Slip ring device

A slip ring device and slip ring technology are applied in the field of rotary kilns to meet usage requirements and prevent gaps or deformations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention provides a thermocouple slip ring device, which is used to effectively prevent large gaps or deformation at the joint of the slip ring due to overheating and expansion of the rotary kiln cylinder, and can also meet the installation problem of the slip ring.

[0025] In order to facilitate the understanding of those skilled in the art, the structure and working principle of the slip ring device in the embodiment will be described in detail below with reference to the accompanying drawings.

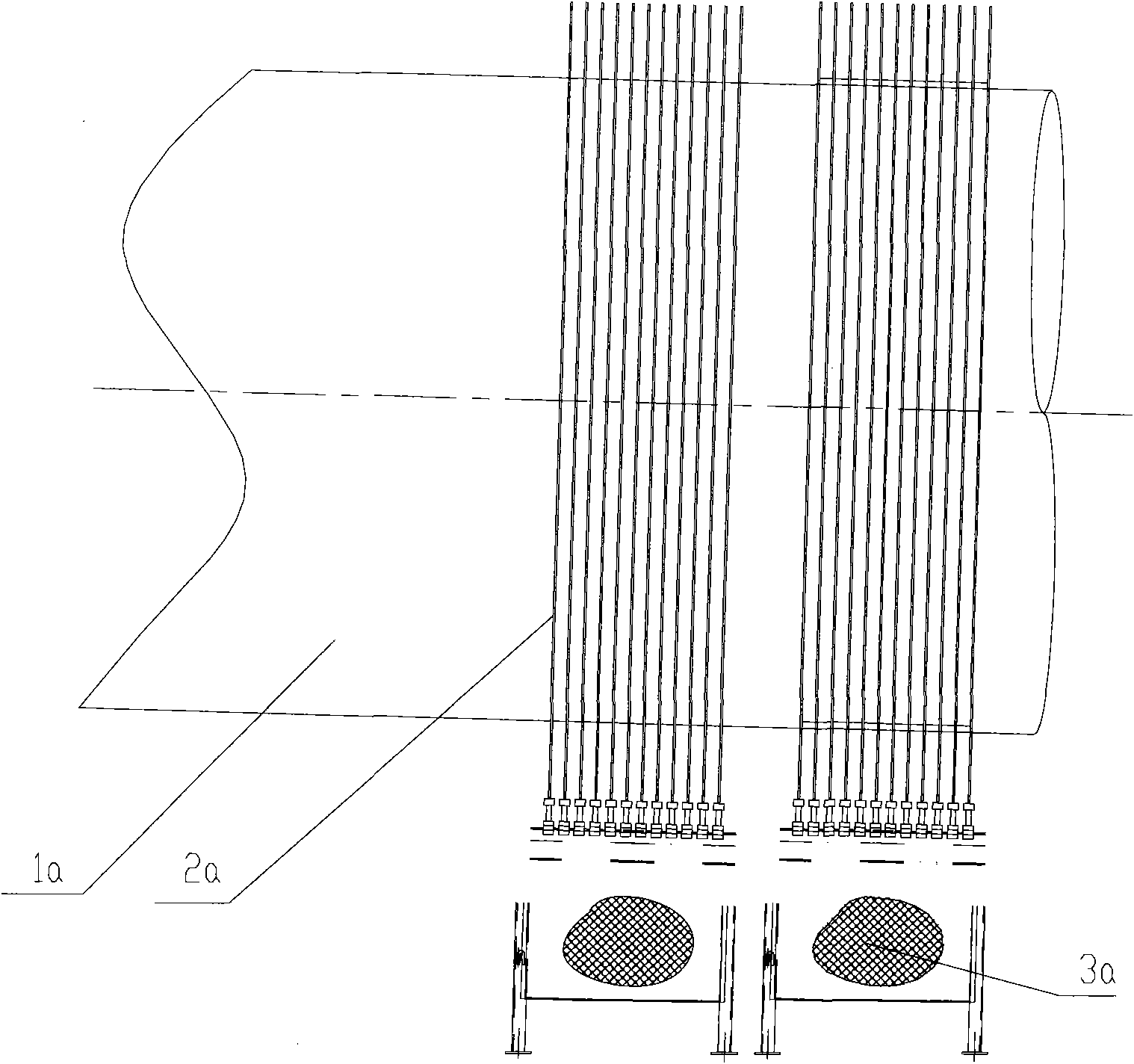

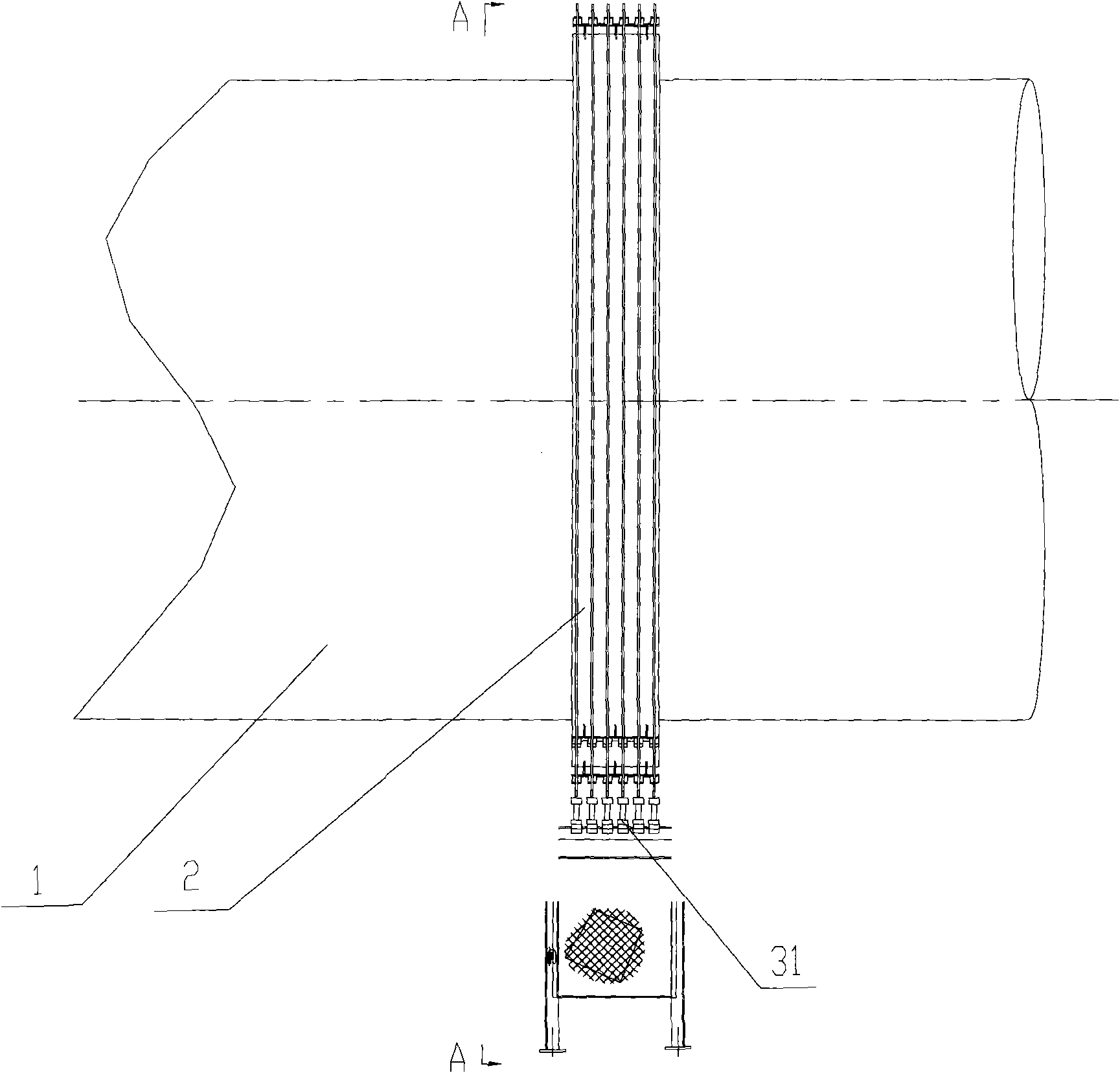

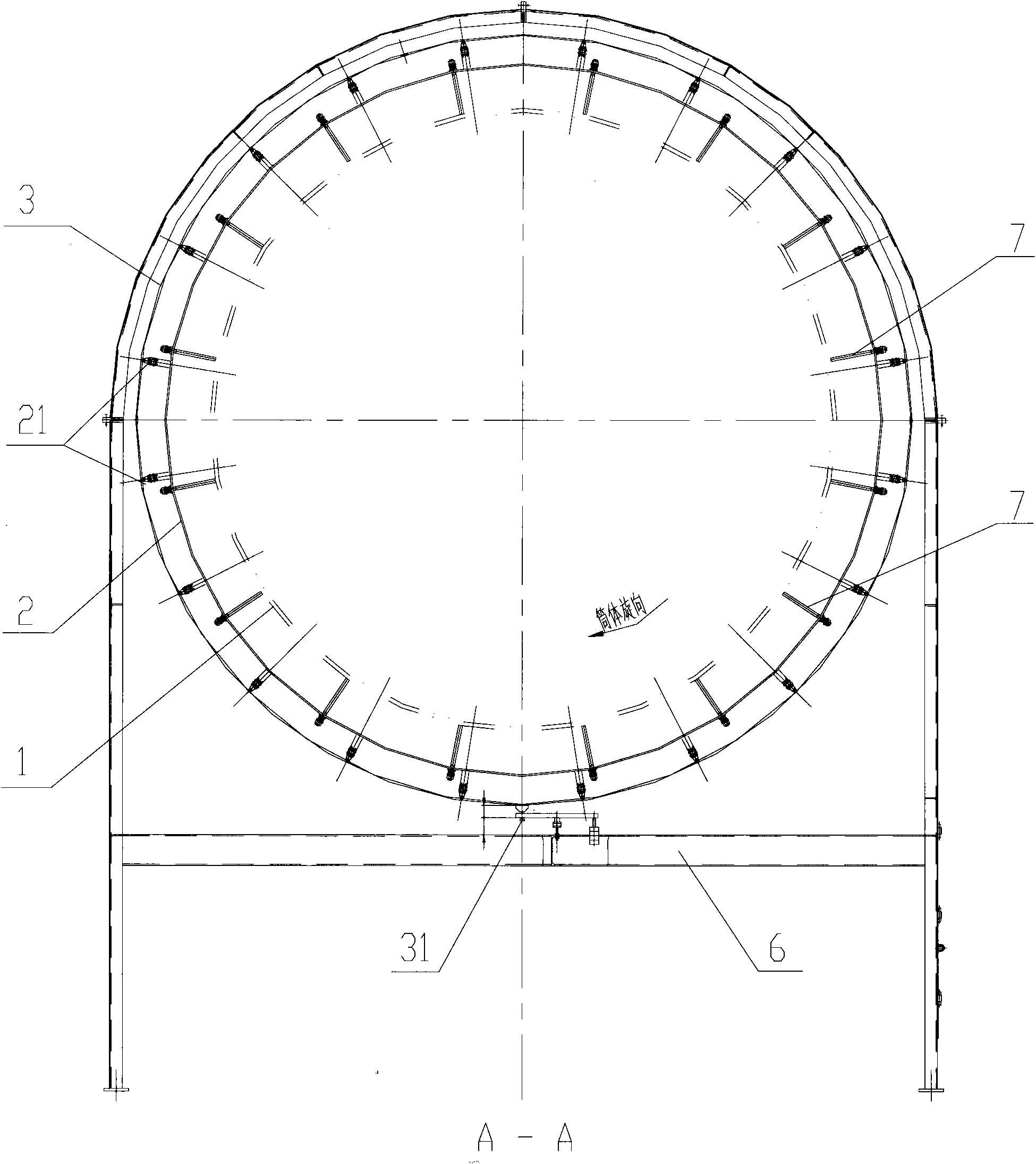

[0026] see figure 2 and image 3 , figure 2 It is the front view of the slip ring device according to the embodiment of the present invention; image 3 yes figure 2 Shown is the A-A sectional view.

[0027] The slip ring device in the embodiment of the present invention includes a heat insulating ring 2 fitted outside the rotary kiln shell 1 and at least one set of slip rings fitted outside the heat insulating ring 2 .

[0028] Each set of slip rings includes tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com