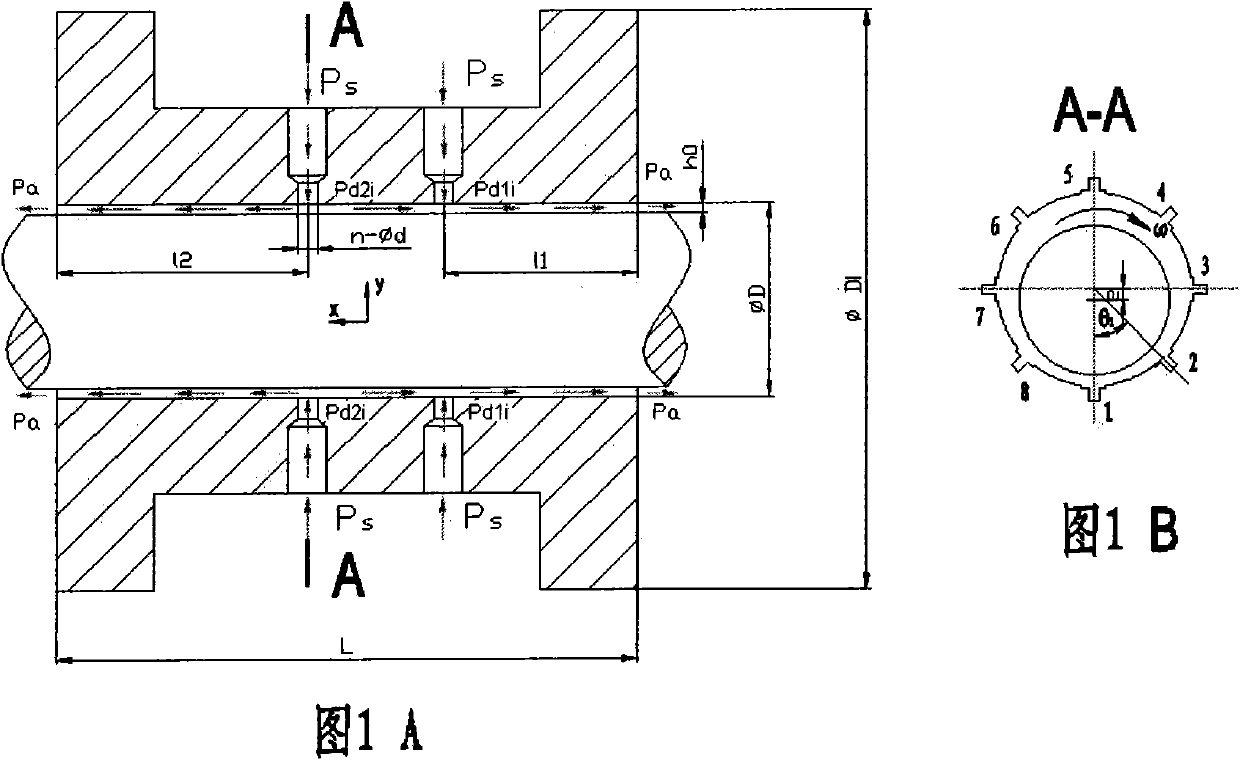

Method for designing optimal static parameter of radial static pressure gas bearing of turbine expansion engine

A technology of static pressure gas bearing and turboexpander, which is applied in the directions of bearings, shafts and bearings, mechanical equipment, etc., can solve the problem of low precision and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

