Closed loop control method with low nitrogen burning for fire coal boiler

A low-nitrogen combustion and closed-loop control technology, applied in the direction of combustion control, electric controllers, lighting and heating equipment, etc., can solve the problems of boiler economy and optimal control of emission costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

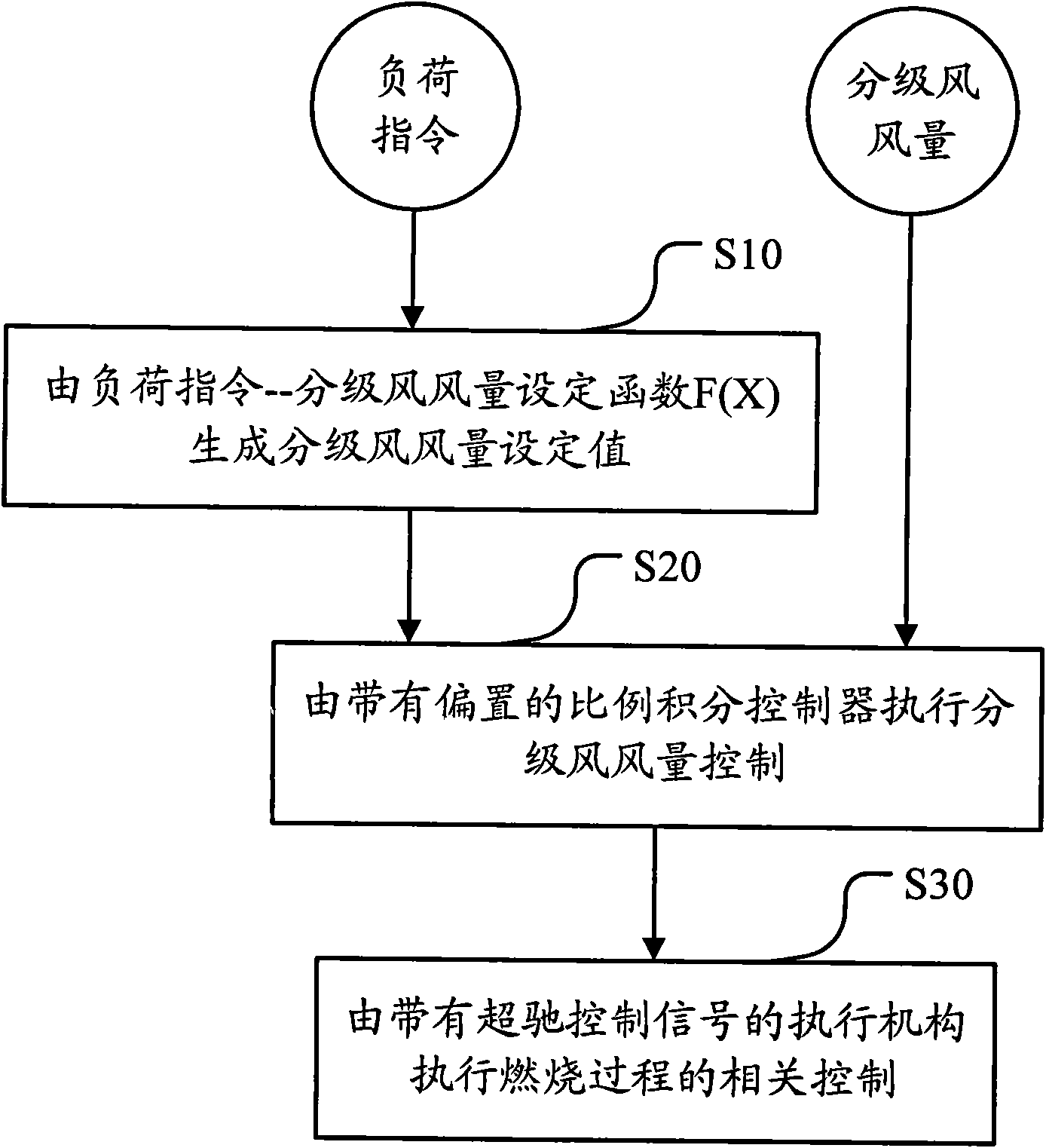

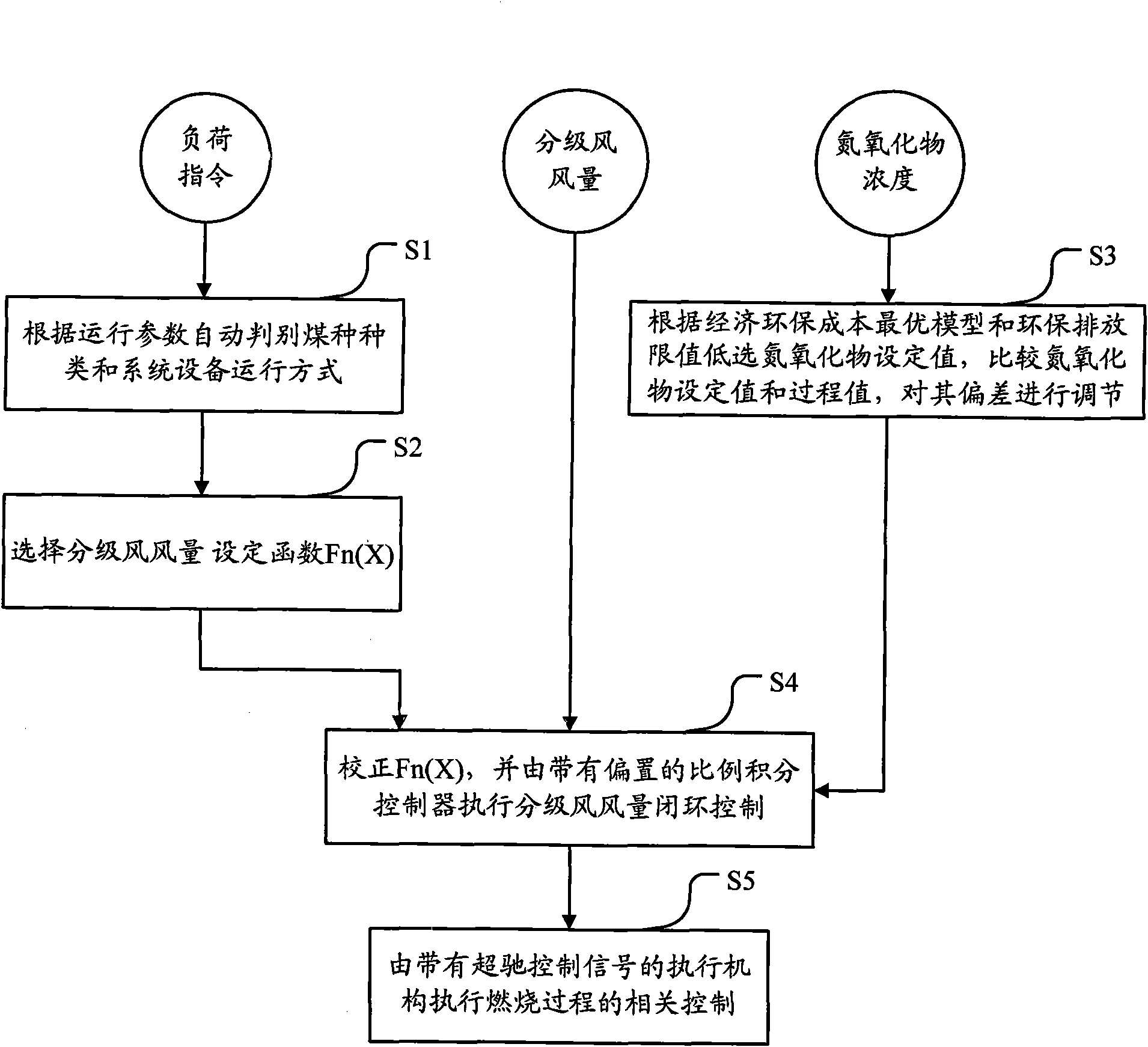

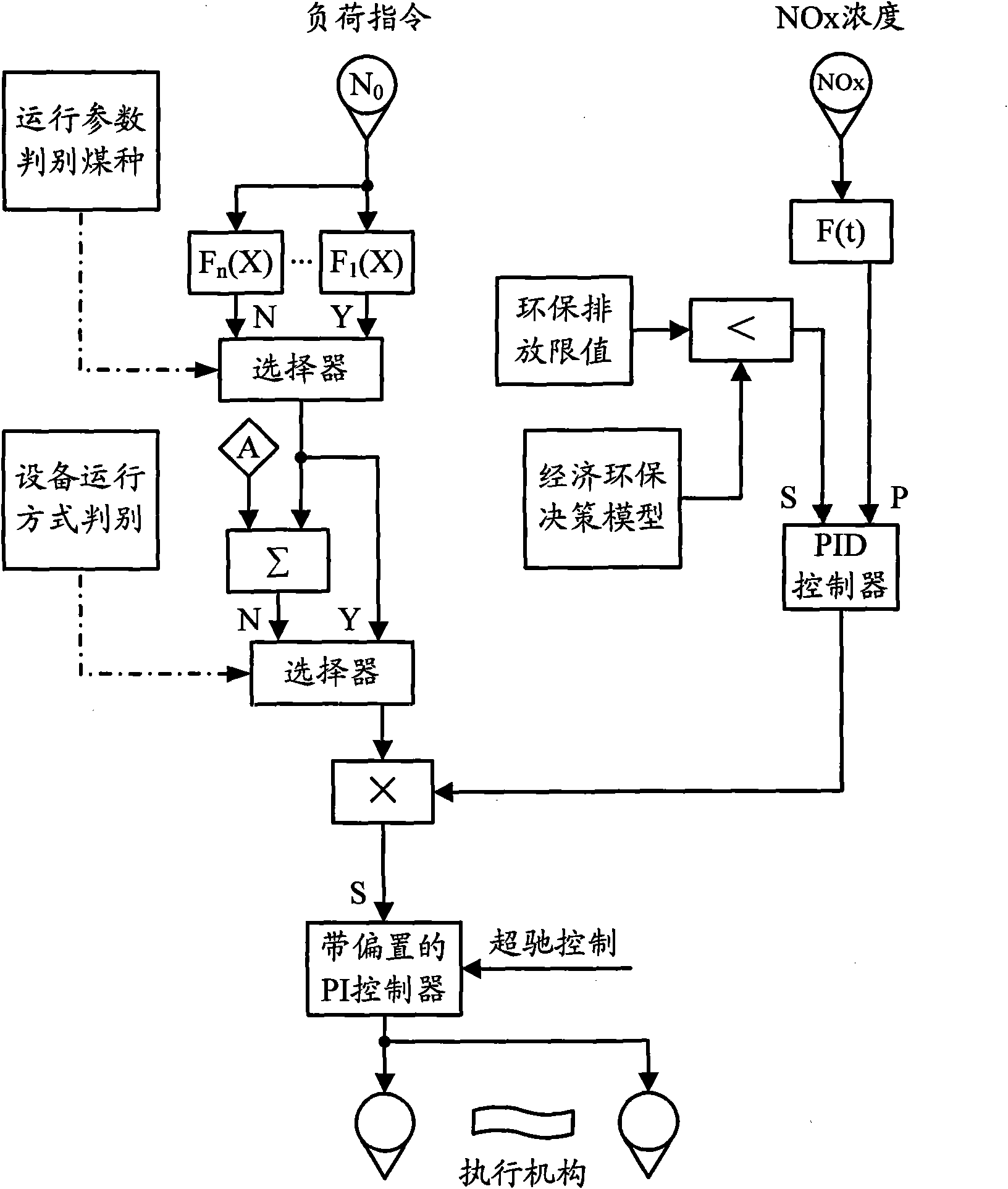

[0012] This invention proposes a low-nitrogen combustion closed-loop control method for coal-fired boilers, which is applied to coal-fired boilers. Please combine figure 2 A simplified flowchart of the combustion closed-loop control method of the present invention is shown. As shown in the figure, the combustion closed-loop control method of the present invention adopts the intelligent feed-forward plus optimal feedback cascade adjustment control technology of predictive optimization. In a preferred embodiment of the present invention, it includes multiple different graded air volume settings function, denoted as F 1 (X) to F n (X) is used to set the adjustment volume (that is, the classified air volume). Each grading air volume setting function is applicable to different environments, such as different coal types and different equipment operation modes.

[0013] The low-nitrogen combustion closed-loop control method of the present invention includes the following steps: f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com