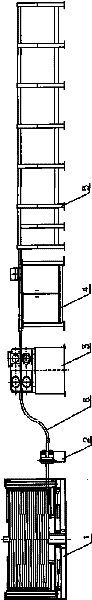

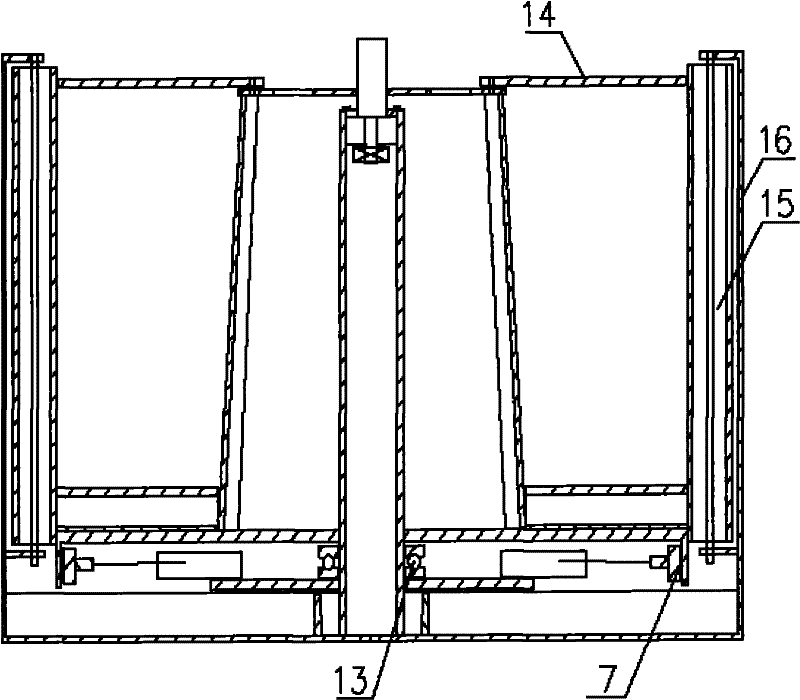

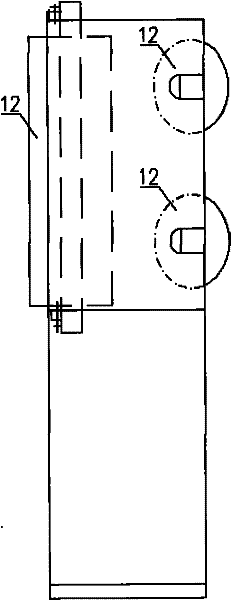

[0022] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a pay-off reel 1, a tractor 3, a sawing machine 4, and an unloading frame 5 that are connected to the electronically controlled air control system and connected in sequence through a steel strand 6. There is a guide wheel set 2 composed of four supporting rollers 12 arranged side by side and interlaced horizontally and vertically. The steel strand 6 passes through the guide wheel set 2; 13 and a braking device 7 is set, the top is provided with a bulletproof gland 14, the periphery is provided with a vertical roller 15 and a baffle plate 16, and a lock is installed at the tail end of the steel strand 6; The guide groove 8, the guide groove 8 communicates with the guide block in the pressing device 9, the cutting saw 11 controlled by the lifting of the cylinder 10 is installed in the sawing machine 4 located at the lower end of the pressing device 9, the limit switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com