Copper-clad aluminum flexible cable and manufacture method thereof

A manufacturing method and technology for flexible cables, which are used in cable/conductor manufacturing, wiring harness manufacturing, insulated cables, etc., can solve the problems of hard cables, inability to process, and low tensile force of aluminum materials, and achieve light weight, low cost, and use of copper. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

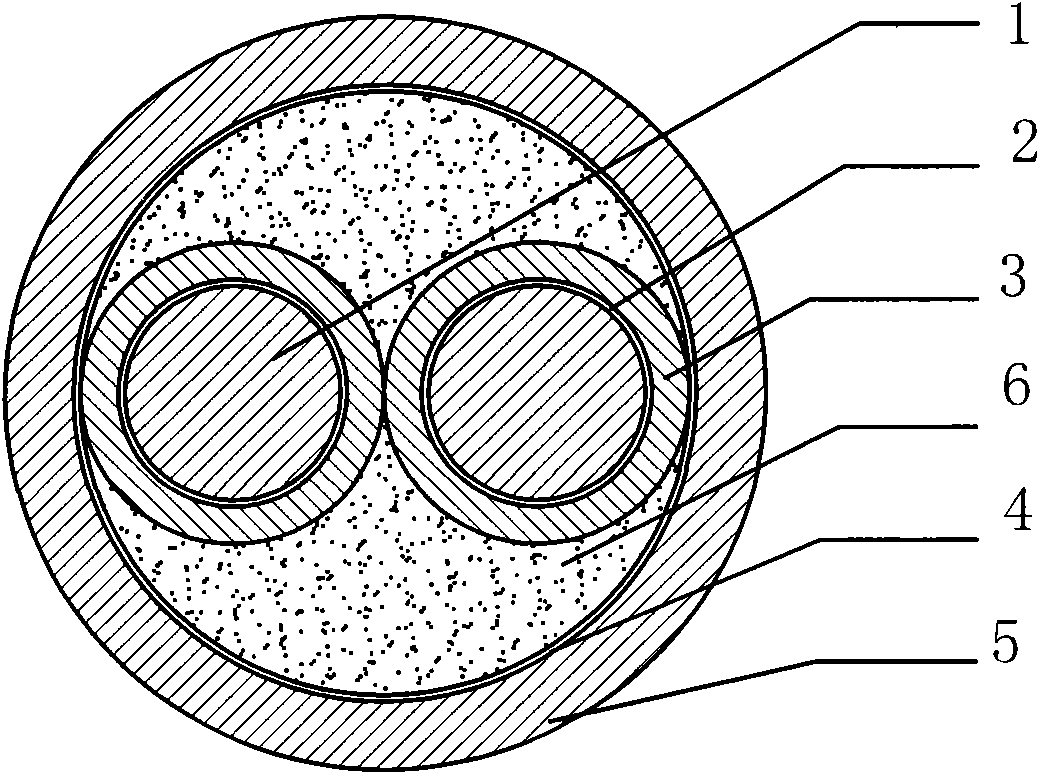

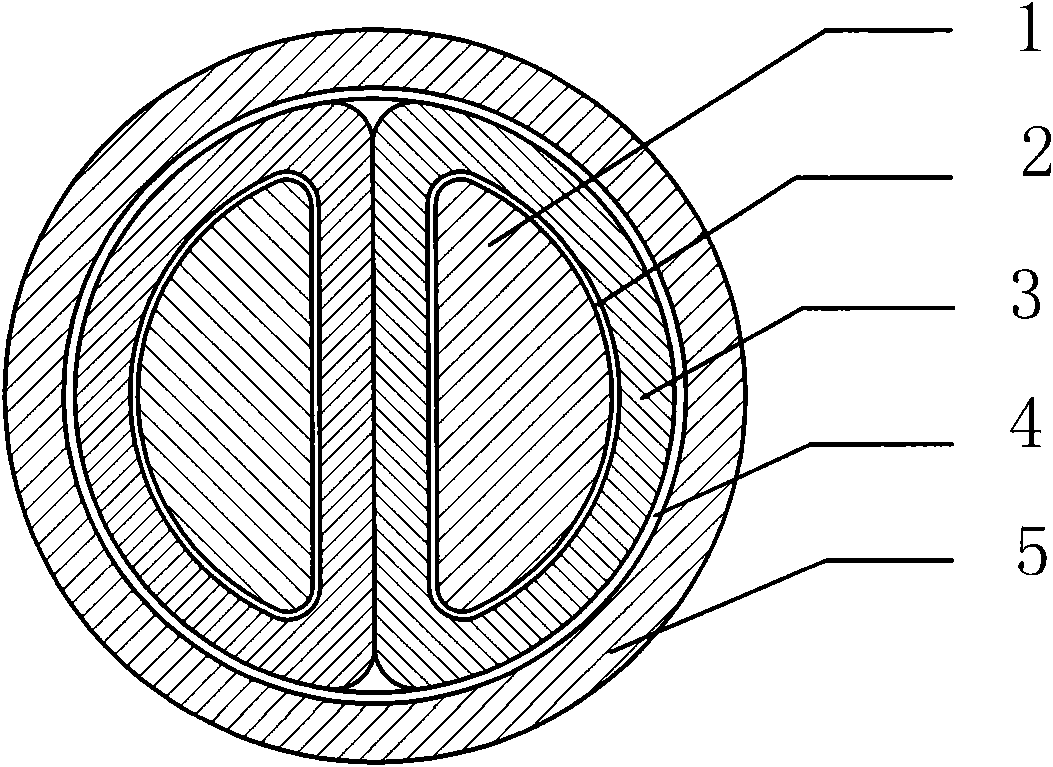

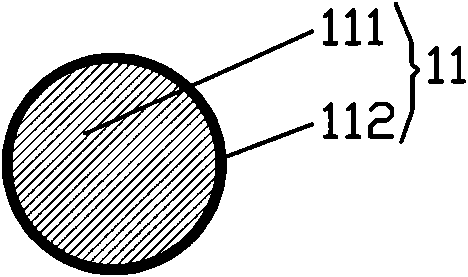

[0058] The present invention adopts the copper-clad aluminum conductive wire core 1 with a copper content of 15% to 30% to manufacture flexible cables, and the copper-clad aluminum conductive wire core 1 with a copper content of 15% to 30% can not only greatly reduce the manufacturing cost, but also Communication quality can also be guaranteed because communication signals can be effectively transmitted using the copper clad layer of the copper-clad aluminum wire or the copper-clad aluminum core. Experiments have shown that when the copper cladding in the copper-clad aluminum wire or the copper-clad aluminum conductive wire core contains 15% to 30% of copper (that is, copper occupies 15% to 30% of the volume of the conductive wire or wire core), its signal The transmission efficiency is basically equivalent to that of a copper conductive core of the same diameter.

[0059] It should be noted that the "copper content" mentioned in the present invention refers to: the percentage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com