Refrigerating tank container

A tank container and refrigeration system technology, applied in the field of containers, can solve problems such as inability to load and unload as a whole, increase risk factors, increase transportation costs and material loss, and achieve the effect of flexible loading and unloading and flexible transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

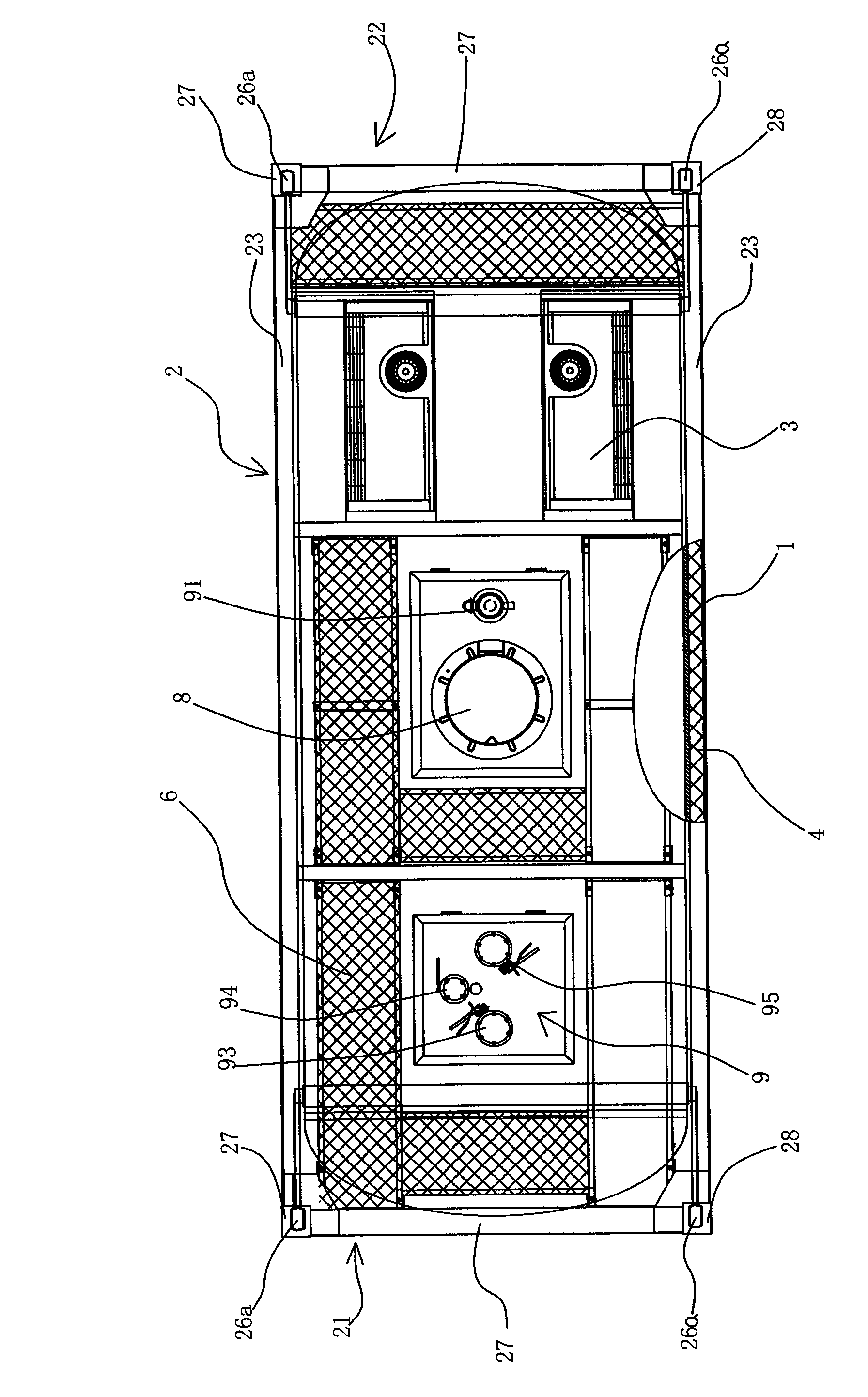

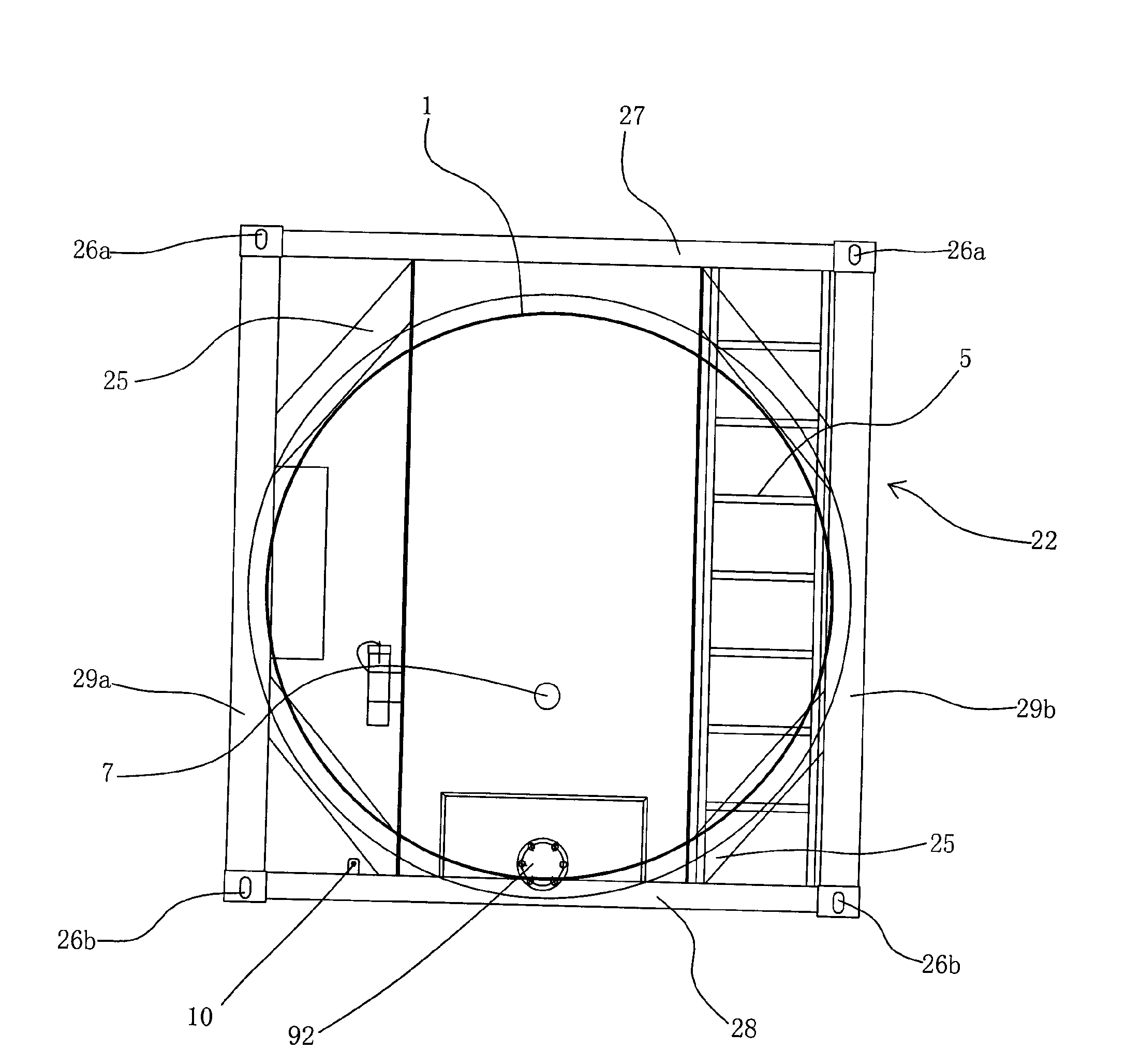

[0021] Such as figure 1 and figure 2 Shown in the figure, tank body 1; frame 2; front end frame 21; rear end frame 22; upper side beam 23; lower side beam 24; Beam 28; first column 29a; second column 29b; refrigeration system 3; heat insulation layer 4; ladder 5; walkway 6; Inlet and outlet valve 92; inlet and outlet valve 93; gas phase valve 94; steam valve 95;

[0022] This refrigerated tank container is suitable for road and sea transportation and intermodal transportation between these transportation methods. The carrying medium (such as beer, etc.) needs to maintain a certain temperature of non-dangerous liquid medium during transportation. It is mainly composed of frame 2, tank body 1, The refrigeration system 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com