Fuel pump

A technology of fuel pump and fuel oil, which is applied in the direction of pumps, pump components, pump devices, etc., can solve the problem of pollutants entering, and achieve the effect of compact design, high efficiency, and avoiding the accumulation of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

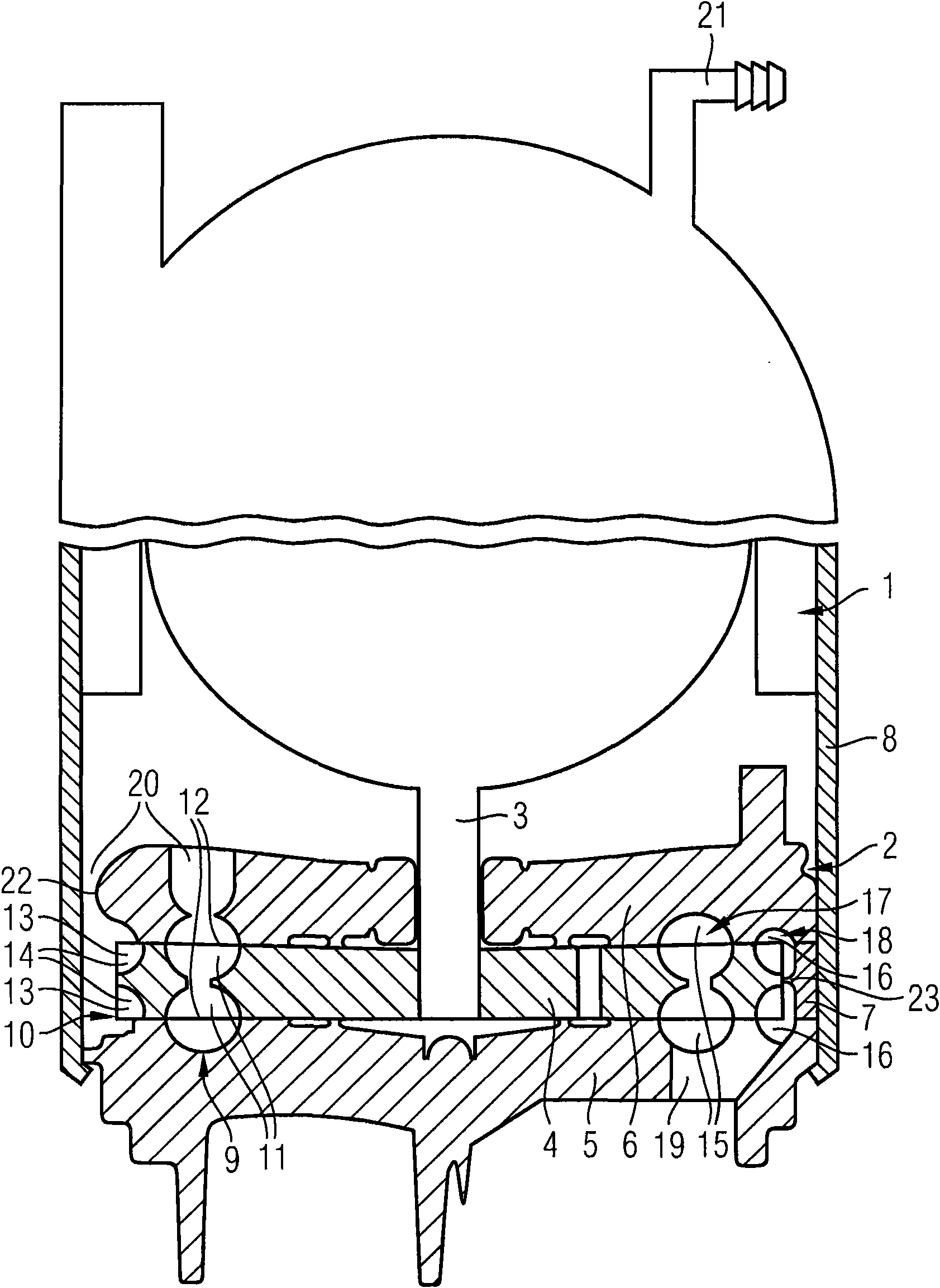

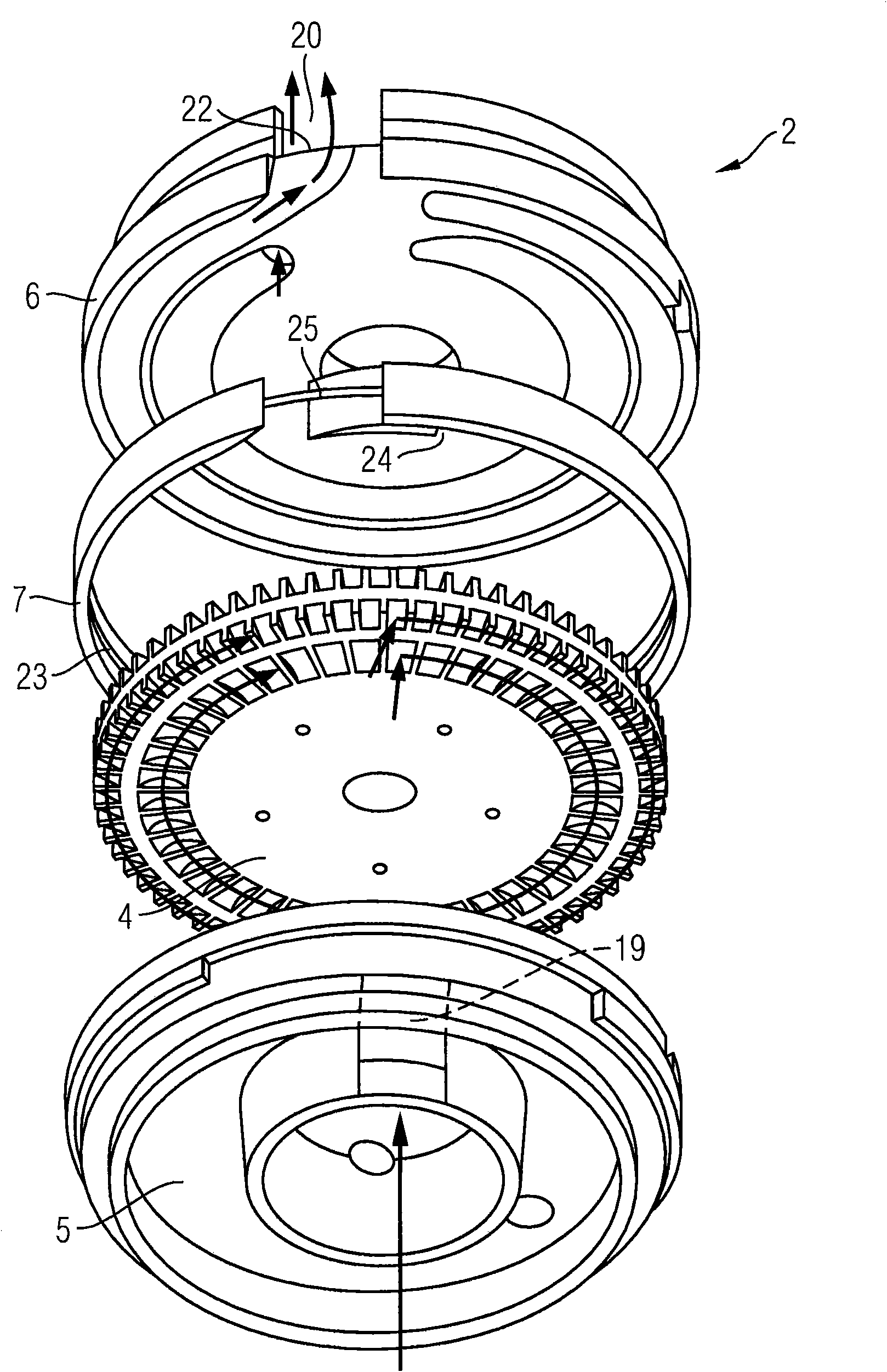

[0019] figure 1 A fuel pump is shown with a pump stage 2 driven by an electric motor 1 . The pump stage 2 has an impeller 4 which is arranged in a rotationally fixed manner on the shaft 3 of the electric machine 1 . The impeller 4 is arranged rotatably between two housing parts 5 , 6 arranged facing one another. The housing parts 5 , 6 are kept spaced apart from each other by a distance ring 7 . The casing 8 of the fuel pump pretensions the housing parts 5 , 6 relative to the spacer ring 7 . The pump stage 2 has a side channel stage 9 and a peripheral stage 10 . The side channel stage 9 has two guide vanes 12 arranged facing one another and delimiting the collar of a vane chamber arranged remote from the radially outer edge in the impeller 4 . The peripheral stage 10 has two guide vanes 14 delimiting a flange of a vane chamber 13 arranged in the radially outer edge of the impeller 4 . The vane chambers 11 , 13 each form a delivery chamber 17 , 18 together with graduated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com