Special mechanism for automatically conveying high-temperature saw bit

A kind of mechanical device, technology of saw blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

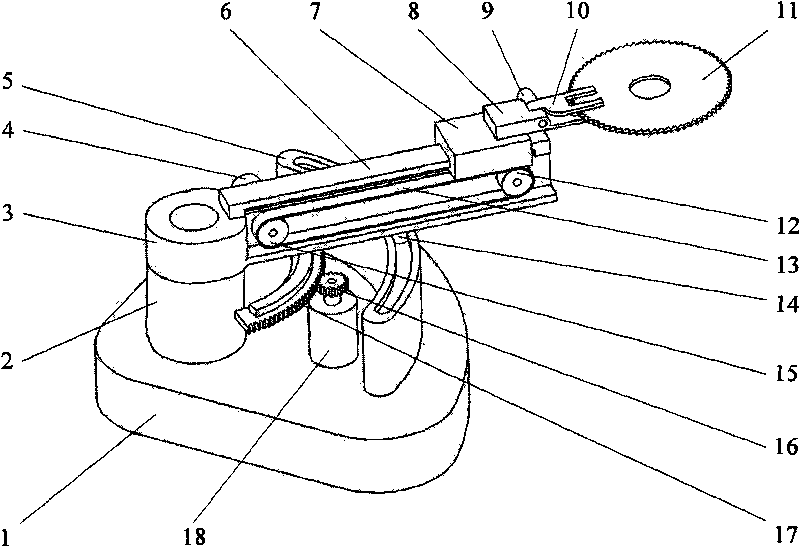

[0012] to combine figure 1 , the special mechanical device for automatic transmission of high-temperature saw blades of the present invention, including a base 1, a column 2, a rotating horizontal frame 3, a sliding drive motor 4, a rotating guide rail 5, a sliding guide rail 6, a slider 7, a clamping and fixing block 8, and a clamping drive Motor 9, movable claw 10, driven pulley 12, conveyor belt 13, positioning pin 14, driving pulley 15, pinion 16, circular arc rack 17, rotating drive motor 18 etc. Wherein, the column 2 is fixed on the base 1, the rotating horizontal frame 3 is connected with the column 2 and can rotate around the column 2, the sliding driving motor 4 is fixed on the rotating horizontal frame 3, and the output shaft of the sliding driving motor 4 is equipped with a driving pulley 15. The driving pulley 15 and the driven pulley 12 fixed on the rotating horizontal frame 3 realize synchronous transmission through the conveyor belt 13, thereby driving the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com