Apparatus and method for thermal plasma treatment of solid waste

A technology of solid waste and thermal plasma, applied in the direction of solid waste removal, etc., can solve the problems of short life, full utilization of unfavorable energy, large amount of working gas, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

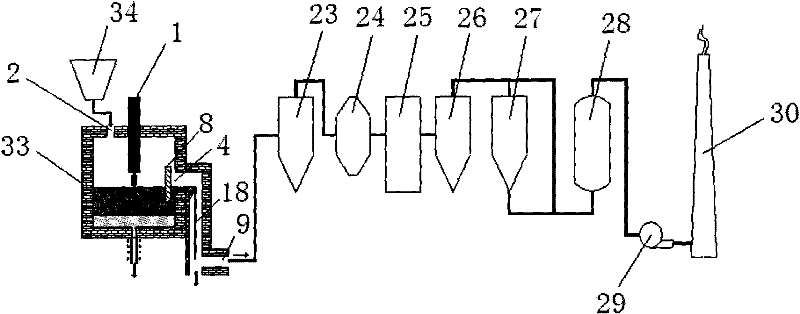

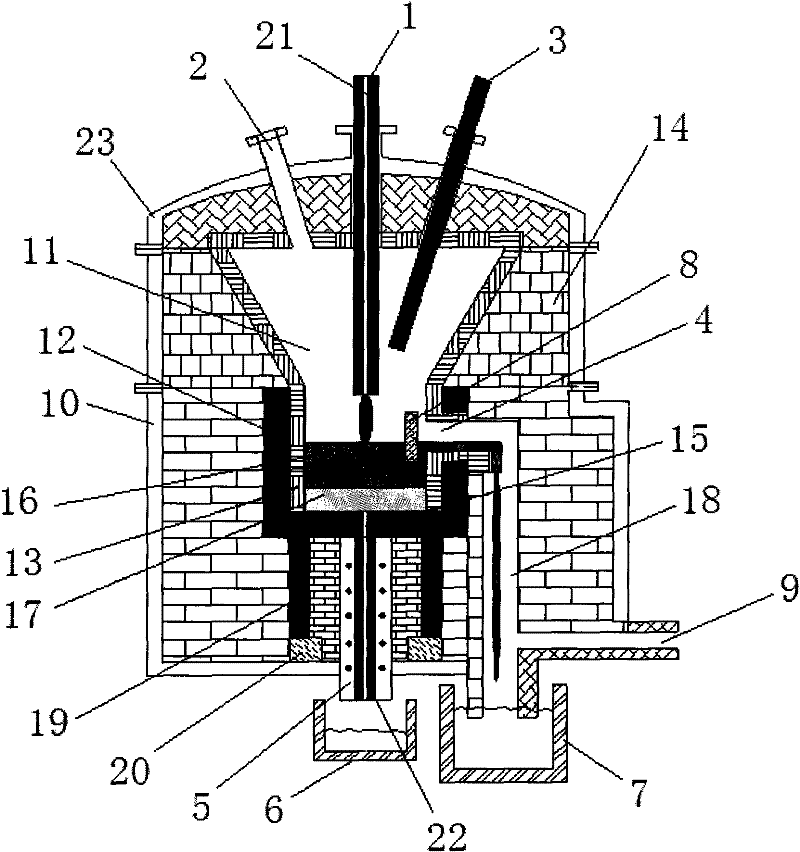

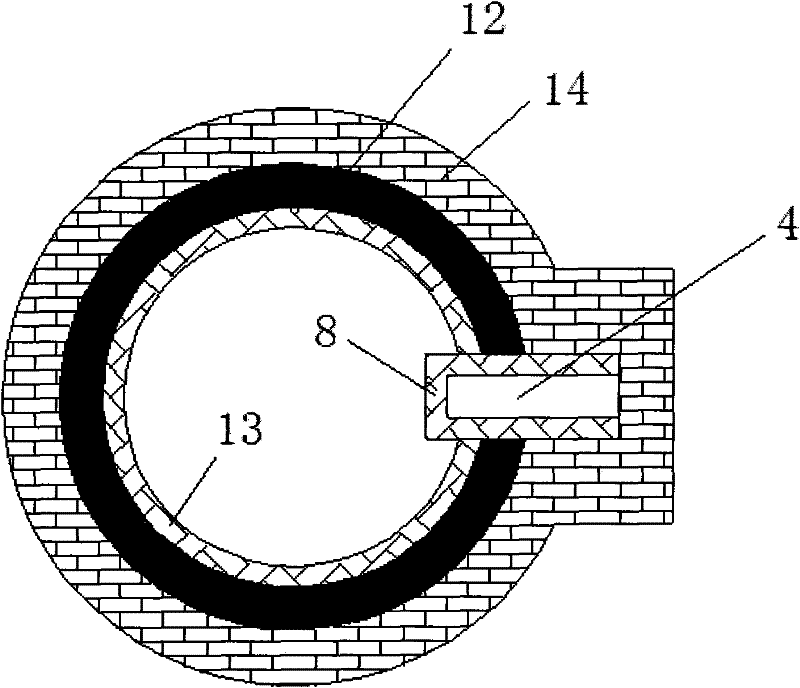

[0027] see figure 1 , 23. A device for thermal plasma treatment of solid waste includes a plasma melting pyrolysis furnace, the furnace body includes a furnace body 10 and a furnace cover 23 that are interlocked, and the middle part of the furnace body 10 is provided with a conductive crucible 12, The conductive crucible 12 is lined with a high-temperature refractory material 13 to form a furnace 11 with a cylindrical lower part and an inverted conical upper part. The furnace cover 23 is provided with a plurality of through holes extending above the furnace, two of which are Cathode 1 and anode 3 pass through the through holes respectively, and are pulled by the electrode lifting mechanism to move up and down. The lower ends of cathode and anode 1 and 3 extend into the furnace 11, and the upper ends are respectively connected to the negative pole and the arc DC power supply through cables. The center of the positive electrode and the cathode 1 has a hole 21 penetrating from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com