Graphite block hole type down-firing triad hydrochloric acid synthetic furnace

A three-in-one hydrochloric acid, block-hole type technology, applied in the direction of sustainable manufacturing/processing, climate sustainability, chemical industry, etc., to achieve the effect of compact structure, lower conveying pressure, and lower overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

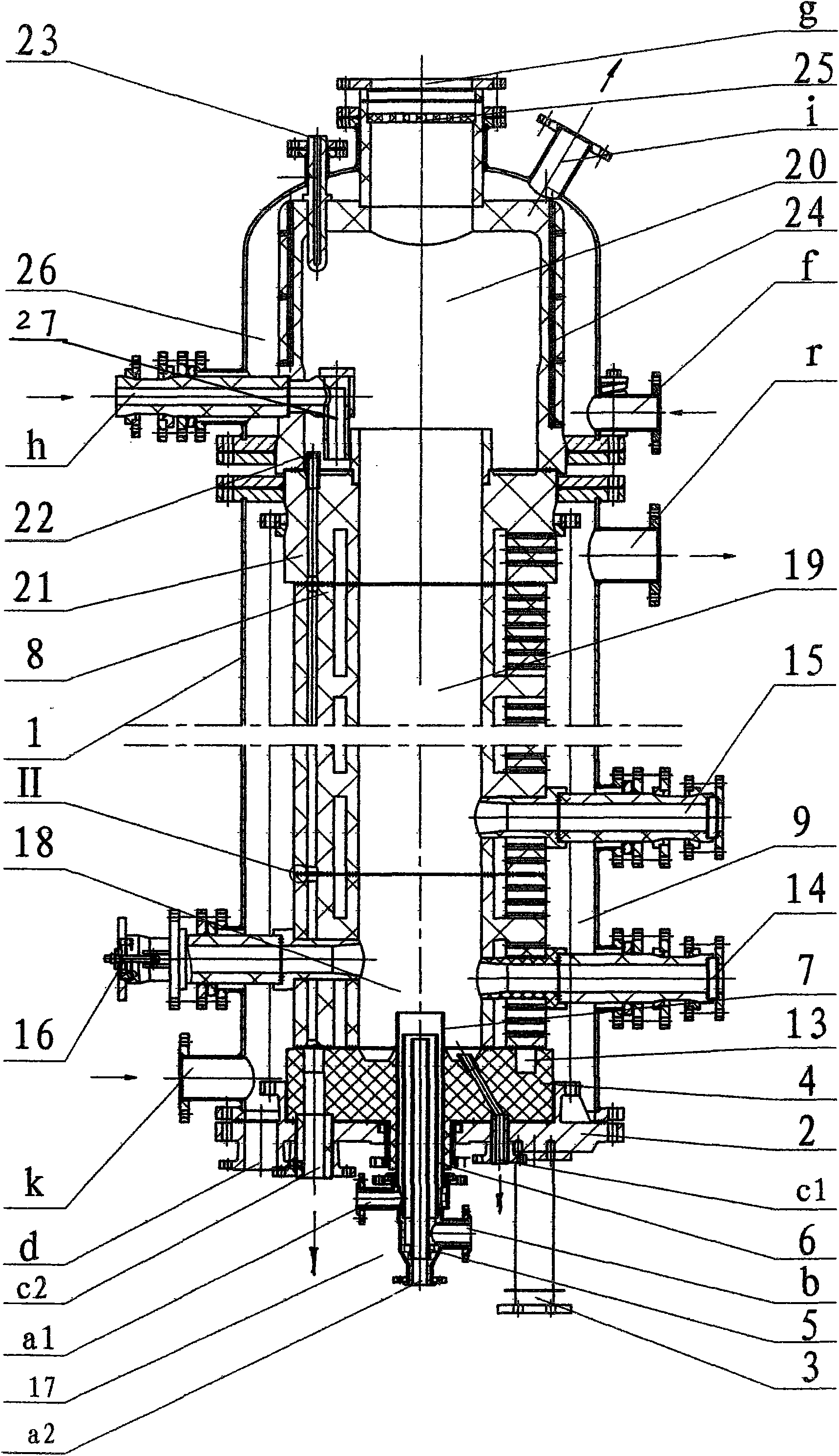

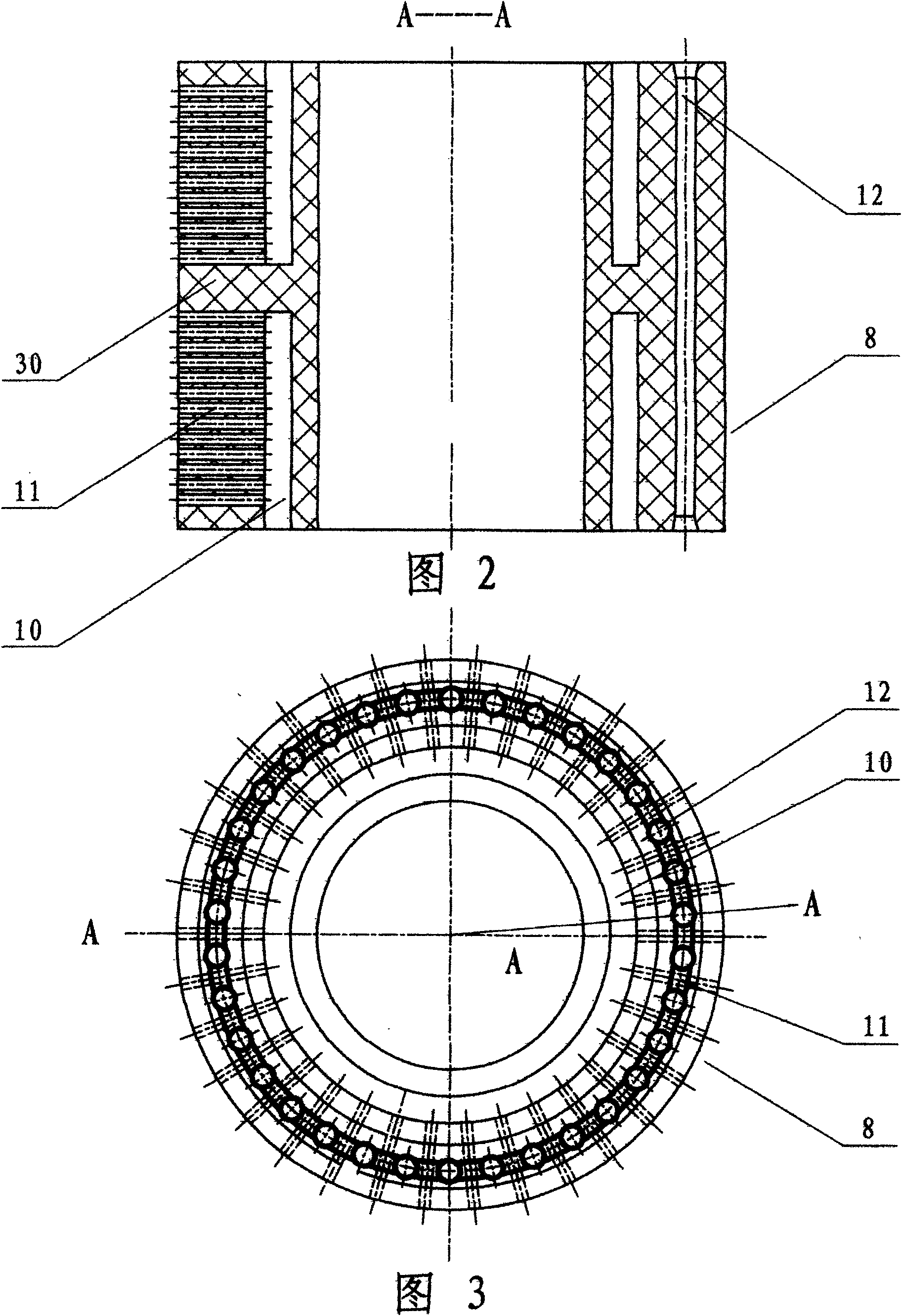

