Centralized driving flip-flow screen

A centralized drive and relaxation screen technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of difficulty in guaranteeing the reliability of the screen surface, fatigue damage of the crankshaft, and large vibration mass, etc., to achieve high screening efficiency, The effect of smooth movement and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

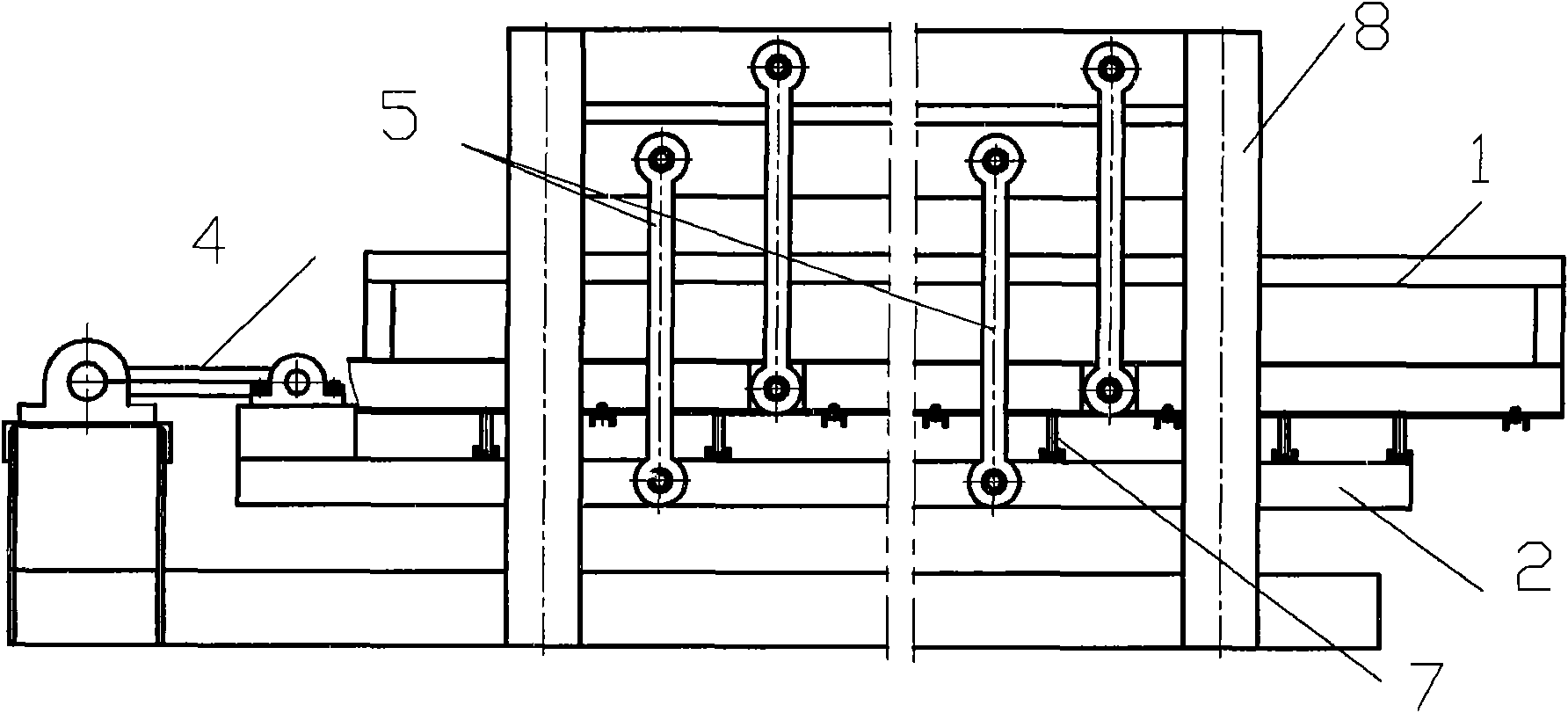

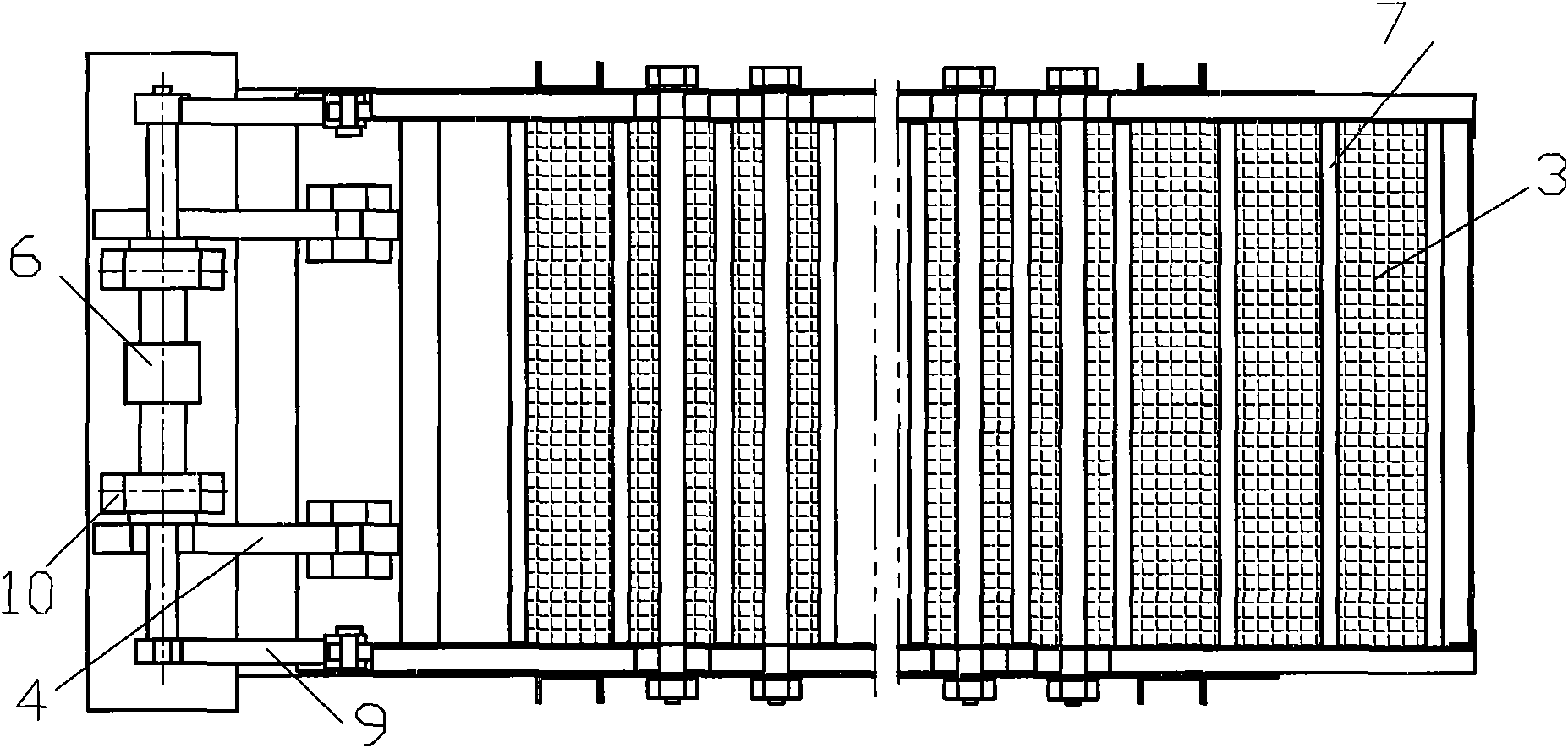

