Electromagnetic flowmeter for non-full pipe flow measurement

An electromagnetic flowmeter and flow measurement technology, which is applied in the application of electromagnetic flowmeters to detect fluid flow, measure flow/mass flow, liquid/fluid solid measurement, etc., can solve problems such as flow pattern sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The patent embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

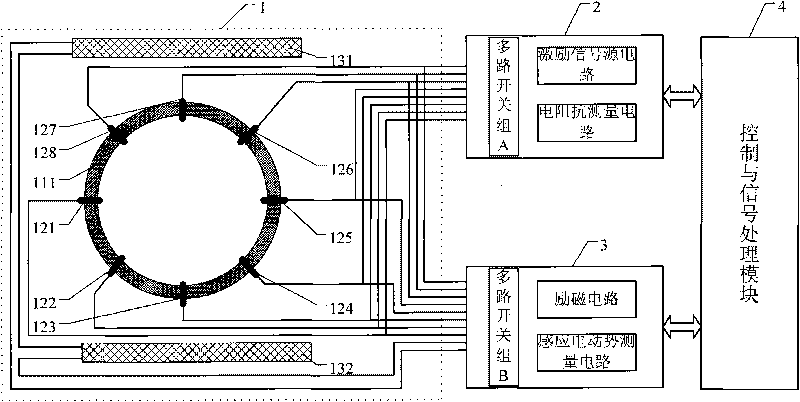

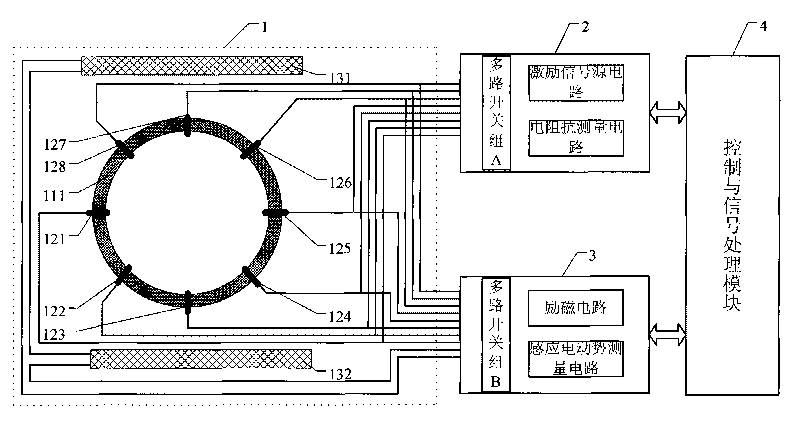

[0015] attached figure 1 It is a structural schematic diagram of an electromagnetic flowmeter that can be used for the measurement of partial pipe flow. The electromagnetic flow sensor 1 includes a measuring tube 111, a plurality of electrodes 121 to 128, and excitation coils 131 and 132; the measuring tube is a circular tube structure, and its manufacturing material is an insulating material; the electrodes 121 to 128 are in the form of point electrodes, etc. The spacing is embedded on the inner wall of the same section of the measuring tube 1, wherein the connecting line of the electrode 121 and the electrode 125 is perpendicular to the connecting line of the coil center and parallel to the horizontal plane; On both sides of the coil, the center line of the coil passes through the center of the circle and is connected in series. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com