Powdered carbon box

A technology of toner cartridges and photoreceptors, which is applied in the fields of electrography, optics, instruments, etc., can solve the problems of complicated loading and unloading of the developing unit and photoreceptor unit of the toner cartridge, high production dimensional accuracy requirements, etc., and achieves convenient installation and operation, and production The effect of high precision requirements and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

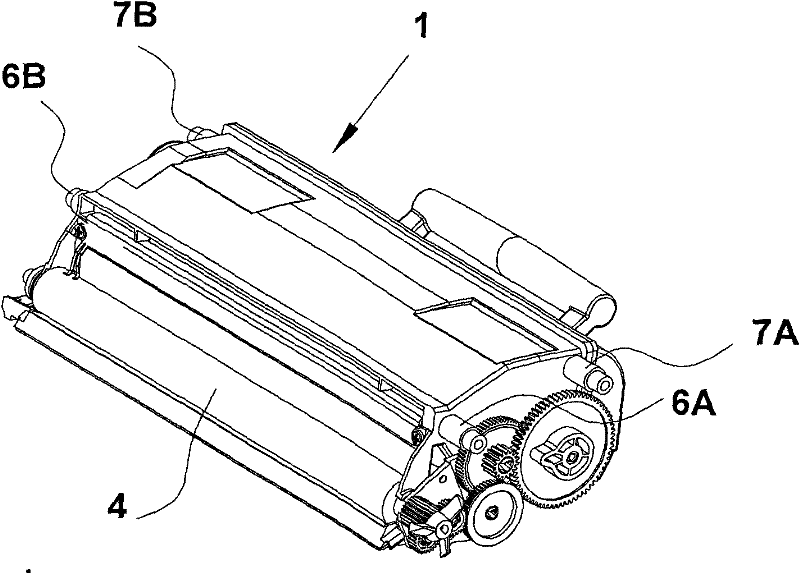

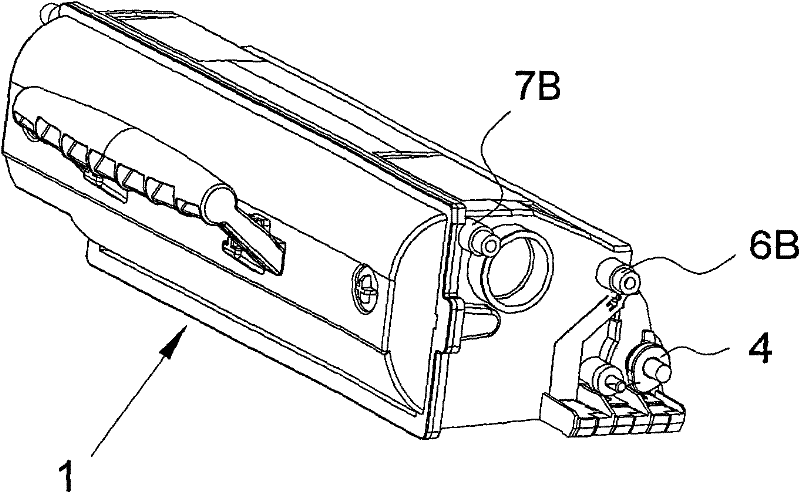

[0036] like figure 1 , figure 2 As shown, the toner cartridge is mainly composed of a developing unit 1 and a photoreceptor unit 2 . The developing unit 1 includes a developing roller 4 , and the two sides of the developing unit 1 are respectively provided with front guide posts 6A, 6B and rear guide posts 7A, 7B.

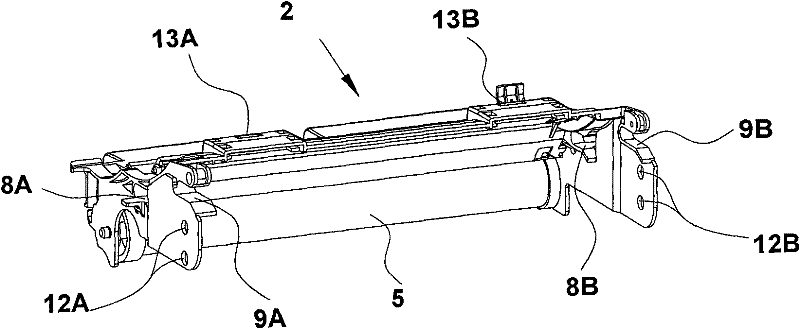

[0037] like image 3 , Figure 4 As shown, the photoreceptor unit 2 includes a photoreceptor drum 5, and front guide rails 8A, 8B, rear guide rails 9A, 9B, side flap holes 12A, 12B and top strap holes 13A, 13B are respectively provided on both sides of the photoreceptor unit 2.

[0038] like Figure 5 , Image 6 As shown, side buckles 10A, 10B, top buckles 11A, 11B and compression springs 14A, 14B are provided on the elastic brackets 3A, 3B.

[0039] like Figure 7 , Figure 8 As shown, since the distance between the two sides of the photoreceptor unit 2 is slightly larger than the size between the two sides of the developing unit 1, the developing unit 1 ...

Embodiment 2

[0043] like Figure 11 , 12 , 13, 14 are another embodiment of the present invention;

[0044] Compared with Embodiment 1, the developing unit 1 adopted in this embodiment has only the front guide posts 6A and 6B, and the photoreceptor unit 2 has only the front guide rails 8A and 8B. The process box structure that the present embodiment adopts does not have embodiment one described rear guide post 7A, 7B and rear guide rail 9A and 9B, on the elastic support 3A' more than embodiment one described elastic support 3A a supporting plate 15A. The support plate 15A is used to support the rear of the developing unit and prevent it from falling.

[0045]The compression springs 14A and 14B used in the present invention can also be a group of magnets, one of which is arranged on the developing unit 1, and the other is arranged on the photoreceptor unit 2, and the magnetic force of the group of magnets makes the developing unit 1 The developing roller 4 moves toward the direction clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com