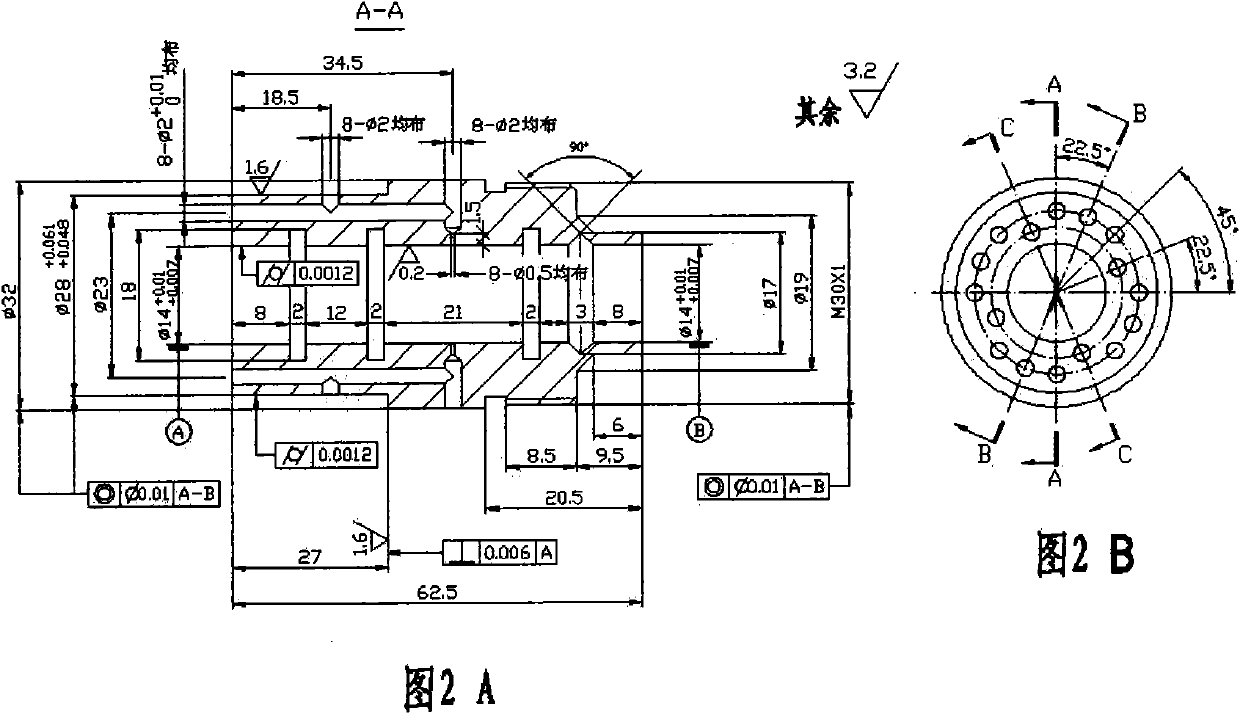

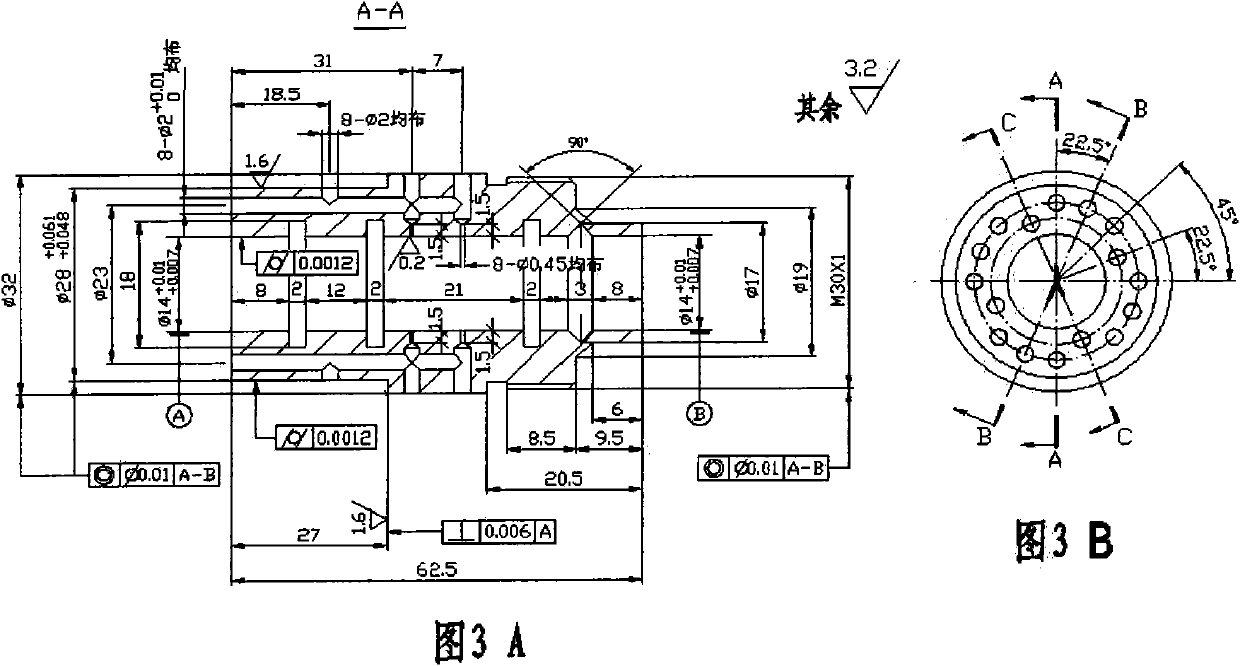

[0104] Such as figure 2 It is an existing imported Russian oil-gas mixed helium turboexpander radial throttle small hole static pressure gas bearing, the specific parameters are as follows: single row of gas supply, each row of gas supply small holes n=8, small hole diameter d= 0.5mm, air supply pressure p s =19bar, diameter air film thickness h 0 =0.045mm, bearing length L=28.5mm, journal diameter D=12mm, rated speed 180krpm. According to the above parameters, according to the design process of the design method of the present invention Figure 4 , the performance parameters of the gas bearing are calculated as follows: total flow M · = 0.337 g / s , Stiffness coefficient K W =2.33, carrying capacity W=1.06×10 2 N, frictional power loss F T =8.13W, the above results are very close to the performance parameters provided by Russian Turbine Corporation, and the calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com