Preliminary filter for a fuel delivery unit

一种输送单元、预滤器的技术,应用在固定式滤芯过滤器、过滤分离、发动机元件等方向,能够解决大量加工步骤、预滤器制造费用高等问题,达到高自身稳定性、降低制造费用、少制造费用的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

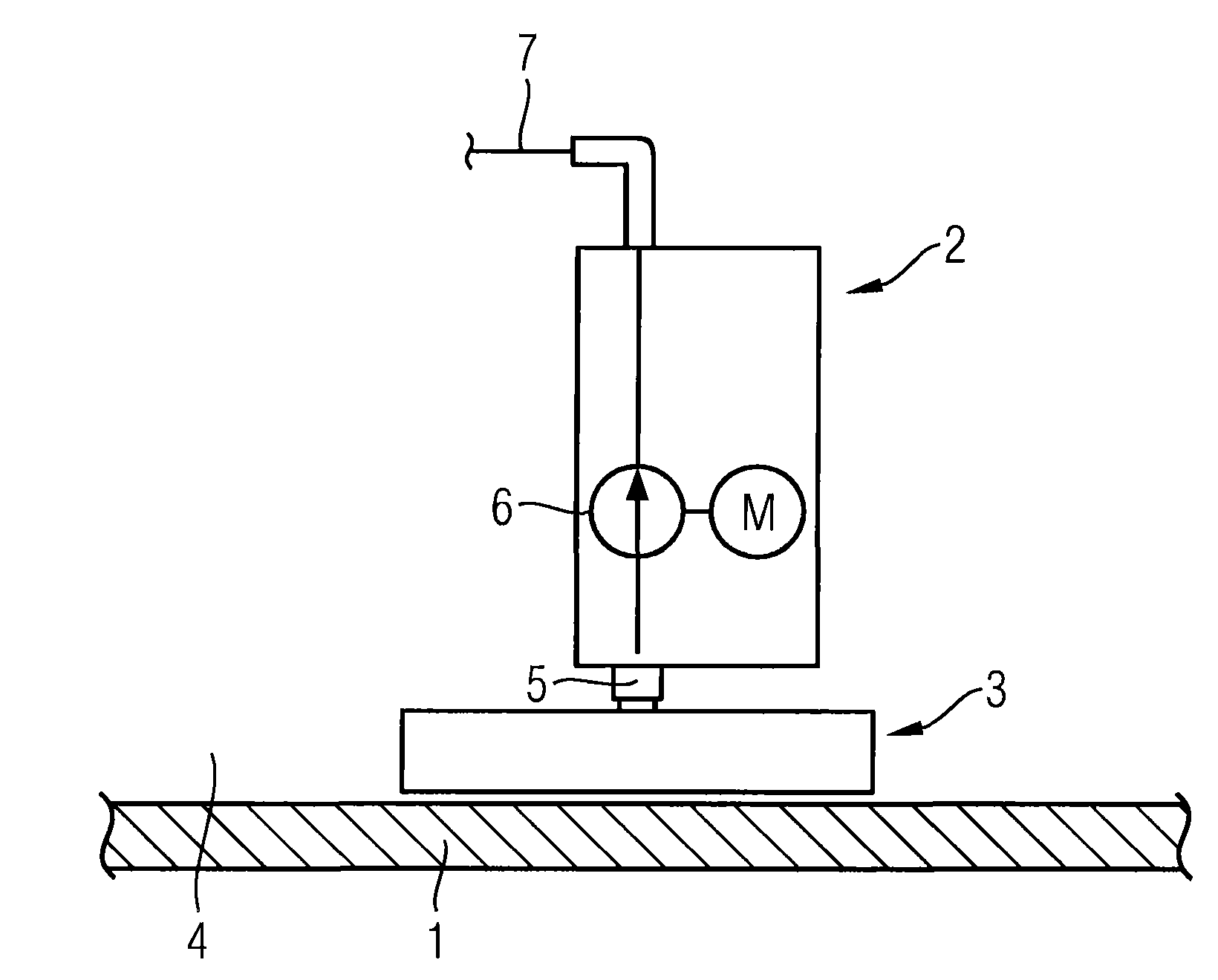

[0023] figure 1 A fuel supply unit 2 with a prefilter 3 arranged on the bottom 1 of a storage tank 4 of a motor vehicle is shown. The prefilter 3 is arranged close to the bottom 1 of the storage container 4 and is connected to the fuel delivery unit 2 via a connecting line 5 . Storage container 4 may be a fuel tank of a motor vehicle. The fuel delivery unit 2 has an electrically driven fuel pump 6 , by means of which fuel is drawn from the bottom 1 of the storage tank 4 via the prefilter 3 and delivered into a feed line 7 , which leads to a not shown internal combustion engine.

