Multi-functional intelligentized log sawing machine

A multi-functional, log technology, applied in the direction of circular saws, sawing components, sawing equipment, etc., can solve the problems of large safety hazards, large amount of consumables, and large amount of chip removal, etc., to prevent reflections from hurting people, and to achieve safety features High, highly automated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

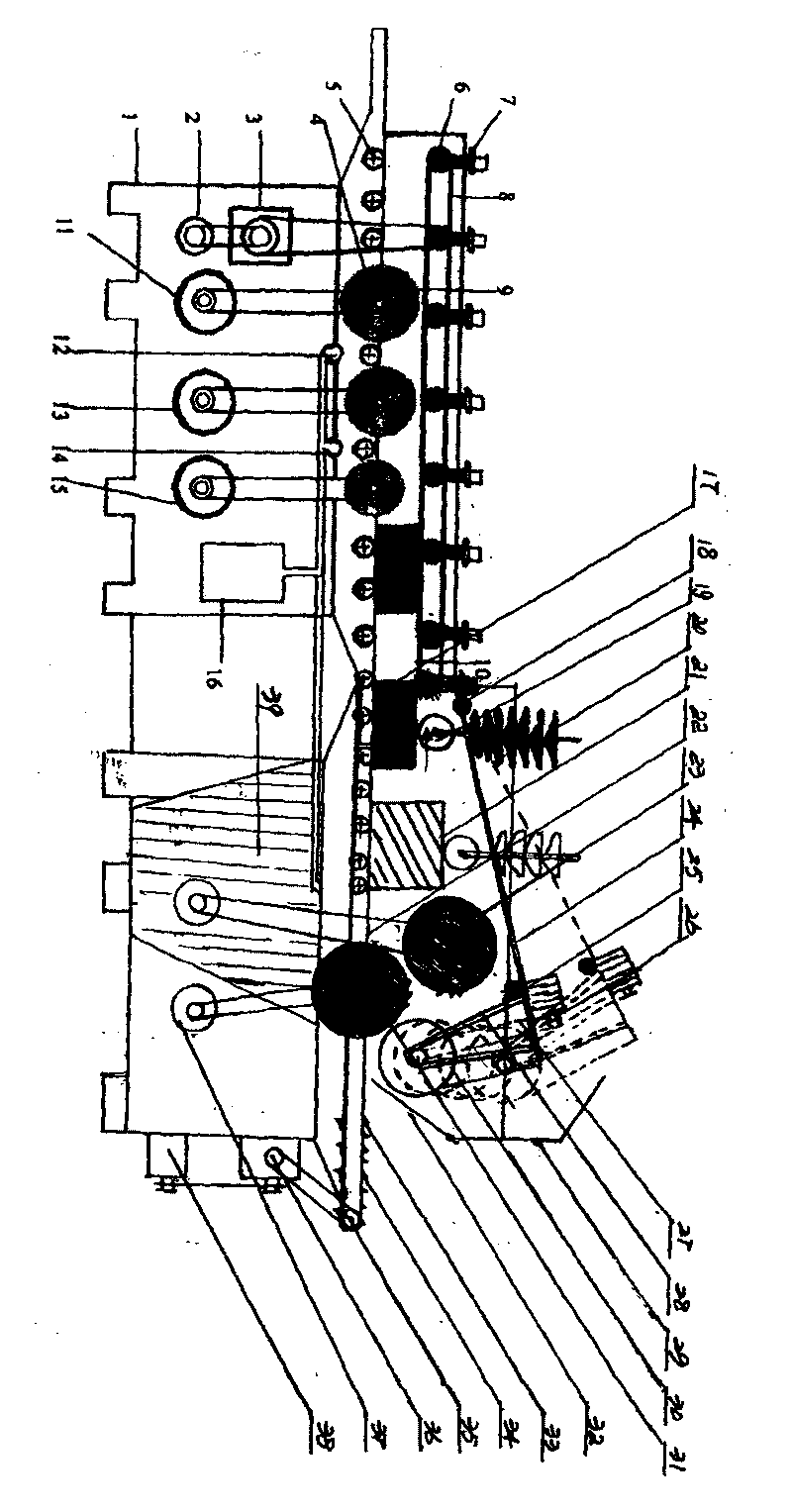

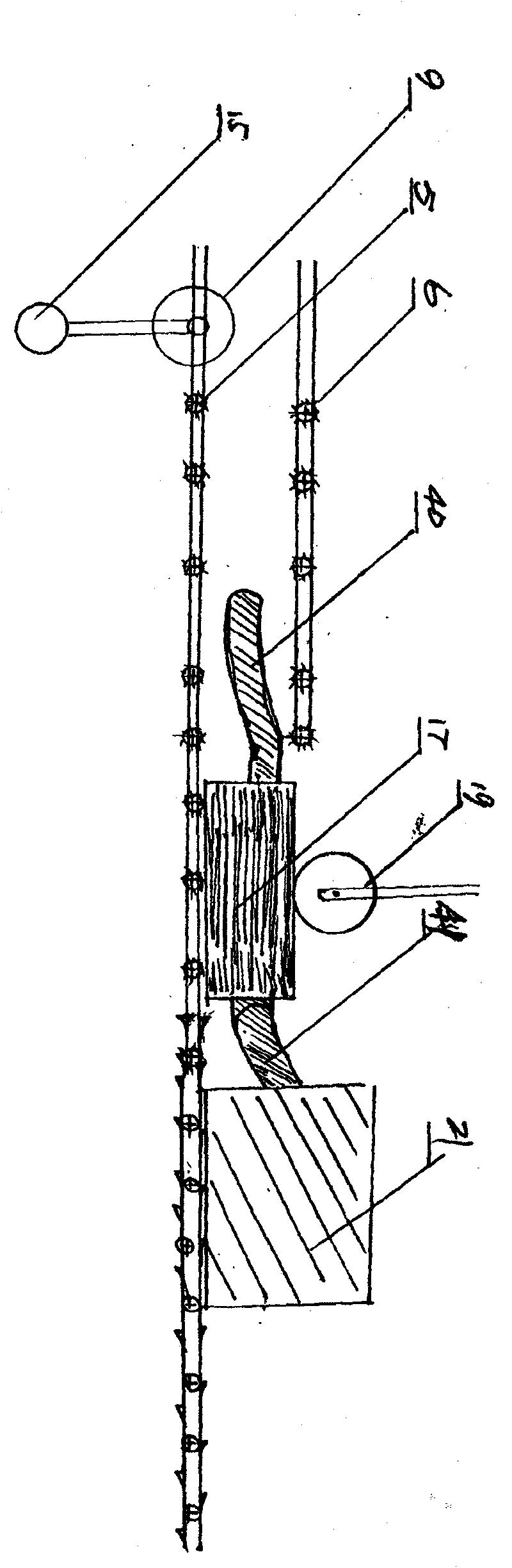

