Inclined plane slide block type control arm bush structure

A control arm and slider type technology, which is applied to the cantilever mounted on the pivot, suspension, transportation and packaging, etc., can solve the problems of bolt loosening and fracture, reduce processing costs, increase fit clearance, and assemble simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In conjunction with the accompanying drawings, the following will further explain in detail how the design of the present invention solves many deficiencies in the current control arm bushing.

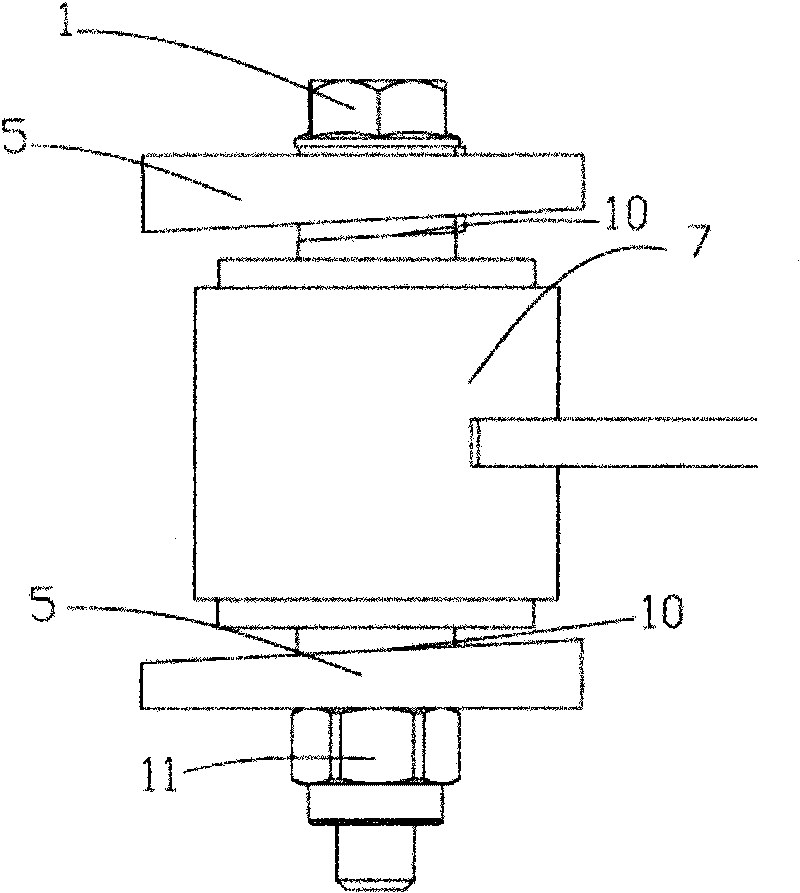

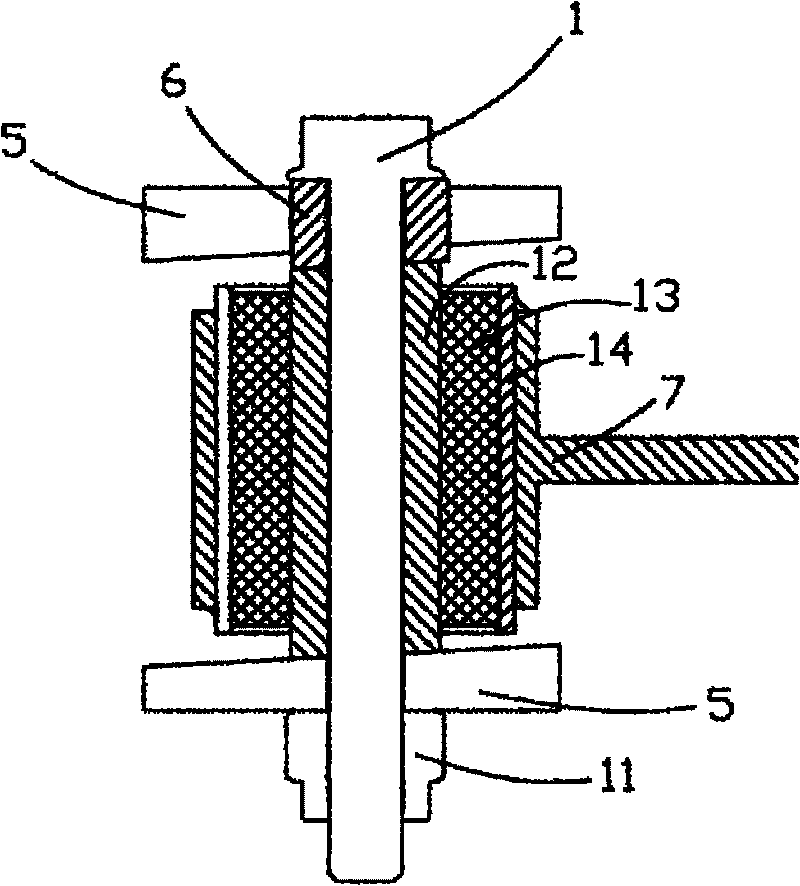

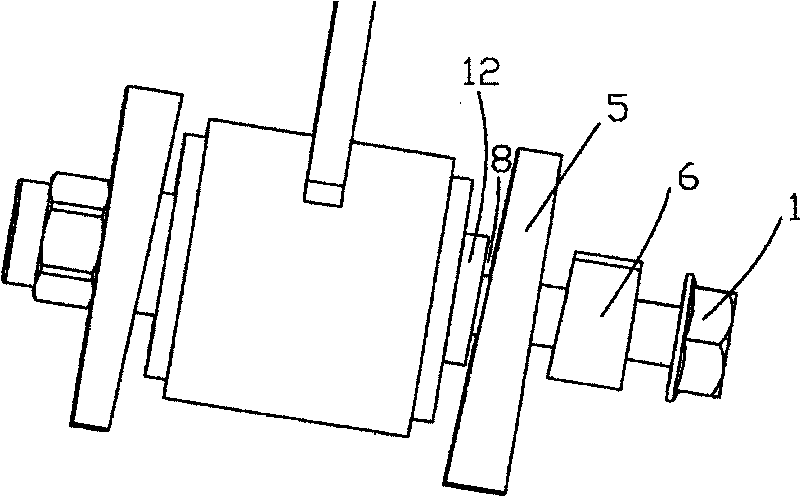

[0016] see figure 1 , 2 , The bushing structure of the control arm disclosed in the present invention comprises: a control arm body 7 , an outer liner 14 , a rubber 13 , an inner liner 12 , a bolt 1 , a nut 11 and a slider 6 . First, the outer liner 14 is fixed to the control arm body 7 through press-fit interference fit, and then the outer liner 14 and the inner liner 12 are connected into one body through the vulcanization of the rubber 13, and the two end faces of the inner liner 12 are inclined planes. 10. The two end slopes 10 are respectively matched with the slope at the end of the nut 11 on the vehicle body (frame, brake) and the slope at the end of the slider 6 at the other end. Through the combination of the bolt 1 and the nut 11, the tightening torque makes the slope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com