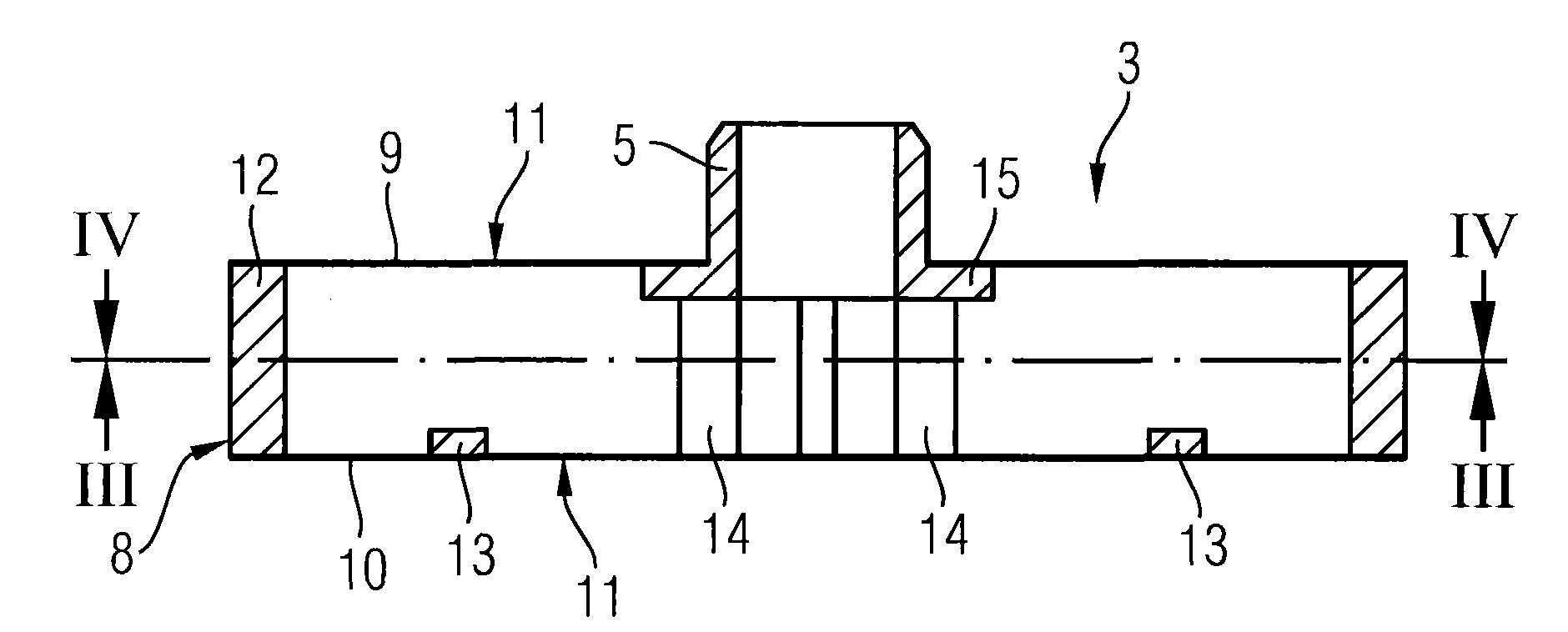

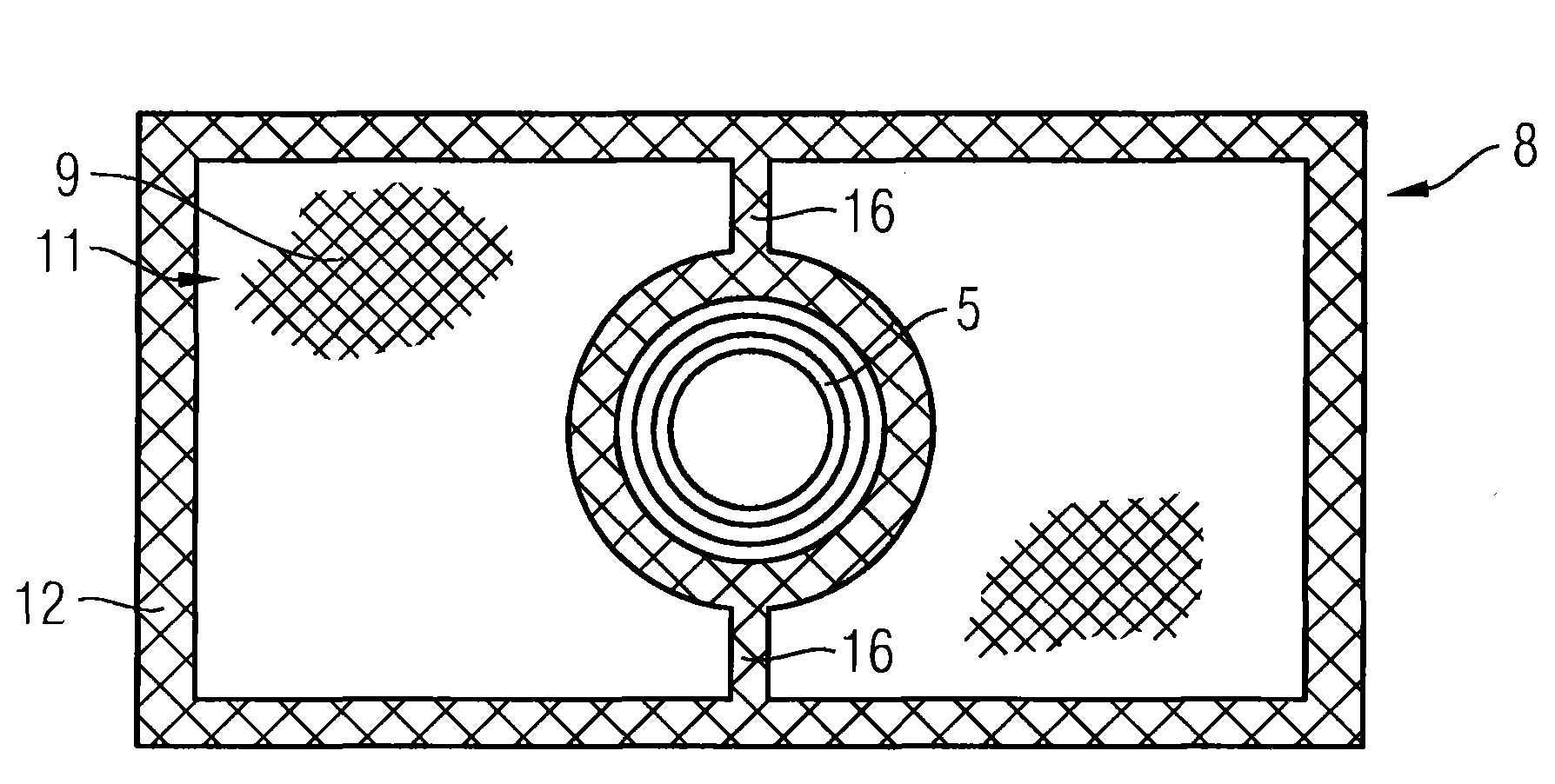

[0024] Prefilter 3 in figure 2 Shown enlarged. It can be seen here that the prefilter 3 has two flat sections 9 , 10 of the filter cloth 11 which are arranged on the carrier 8 . The support part 8 has a support edge 12 to which the sections 9 , 10 of the sieve 11 are fastened at the end faces. The support edge 12 also tensions the sections 9 , 10 of the sieve 11 . For further support, the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com