Plastic profile multi-position welding machine and welding method

A welding method and welding machine technology, applied in the field of plastic door and window welding, can solve the problems of low work efficiency, unsuitable for large-scale production lines, and many processes, and achieve the effects of ensuring welding quality, convenient and fast work, and accurate relative movement positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

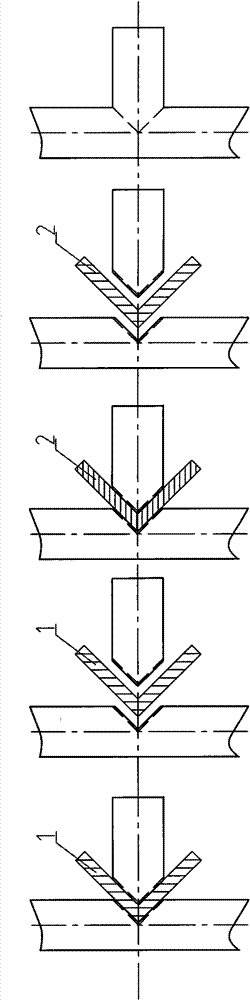

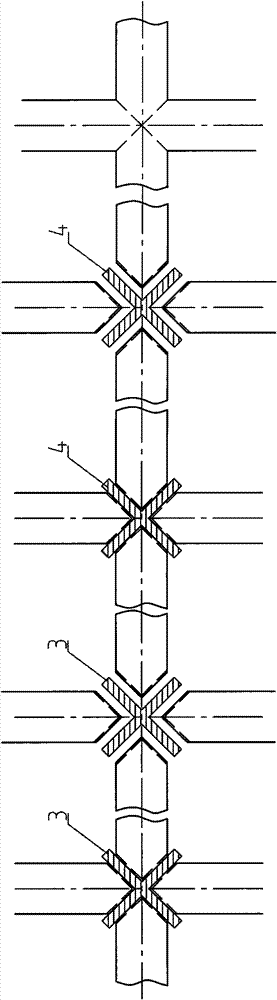

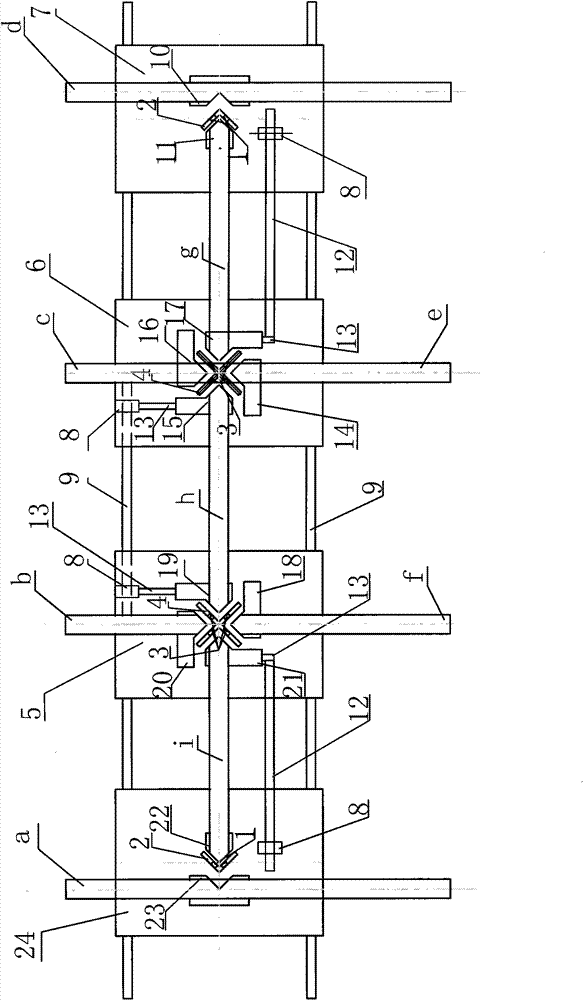

[0041] Such as image 3 Shown is a plastic profile multi-position welding machine according to a selected embodiment of the present invention. The first welding head 24 and the second welding head 7 are arranged on two linear guides 9 along the X axis through the head bottom plate. , The first intermediate welding head 5 and the second intermediate welding head 6, wherein the first welding head 24, the second welding head 7 are used for welding T-shaped plastic stile profiles, the first intermediate welding head 5, The two middle welding heads 6 are used for welding cross-shaped plastic middle stile sections.

[0042] Such as image 3 The first welding head 24 and the second welding head 7 shown both include a front press pliers (that is, the left front press pliers 22, the right front press pliers 11) fixed on the head bottom plate 34, and a rear press that opens and closes relative to the front press pliers. Clamps (ie right rear pressure clamp 10, left rear pressure clamp 23),...

Embodiment 2

[0066] Such as Figure 8 Shown is a plastic profile multi-position welding machine according to a selected embodiment of the present invention. The first welding head 24 and the second welding head 7 are arranged on two linear guides 9 along the X axis through the head bottom plate. And the middle welding head, where the first welding head 24 and the second welding head 7 are used for welding T-shaped plastic stile profiles, and the intermediate welding head is used for welding cross-shaped plastic stile profiles.

[0067] The synchronization structure between each press tongs and adjacent press tongs can be seen in the figure: that is, a press tong in the middle welding head whose work direction is parallel to the X axis is connected to the linear guide through the second brake device on the connecting plate 13 ; The other pressing pliers in the middle welding head, whose work direction is parallel to the X axis, is connected to the first brake device on the first welding head 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com