Apparatus for conveying substrates, method and apparatus for locating substrates

A substrate handling and substrate technology, which is applied in transportation and packaging, lighting and heating equipment, furnace components, etc., can solve the problems that devices cannot be combined, and achieve the effect of simplified structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0055]

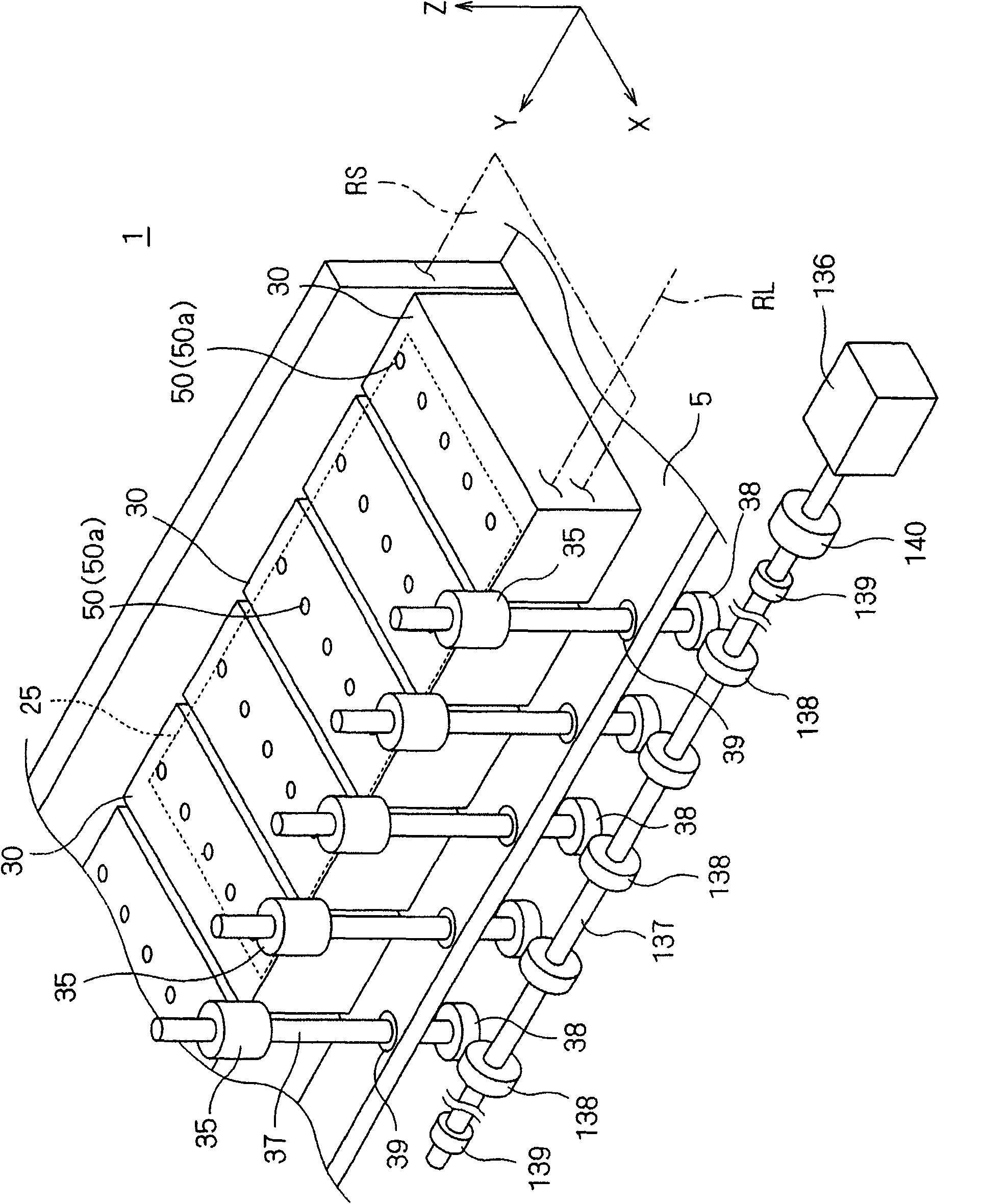

[0056] figure 1 It is a perspective view which shows the schematic structure of the main body of the board|substrate conveyance apparatus 1 which concerns on embodiment of this invention. in the figure 1 In , for the convenience of illustration and description, it is defined that the Z-axis direction represents the vertical direction, and the XY plane represents the horizontal plane. However, these are defined for the convenience of grasping the positional relationship, and do not limit each direction described below. The same applies to the following figures. figure 2 This is a cross-sectional view obtained by cutting a perspective view of the main body of the board transfer device 1 in the XZ plane.

[0057] figure 1 The illustrated substrate transfer apparatus 1 can move from the (+Y) direction (upstream side) to the (-Y) direction (downstream side), keeping the rectangular substrate 25 floating on the substrate transfer table 30 without changing the substra...

no. 2 approach

[0075] In the first embodiment, one type of air ejection hole 50 is used, which is a composite direction of the first direction ((+Z) direction) and the second direction ((+X) direction), but it is not limited thereto. That is, the first air ejection hole 50a that ejects compressed air toward an oblique direction and the air ejection hole 50 (second air ejection hole 50b) that ejects compressed air toward a direction perpendicular to the lower surface of the substrate 25 are used in combination, The present invention can also be implemented.

[0076] As the main form of such combinations, such as Figure 6 As shown schematically by classification, (a) about the first air ejection hole 50a ( Figure 6 in the white circle) and the second air ejection hole 50b ( Figure 6 There are 3 types of arrangements of the black circles in (b), and there are 3 types of arrangements of substrate transfer tables in (b), so that there are 9 types in total.

[0077] In the following, the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com