Explosion-proof connector

A connector and base technology, applied in the field of explosion-proof connectors, can solve the problems of casualties and property, flammable substances burning, affecting normal work, etc. The effect of loosening and ensuring normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

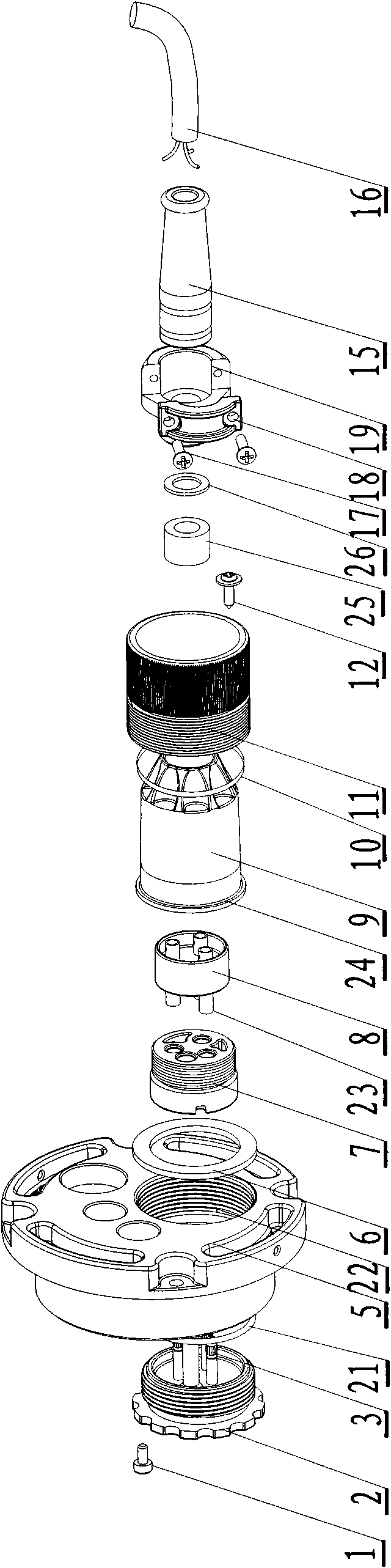

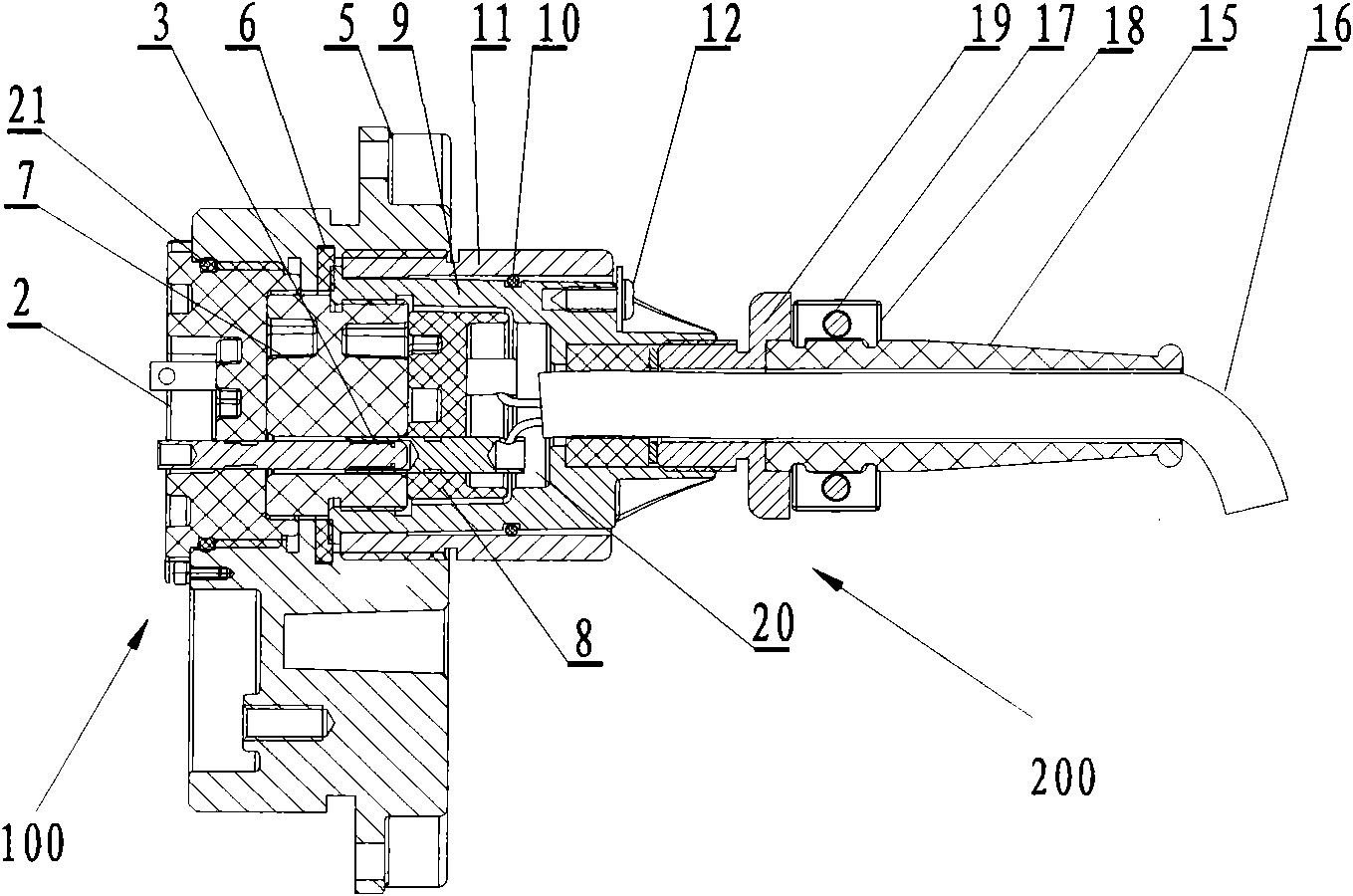

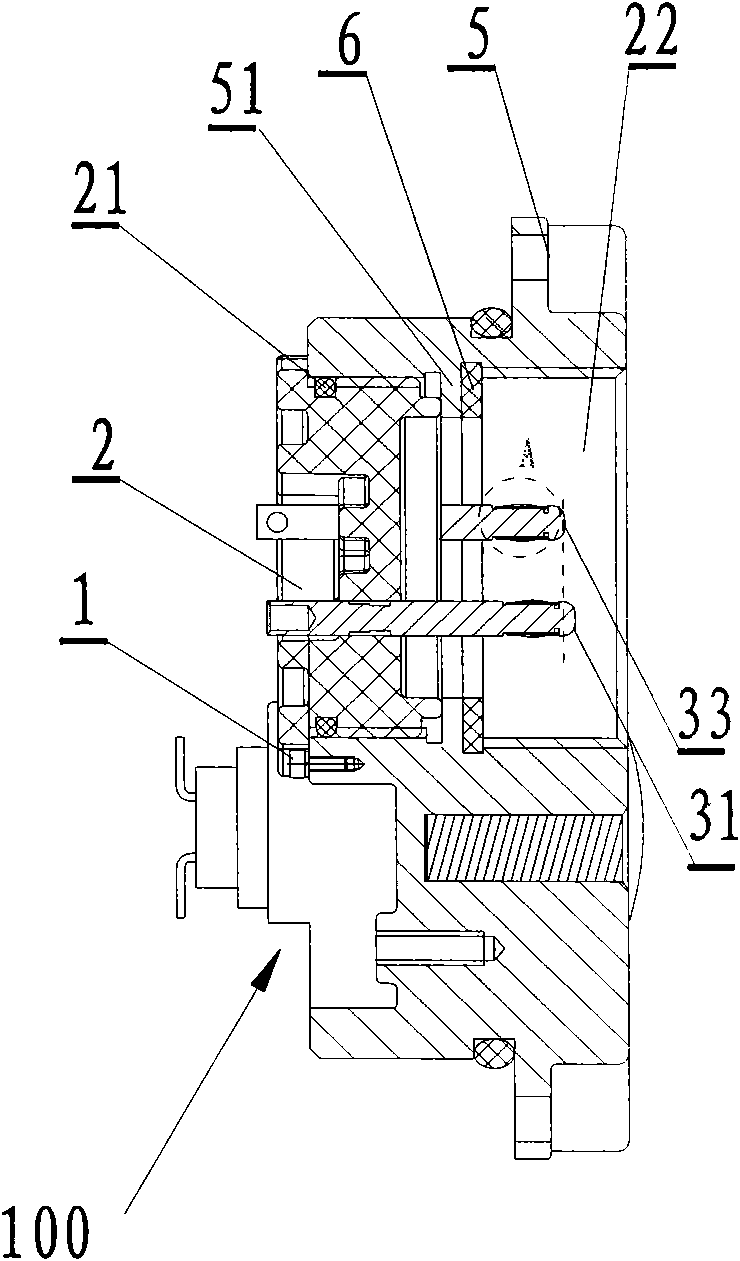

[0023] Such as figure 1 and figure 2 As shown, in a preferred embodiment of the explosion-proof connector of the present invention, the explosion-proof connector includes a receptacle 100 and a plug 200 mated with the receptacle 100 . Described socket 100 comprises socket base 5 and detachable tail cap 2, offers a through hole 22 on the socket base 5, is provided with internal thread in the through hole 22, and a step 51 is arranged in the middle of through hole 22, and through hole 22 Divided into two sections. Wherein, the first section is used for connecting the tail cap 2 , and the second section is used for connecting the plug 200 .

[0024] The tail cover 2 is provided with a boss, and the outer wall of the boss is provided with an external thread, which is adapted and screwed with the internal thread of the first section of the through hole 22 . The edge of the tail cover 2 is provided with a plurality of arc-shaped gaps. After the tail cover 2 is screwed to the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com