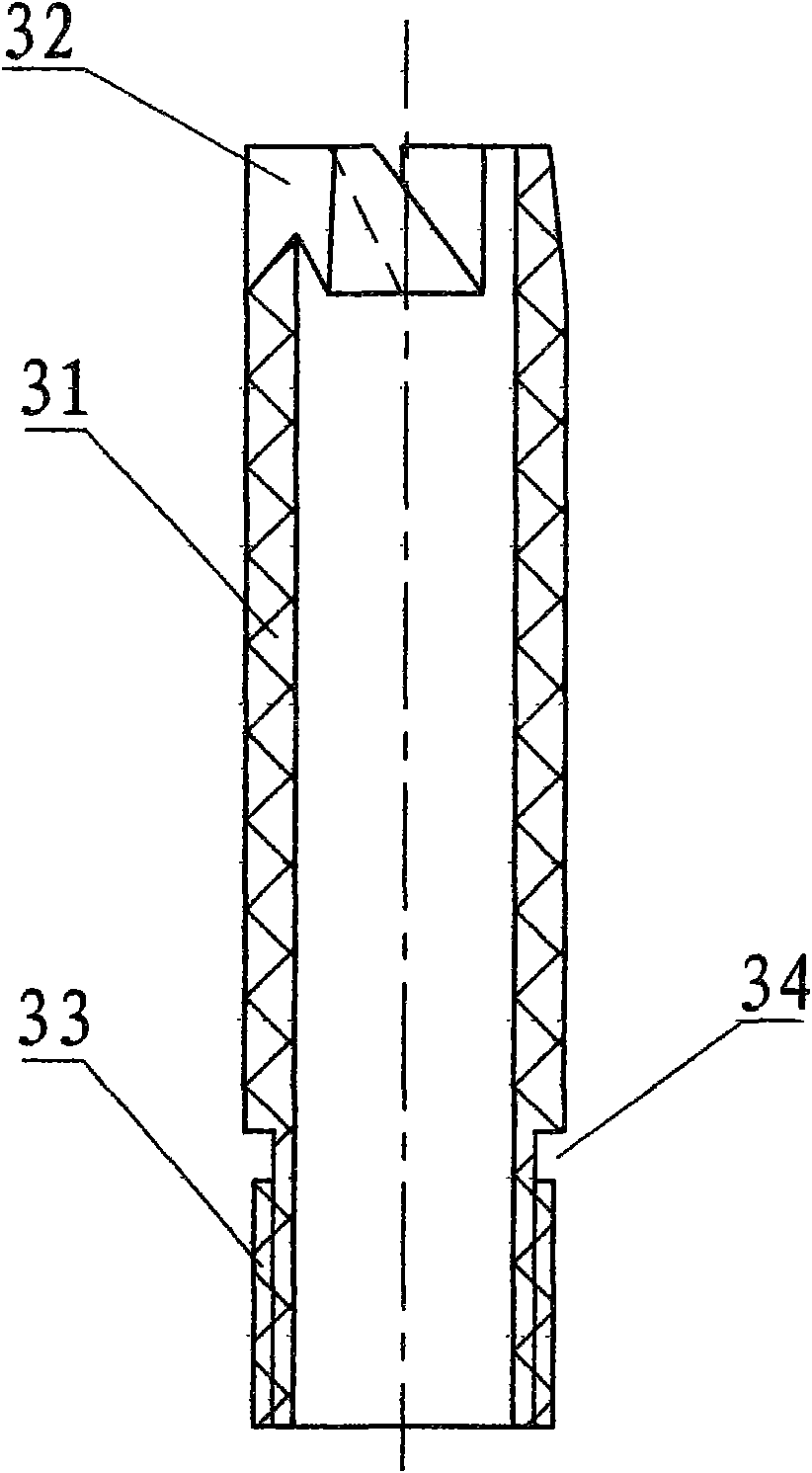

[0032] refer to Figure 1-3According to the present invention, the three-in-one hydrochloric acid synthesis furnace with graphite block hole type lower ignition includes a furnace body 1, a furnace base 2 is fixedly connected to the lower end of the furnace body 1, and a leg 3 is fixed at the lower end of the furnace base 2. A graphite base 4 is placed on the furnace base 2 in the furnace body 1, and a number of graphite block hole monomers 8 are successively accumulated on the graphite base 4. On the uppermost graphite block hole monomer 8, a gas The liquid distribution plate 21 is provided with a graphite furnace top cover 24 on the gas-liquid distribution plate 21 . A temperature measuring tube 23 extending into the gas-liquid mixing chamber 20 is arranged on the furnace body 1 . The graphite block hole unit 8 is provided with a cooling cavity 10 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com