Distribution system of magnetic supports in vacuum glass

A vacuum glass and support technology, applied in glass forming, glass remolding, glass manufacturing equipment and other directions, can solve the problems of high error rate and low efficiency, achieve high deployment efficiency, reduce manufacturing costs, and deploy The effect of low error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

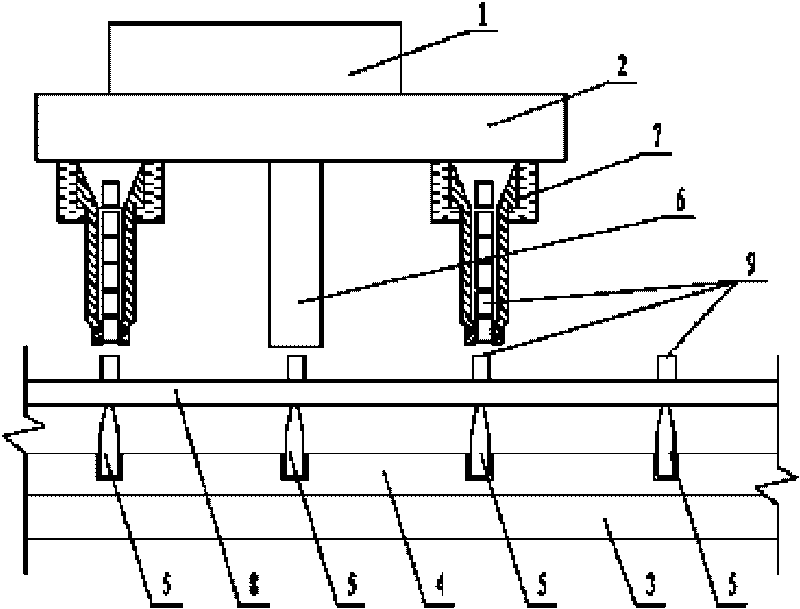

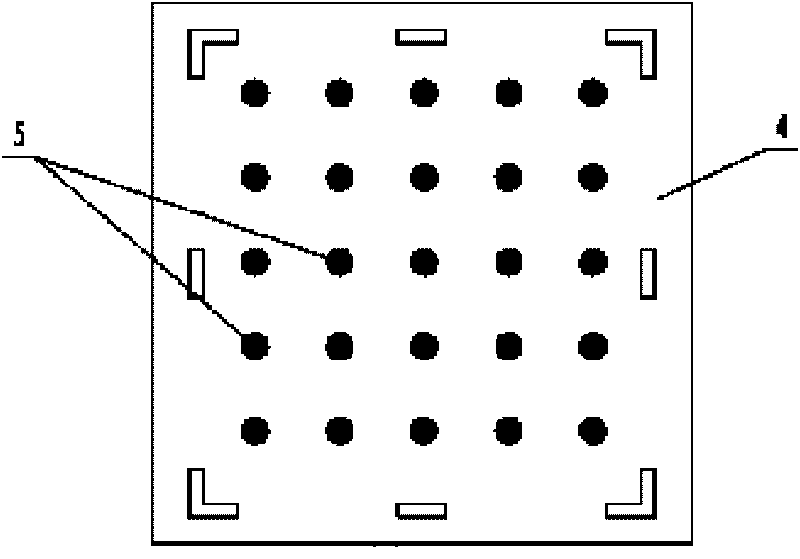

[0008] Specific implementation mode one: combine Figure 1 ~ Figure 2 Describe this embodiment, the system for laying magnetic supports in vacuum glass in this embodiment is composed of a stepping drive motor 1, a movable base 2, a cloth inspection assembly, a placement table 3, an electromagnetic generator 4 and a plurality of magnets 5 Composition, the cloth inspection component package is composed of a photoelectric detection head 6 and two deployment pens 7, an electromagnetic generator 4 is installed on the upper end surface of the deployment platform 3, and the plurality of magnets 5 are evenly arranged on the electromagnetic On the generator 4, the cloth inspection assembly is placed above a plurality of magnets 5, the photoelectric detection head 6 and two deployment pens 7 are installed on the movable base 2, and the photoelectric detection head 6 is located on two Between the placement pens 7, the distance between the photoelectric detection head 6 and each placement...

specific Embodiment approach 2

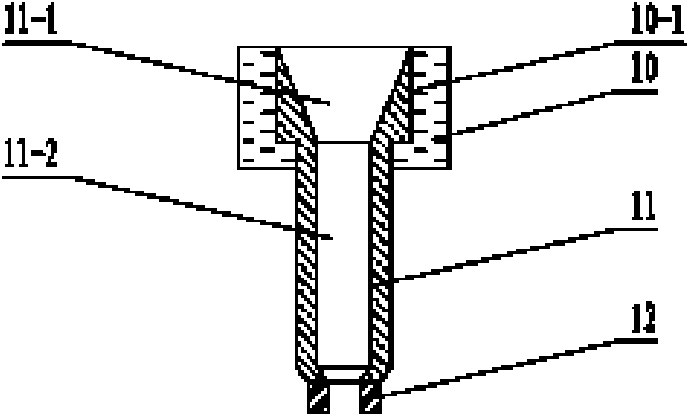

[0010] Specific implementation mode two: combination image 3 and Figure 4 Describe this embodiment, the deployment pen 7 of this embodiment is composed of a base body 10, a housing 11 and two magnetic clamping plates 12, the upper end surface of the base body 10 is provided with a shoulder hole 10-1, and the The upper end of the housing 11 is installed in the shoulder hole 10-1, the upper part of the inner cavity of the housing 11 is a tapered hole 11-1, and the lower part of the inner cavity of the housing 11 is an elongated hole 11-2, so The tapered hole 11-1 is the preparation space for the magnetic support, and the elongated hole 11-2 is the falling space for the magnetic support. The two magnetic clamps 12 are correspondingly arranged on the lower end surface of the housing 11. The distance between the clamping plates 12 is equal to the diameter of the magnetic support 9, and the space between the two magnetic clamping plates 12 is the clamping space of the magnetic su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com