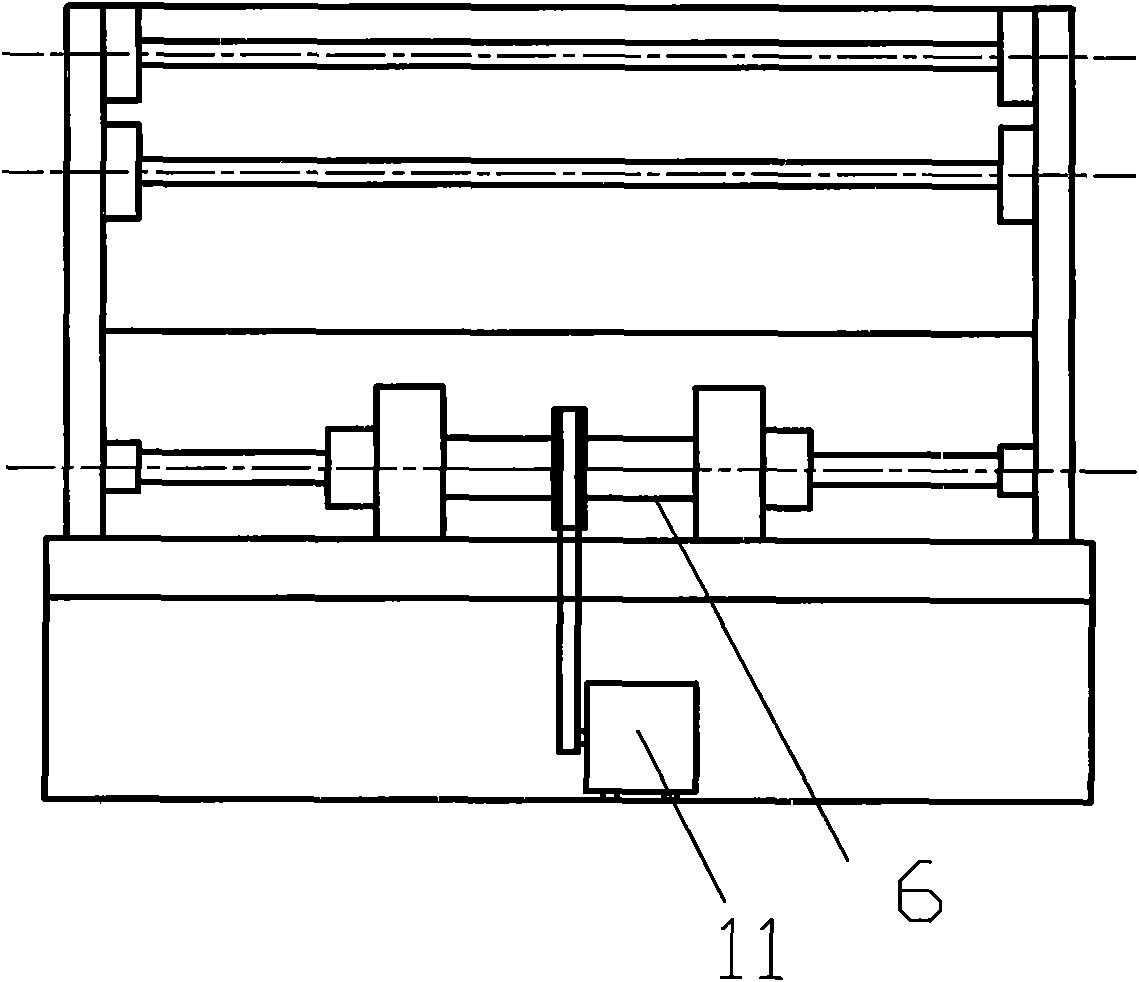

[0014] figure 1 figure 2 As shown, the centralized drive relaxation screen is mainly composed of an upper screen box 1, a lower screen box 2, a polyurethane elastic screen 3 connected by a plurality of small rectangular sieve plates, a transmission shaft 6 connecting the movement of the upper and lower screen boxes, a support frame 7 and The belt pulley transmission mechanism is composed. The quality of the upper screen box 1 and the lower screen box 2 are equal, and the upper and lower sides are respectively hinged and suspended on the frame 8 through the connecting rod 5 to form two upper and lower four-bar linkages. The hinge point of 5 swings slightly. Belt pulley transmission mechanism is located at the below of power transmission shaft 6 middle parts, and transmission mechanism comprises pulley motor 11, links to each other with transmission belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com