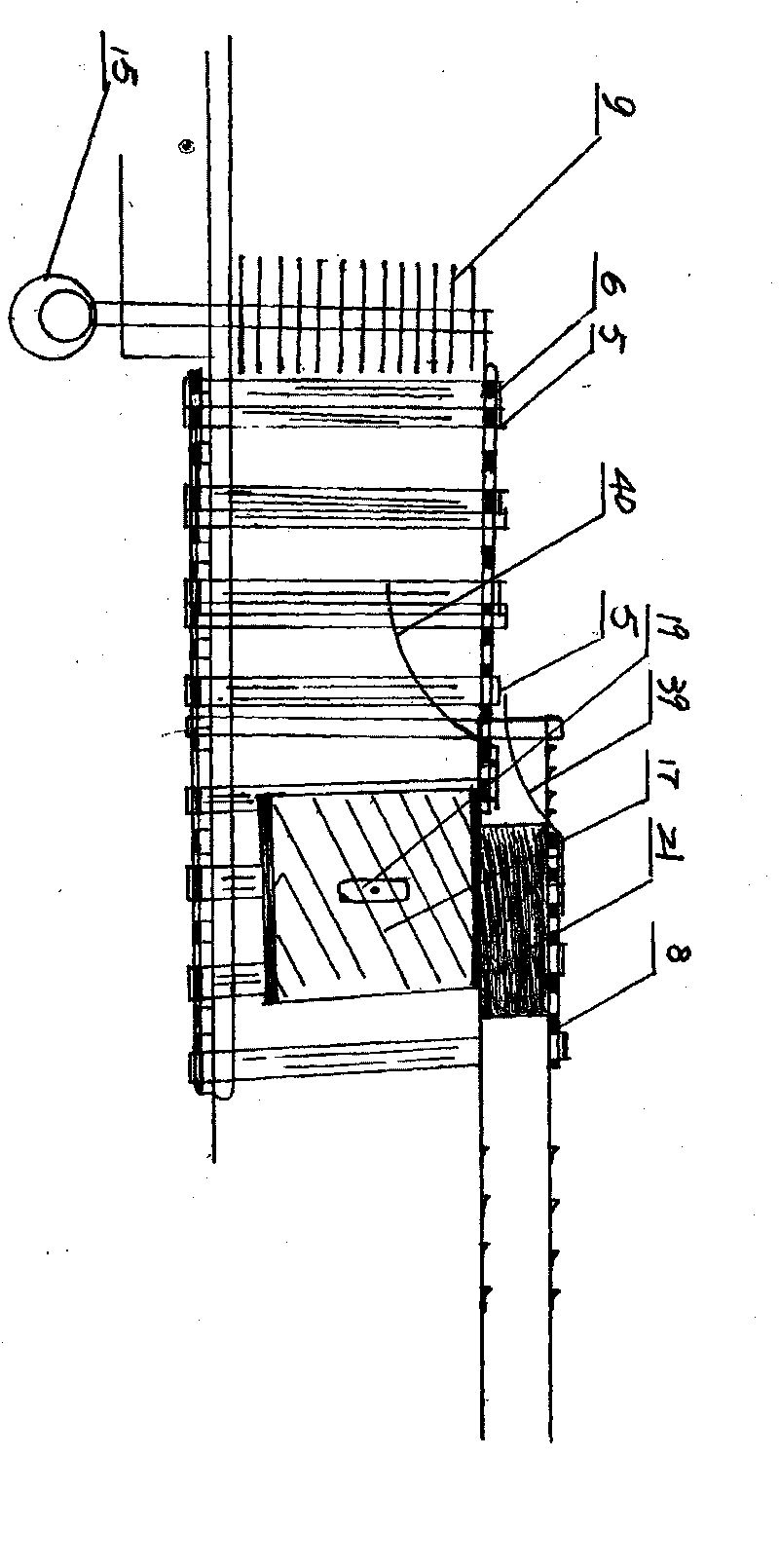

[0021] A door valve steel plate 32 with a safety door 29 is provided above the front end of the workbench of the frame 1, a movable safety cover 24 is provided behind the safety door 29, and an "H"-shaped gear 30, a pressure wheel 30 and a motor 26 are arranged below the movable safety cover 24. Connected, motor 26 is connected with geared 6 by chain 8,27, forms a transmission belt above the platform. On the safety cover 24, movable weight-increasing spacers 20 and pressure rollers 19 are installed, and a saw group 23 and a saw group 31 are respectively connected to the motor 37 at the front end of the workbench, and a toothed chain 33 is provided on the front end of the workbench horizontally. Chain 33 is driven by sprocket wheel 35, gearbox 36 and motor 38, while chain 33 and guide roller 5 are mixed and connected into a horizontal conveyor belt at the middle end of the platform. The booster water pump 16 sprays to the saw blades 23, 31, 4 through 12, 22, the saw blade 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com