White light-emitting diode

A light-emitting diode and white light technology, applied in electrical components, electric solid-state devices, circuits, etc., can solve problems such as poor luminous efficiency, and achieve the best luminous efficiency, best luminous efficiency and lifespan, and best lifespan effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

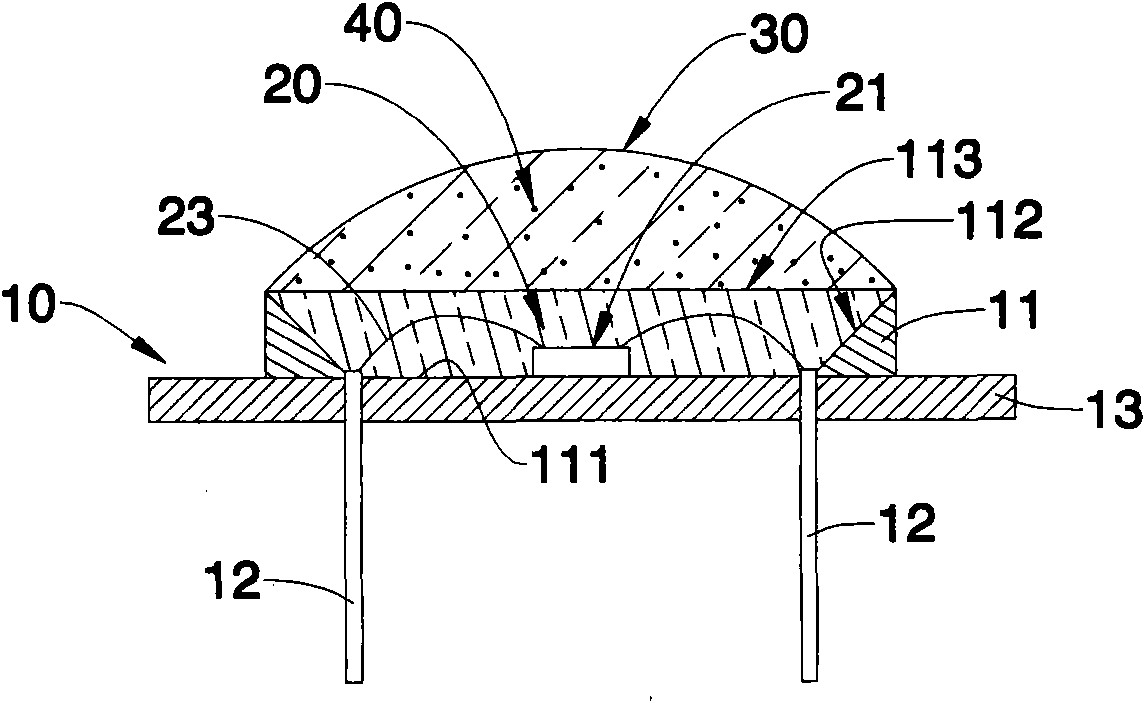

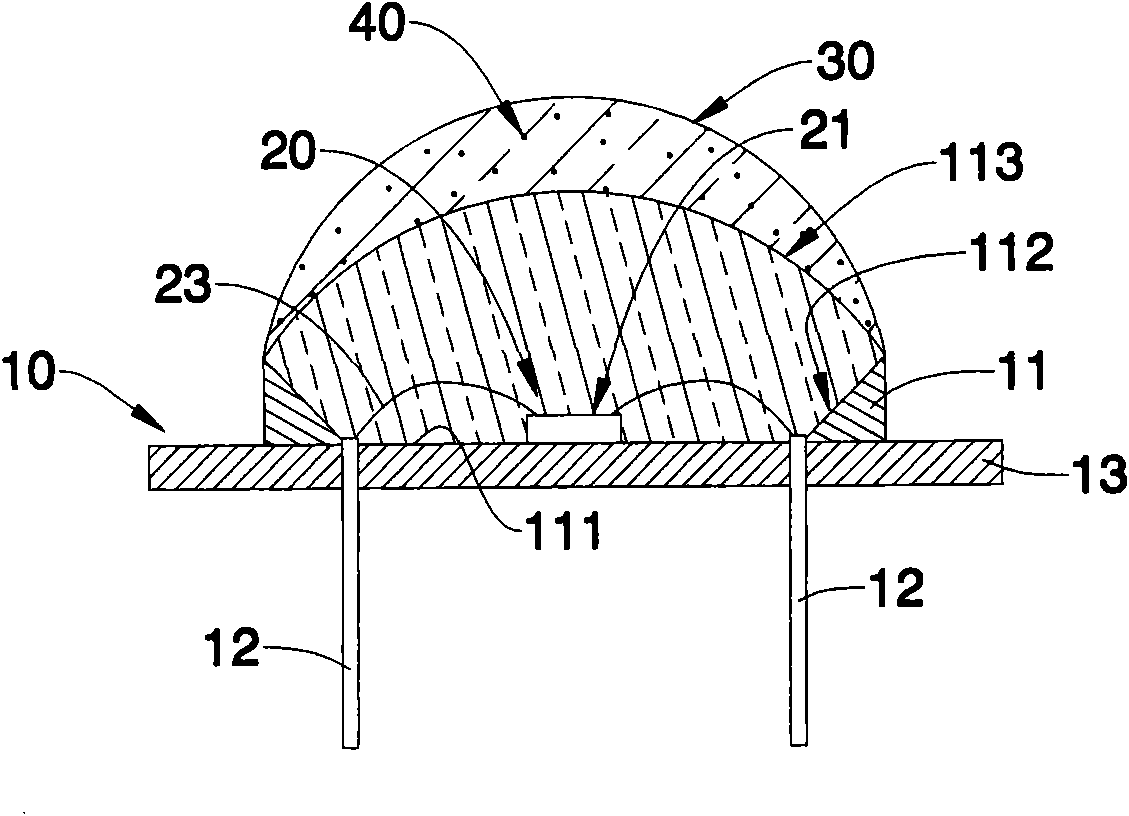

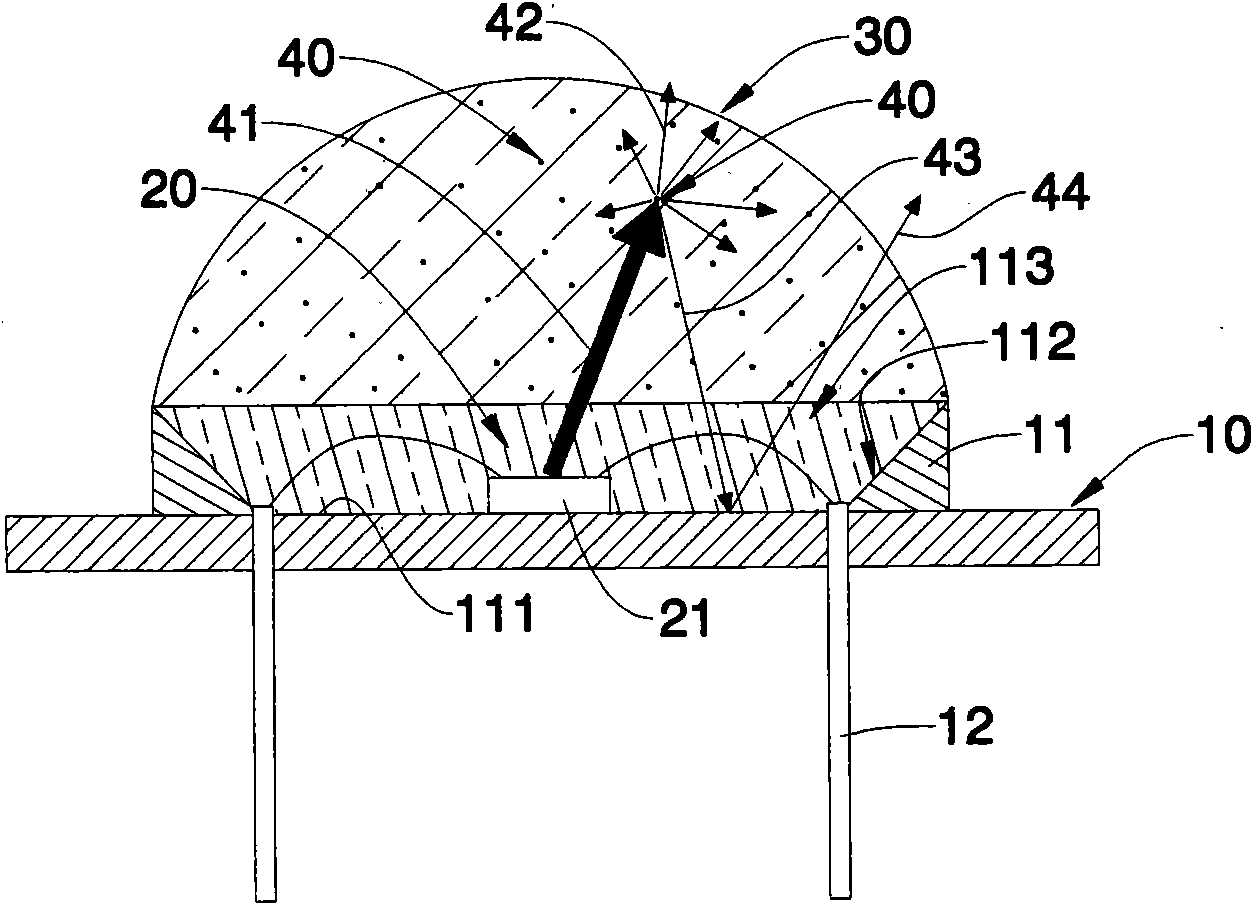

[0054] Such as Figure 1 to Figure 2 As shown, it discloses two kinds of specific and feasible preferred embodiments of the white light emitting diode of the present invention. As can be seen from the figure, the white light emitting diode mainly includes a base (10), a chip group (20), a transparent A light guide layer (113) and a phosphor lens (30), wherein:

[0055] The pedestal (10) comprises a pedestal crystal cup (11) positioned at the top of the pedestal (10), and two pins (12) insulated in the pedestal (10) and extending to the outside of the pedestal (10), the The base crystal cup (11) has a reflective bottom surface (111) and a lateral reflective surface (112) surrounding the reflective bottom surface (111), and the depth of the base crystal cup (11) is greater than 500 μm.

[0056] The chipset (20) is adhesively fixed on the reflective bottom surface (111) in the base crystal cup (11) of the base (10). In this preferred embodiment, the chip (21) is adhesively fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com